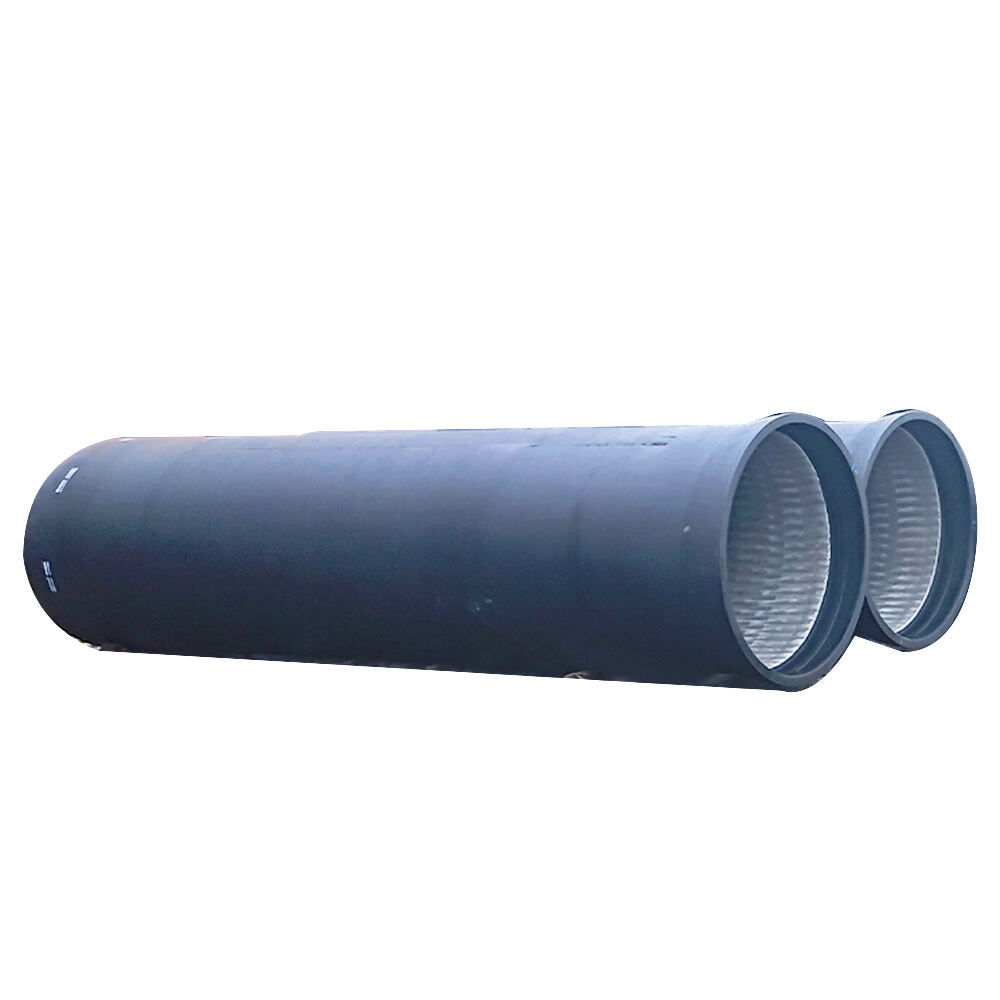

tubo in ghisa ductile rivestito in cemento

I tubi in ghisa sferoidale rivestiti con malta di cemento rappresentano un'importante innovazione nei moderni sistemi di tubazioni, unendo le eccellenti proprietà meccaniche della ghisa sferoidale alle qualità protettive del rivestimento in malta di cemento. Questa soluzione avanzata di tubazione è composta da un'anima in ghisa sferoidale che garantisce una notevole resistenza e flessibilità, mentre il rivestimento interno in cemento offre una superiore protezione contro la corrosione e assicura il mantenimento della qualità dell'acqua nel lungo termine. La struttura del tubo è costituita da tre componenti principali: il substrato in ghisa sferoidale, che fornisce elevata resistenza a trazione e resistenza agli urti, il rivestimento in malta di cemento che previene la corrosione interna e mantiene l'efficienza del flusso, e spesso un rivestimento esterno per una protezione aggiuntiva. Questi tubi vengono prodotti attraverso un processo di fusione centrifuga, seguito da un'applicazione precisa del rivestimento in malta di cemento in condizioni controllate. Questa tecnologia è particolarmente apprezzata nei sistemi idrici municipali, nelle applicazioni industriali e nella gestione delle acque reflue grazie alla sua comprovata affidabilità e durata. Con diametri che vanno generalmente da 3 a 64 pollici, questi tubi sono in grado di soddisfare svariate esigenze di portata e pressione, rendendoli adatti sia per reti di distribuzione che per linee di trasmissione. Il rivestimento in cemento riduce significativamente l'attrito, mantiene portate costanti e previene la tubercolizzazione, assicurando un'ottimale performance idraulica per tutta la vita del sistema.