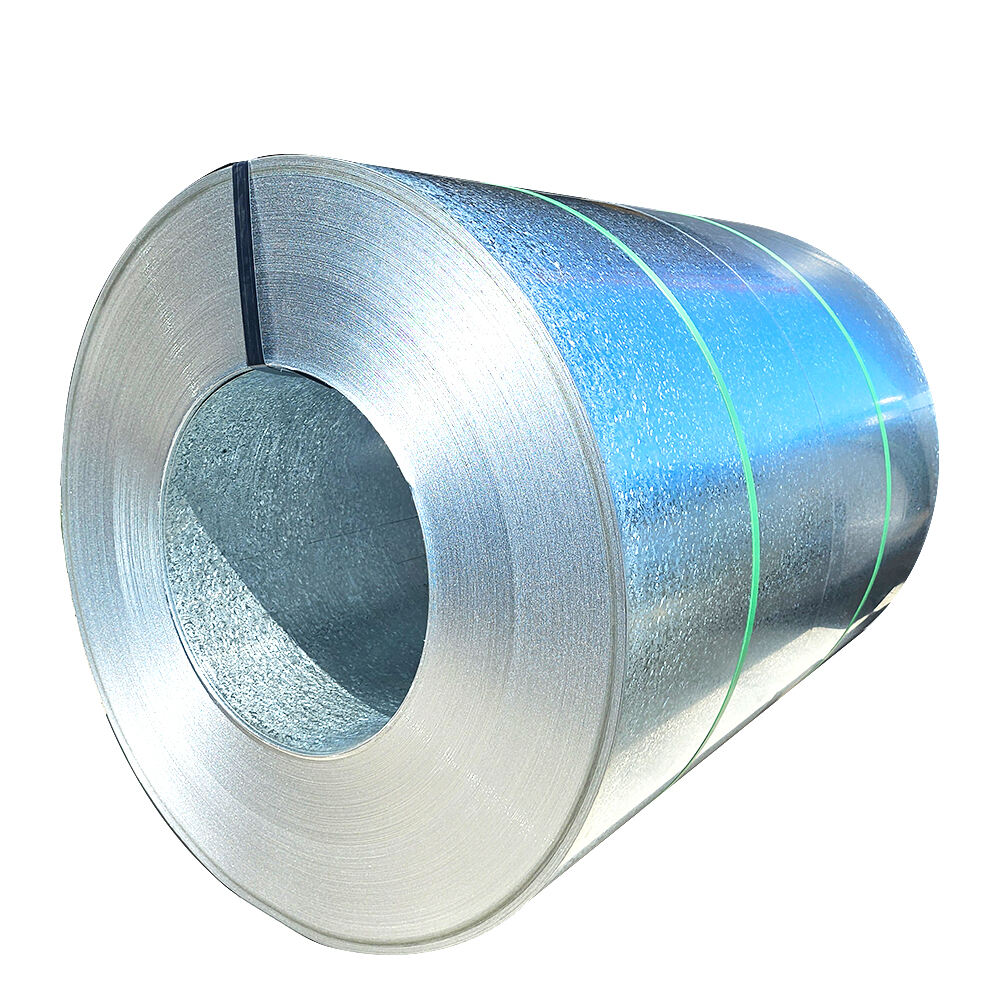

bobina de acero galvanizado

La bobina de acero galvanizado representa un avance crucial en la tecnología de protección de metales, combinando durabilidad con versatilidad en la construcción y fabricación modernas. Este material innovador consiste en láminas o tiras de acero que pasan por un proceso especial de recubrimiento, en el cual se aplica zinc para crear una barrera protectora. El proceso de galvanización implica sumergir el acero en zinc fundido a una temperatura de aproximadamente 860°F (460°C), formando un enlace metalúrgico que protege al metal base contra la corrosión. El recubrimiento de zinc resultante no solo proporciona una resistencia superior a la oxidación y la corrosión, sino que también ofrece protección catódica, lo que significa que el zinc se corroe preferentemente para proteger al acero subyacente. Estas bobinas se fabrican en diversos espesores y anchos para adaptarse a diferentes aplicaciones industriales, desde materiales de construcción hasta componentes automotrices. El espesor del recubrimiento puede controlarse con precisión durante la producción, generalmente oscilando entre G30 y G210, lo cual indica la cantidad de zinc aplicado por metro cuadrado. Las bobinas modernas de acero galvanizado también incorporan técnicas avanzadas de procesamiento que garantizan una distribución uniforme del recubrimiento y un acabado superficial mejorado, haciéndolas ideales tanto para aplicaciones funcionales como estéticas. La excepcional durabilidad del material, junto con su rentabilidad, lo ha convertido en un componente indispensable en numerosas industrias, especialmente en entornos donde la exposición a la humedad y al clima representan desafíos significativos.