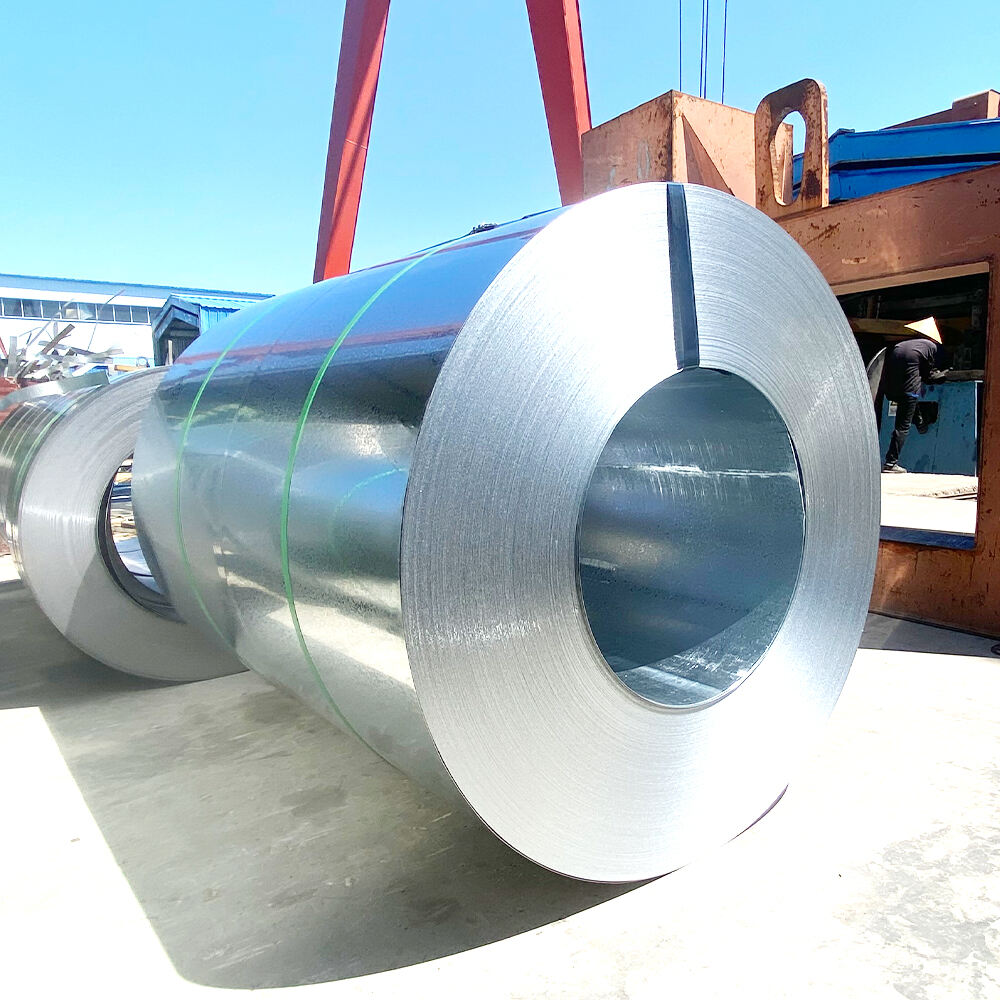

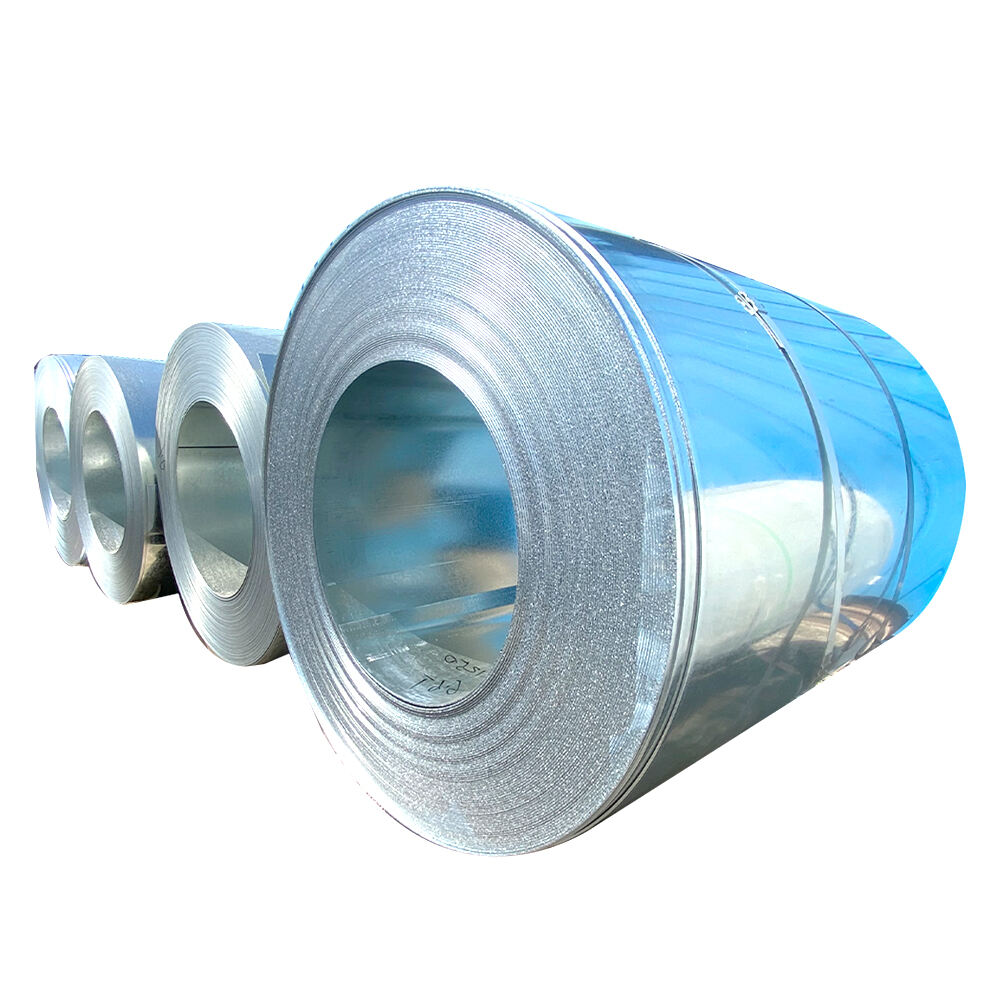

de las partidas de las placas de metal galvanizadas

Las bobinas de chapa galvanizada representan un componente fundamental en la construcción y fabricación modernas, ofreciendo una excepcional resistencia a la corrosión y durabilidad gracias a su superficie recubierta de zinc. Estas bobinas se producen mediante un proceso sofisticado de galvanizado por inmersión en caliente, en el cual las láminas de acero se sumergen en zinc fundido a temperaturas cercanas a los 860°F. Este tratamiento crea una capa protectora unida metalúrgicamente que protege al metal base de los factores ambientales. El recubrimiento está compuesto por varias capas de aleación zinc-hierro, culminando en una capa exterior de zinc puro que proporciona una protección superior contra la oxidación y el óxido. Estas bobinas están disponibles en diversos espesores y anchos, lo que las hace versátiles para múltiples aplicaciones. Sus aplicaciones principales abarcan la construcción, la fabricación automotriz, los sistemas de calefacción, ventilación y aire acondicionado (HVAC), y el equipo agrícola. El recubrimiento de zinc no solo protege al sustrato de acero, sino que también ofrece propiedades autorreparadoras, en las que los pequeños arañazos quedan protegidos por el recubrimiento de zinc circundante a través de acción galvánica. Las bobinas modernas de chapa galvanizada también presentan tratamientos superficiales mejorados que incrementan la adherencia de pinturas y las características de resistencia a la intemperie, haciéndolas ideales tanto para aplicaciones interiores como exteriores.