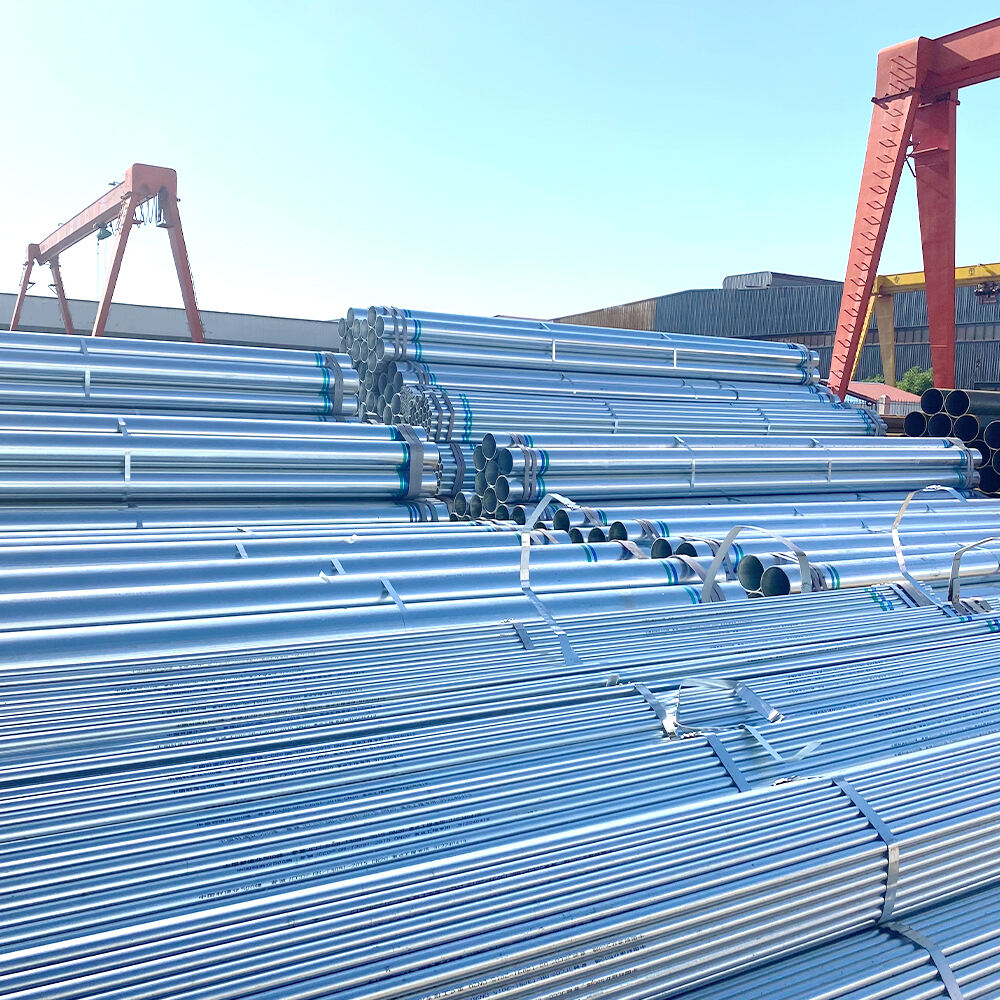

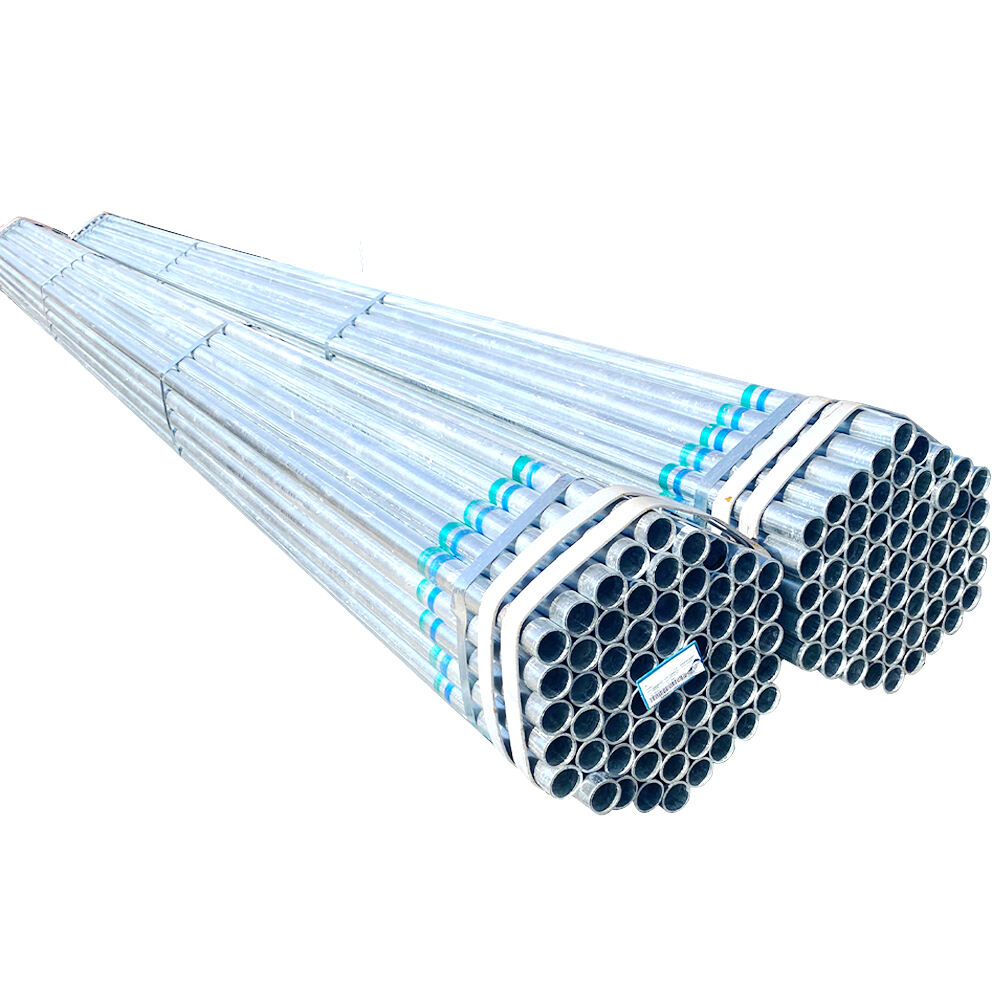

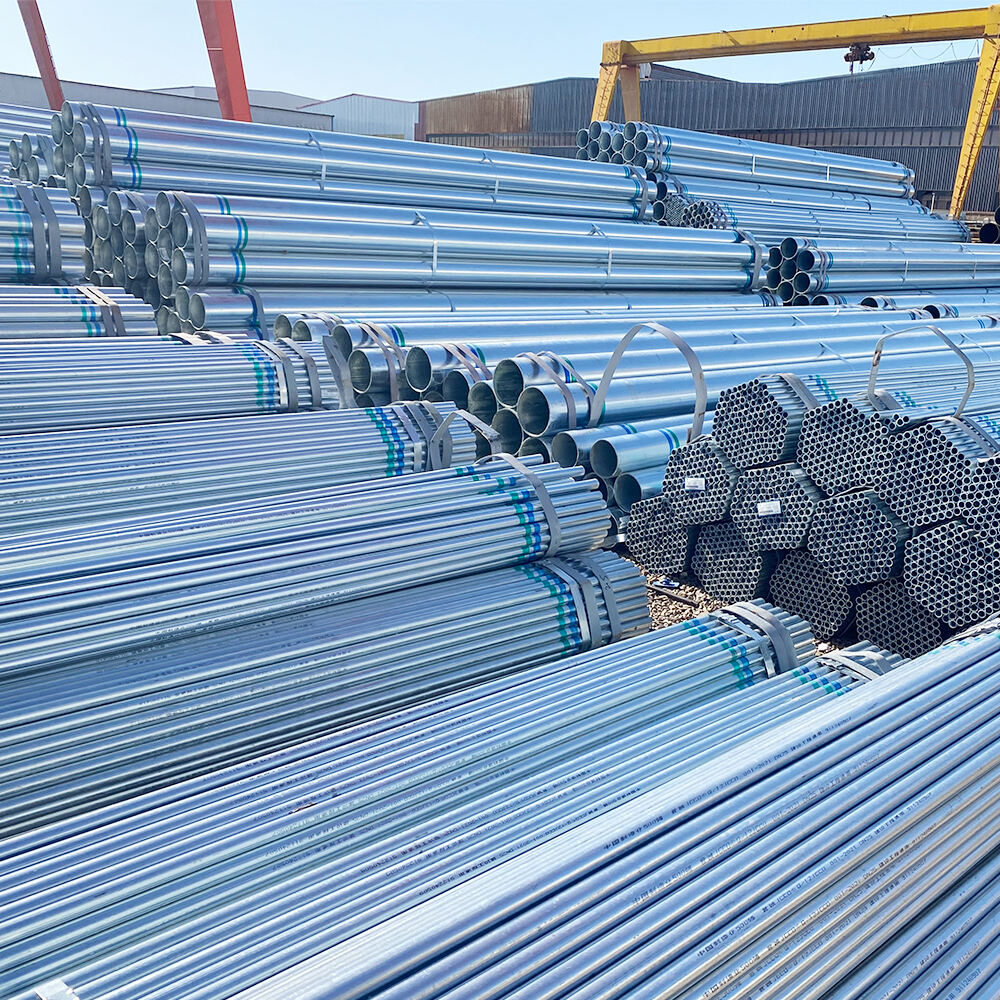

tub metalik i galvanizuar

Tubat e metaleve të galvanizuara paraqesin një gur themeli në ndërtimin modern dhe aplikimet industriale, duke ofruar mbrojtje superiore kundër korrozionit përmes një shtresë mbrojtëse zinku. Këto tuba nënshqiqen një proces special të galvanizimit me zink të nxehur ku tubat e çelikut apo të hekurit ijinë në zink të shkrirë në temperatura rreth 860°F (460°C), duke krijuar një shtresë të lidhur metalurgjikisht që e mbrojtë metalin bazë nga faktorët ambientalë. Shtresa e zinkut që rezulton ofron jo vetëm mbrojtje të barrierës por edhe mbrojtje të sakrifikimit, që do të thotë se zinku do të korrodohet paraprakisht për të mbrojtur çelikun nënshtruar. Këto tuba gjejnë përdorim të gjerë në sistemet e shpërndarjes së ujit, mbështetësit strukturorë, tubacionet elektrike dhe një larmi aplikimesh industriale. Procesi i galvanizimit krijon një shtresë të njëtrajtshme dhe të ngjitur që zakonisht zgjat 20-25 vjet në mjedise normale, duke e rritur konsiderueshëm kohën e shfrytëzimit të tubit metalik. Trashësia e shtresës së zinkut mund të personalizohet sipas kërkesave të veçanta, zakonisht në intervalin 45 deri në 100 mikronë. Tubat modernë të galvanizuar kanë gjithashtu cilësi të përmirësuara të shtresës së sipërfaqes, saktësi të përcaktuar dimensionale dhe aftësi të kryer të lidhjes me të tjera, duke i bërë të përshtatshëm për aplikime si në interier ashtu edhe në eksterier.