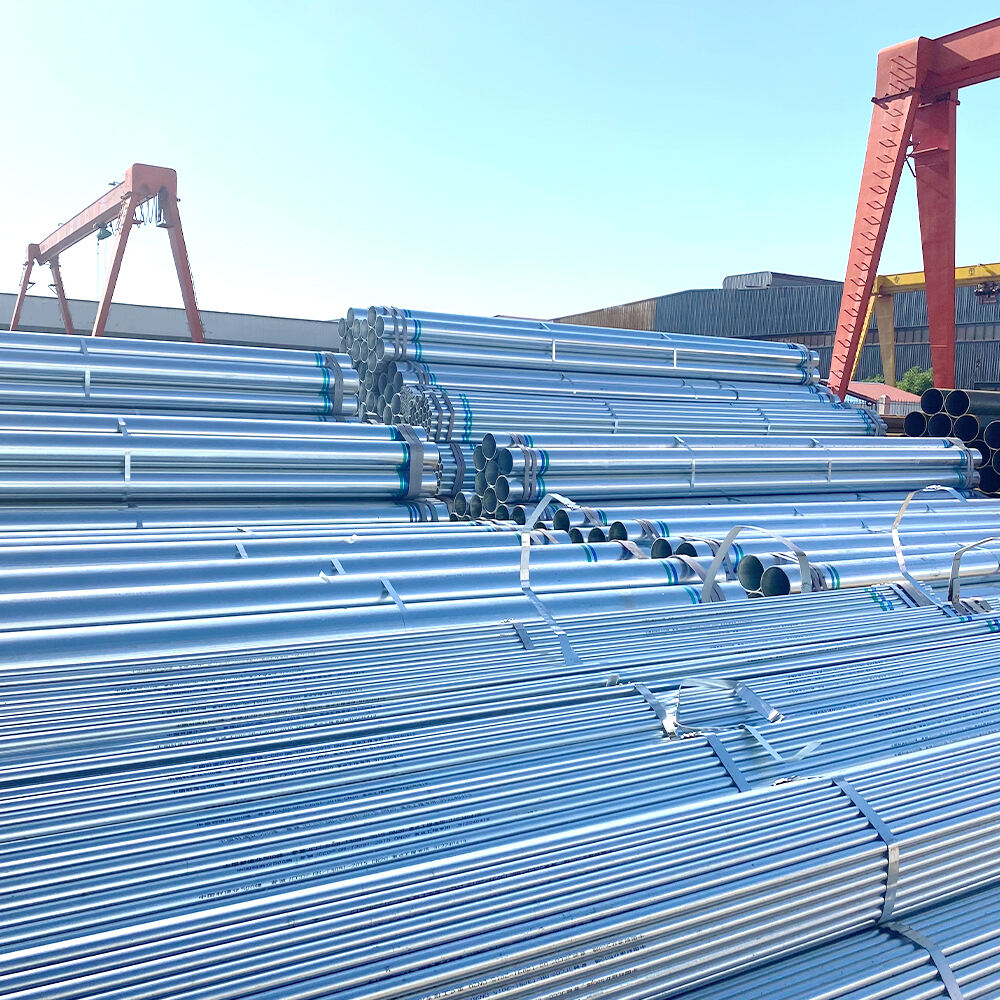

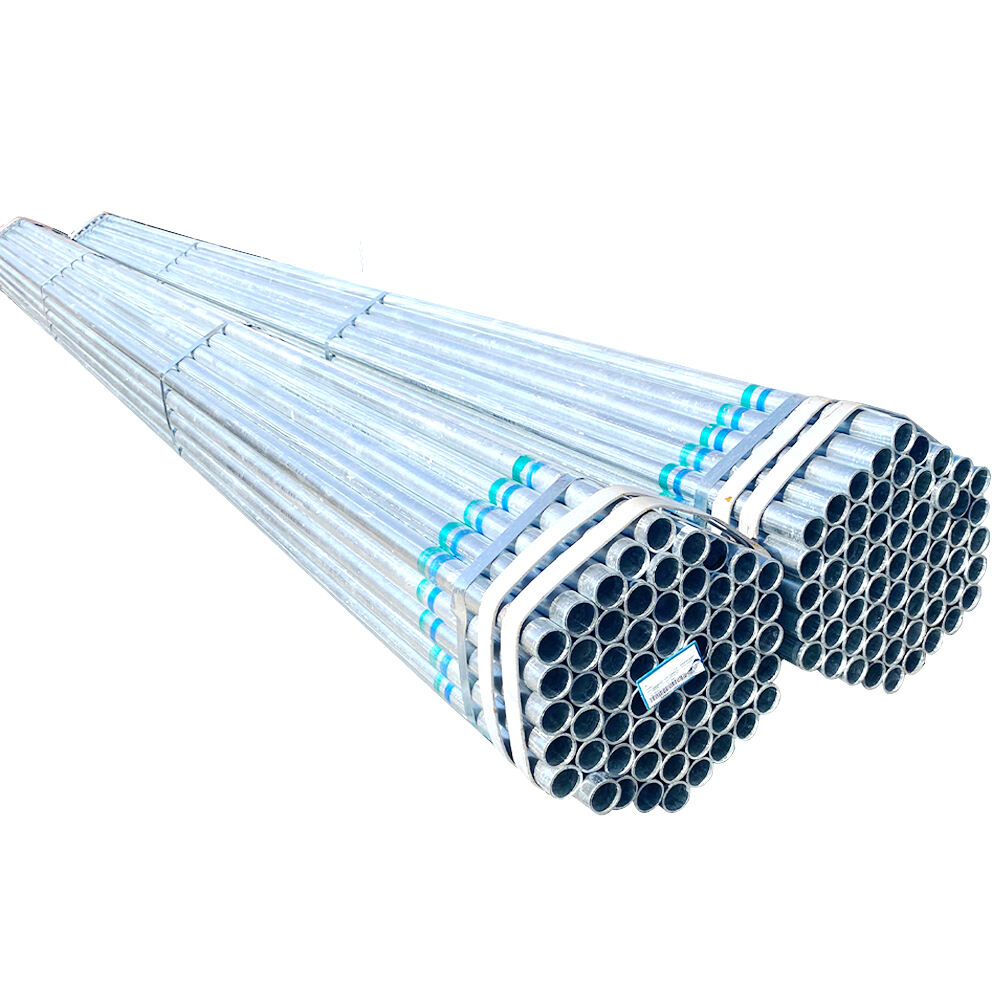

tuba e çeliku të galvanizuar

Tubi i çelikut të galvanizuar përfaqëson një inovacion të rëndësishëm në ndërtim dhe aplikime industriale, duke kombinuar qëndrueshmërinë me rezistencën ndaj korrozionit përmes një procesi të avancuar të përtypjes me zink. Këtë tub special e pëson galvanizimi me të ftohurin e nxehtë, ku çeliku përfshihet në zink të shkrirë në temperaturë prej rreth 840°F, duke krijuar një shtresë mbrojtëse të lidhur metalurgjikisht. Shtresa rezultuese e zinkut vepron si barierë e sakrifikuar, duke mbrojtur çelukun nënshtruar nga ndotja dhe korrozioni, ndërkohë që mban integritetin strukturor të tubit. Këta tuba janë të projektuar të qëndrojnë në kushte të ashpra mjedisore, duke përfshirë ekspozimin ndaj ujit, kimikateve dhe temperaturave të ndryshueshme. Procesi i galvanizimit jo vetëm që e rrit jetën e tubit, por ofronë gjithashtu një sipërfaqe të lemuar dhe uniforme që zvogëlon fërkimin në aplikimet e transportit të lëngjeve. Aplikimet e zakonshme përfshijnë sistemet e shpërndarjes së ujit, sistemet e sprinklerëve të zjarrit, mbështetjen strukturale në ndërtesa dhe të gjitha llojet e proceseve industriale. Procesi i standardizuar i prodhimit garanton cilësi të përsëritshme dhe performancë të besueshme, me tuba të disponueshëm në diametra dhe trashësi të ndryshme të mureve për t'u përshtatur me kërkesat e ndryshme të presionit dhe aplikimeve. Galvanizuesit modernë të çelikut shpesh përfshijnë teknologji të avancuara të përtypjes që e rrisin edhe më shumë rezistencën e tyre ndaj ekspozimit kimik dhe dëmtimit mekanik.