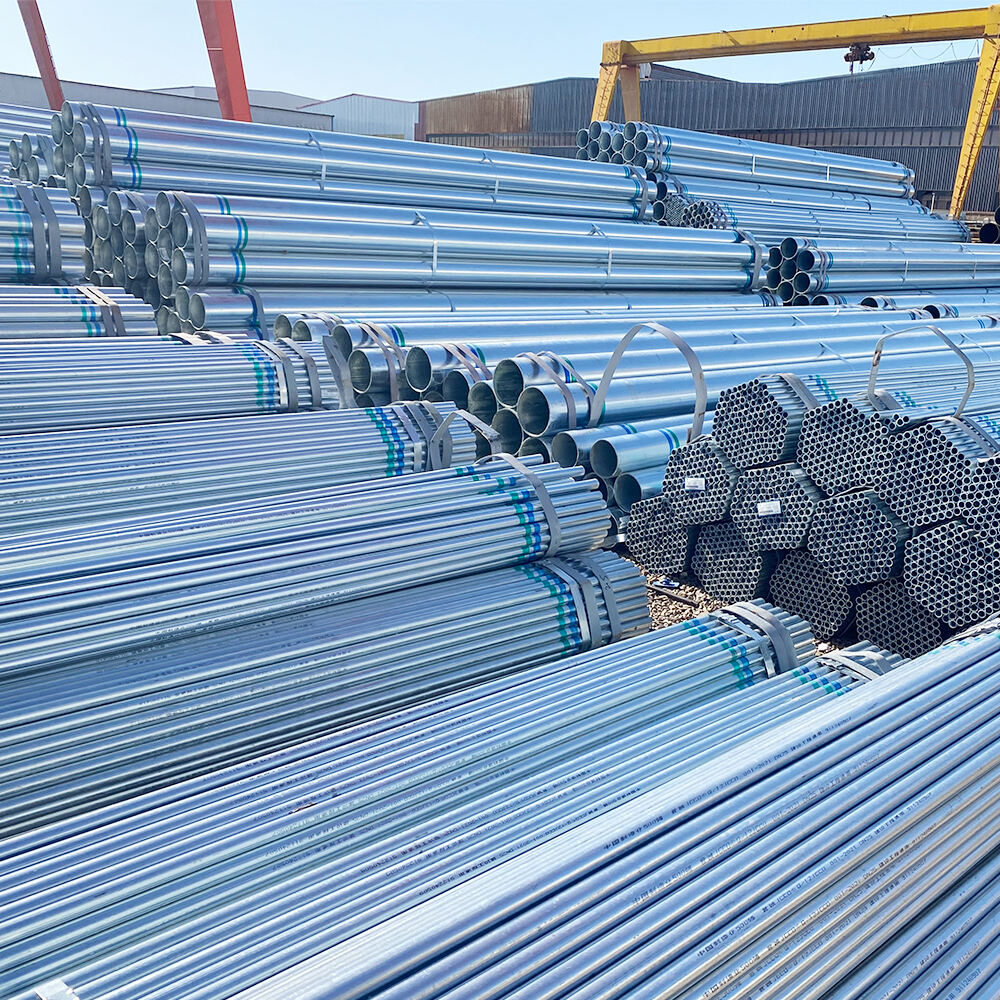

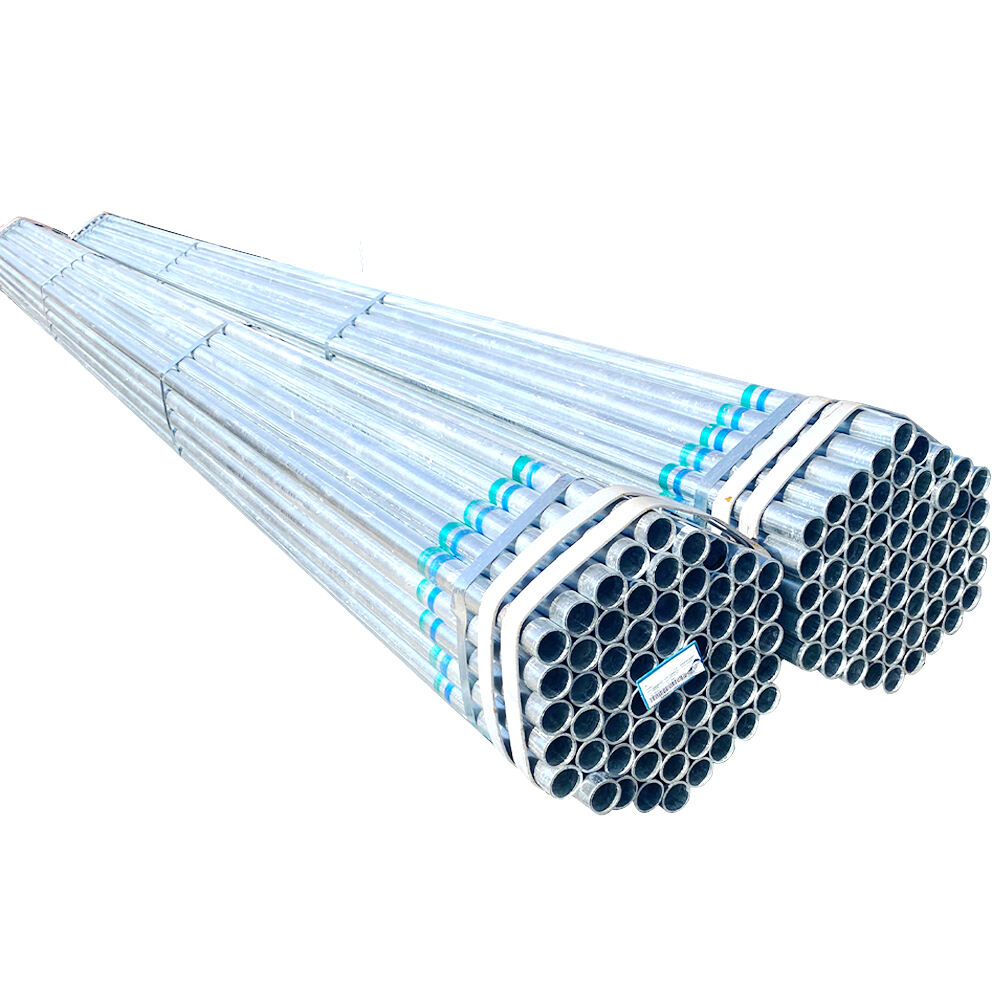

prerje e tubit të çelikut të galvanizuar

Gypsi prej çeliku të galvanizuar paraqesin një komponent të rëndësishëm në ndërtimet dhe aplikimet industriale moderne, duke ofruar qëndrueshmëri dhe vershtësi të jashtëzakonshme. Kjo gypsi e specializuar kalon nëpër një proces sofistikuar galvanizimi ku një shtresë mbrojtëse zinku aplikohet në sipërfaqen e çelikut para se të presohet në specifikime të sakta. Galvanizimi krijon një barrierë të fortë kundër korrozionit dhe karrosionit, duke zgjatur kështu kohën e shfrytëzimit të gypsit. Procesi i prerjes përdor metoda teknologjike të avancuara, përfshirë prerjen mekanike apo me laser të saktë, duke siguruar matje të sakta dhe skaje të pastra për aplikime të ndryshme. Këto gypsa prodohen për të përmbushur standarde të rrepta industriale, duke përfshirë trashësinë e njëtrajtshme të shtresës së zinkut dhe matjet e njëtrajtshme të diametrit të brendshëm. Gypsat e çelikut të galvanizuar kanë raport të jashtëzakonshëm fortësie- peshë, gjë që i bën ata idealë për aplikime strukturore dhe jashtë strukturore. Ata dallohen në mjedise të ndryshme, nga sistemet e ujësjellësit brenda shtëpive deri te projekte infrastrukturore jashtë, duke mbajtur integritetin edhe në kushte të vështira. Kombinimi i shtresës mbrojtëse prej zinku dhe thelbit të çelikut të lartë garanton performancën optimale në sistemet e shpërndarjes së ujit, sistemet e ujësjellësit për zjarr dhe aplikime mbështetëse strukturore. Proceset moderne të prodhimit lejojnë gjatësi dhe diametra të personalizuar, duke i përshtatur kërkesave specifike të projektit duke mbajtur efektivitetin ekonomik.