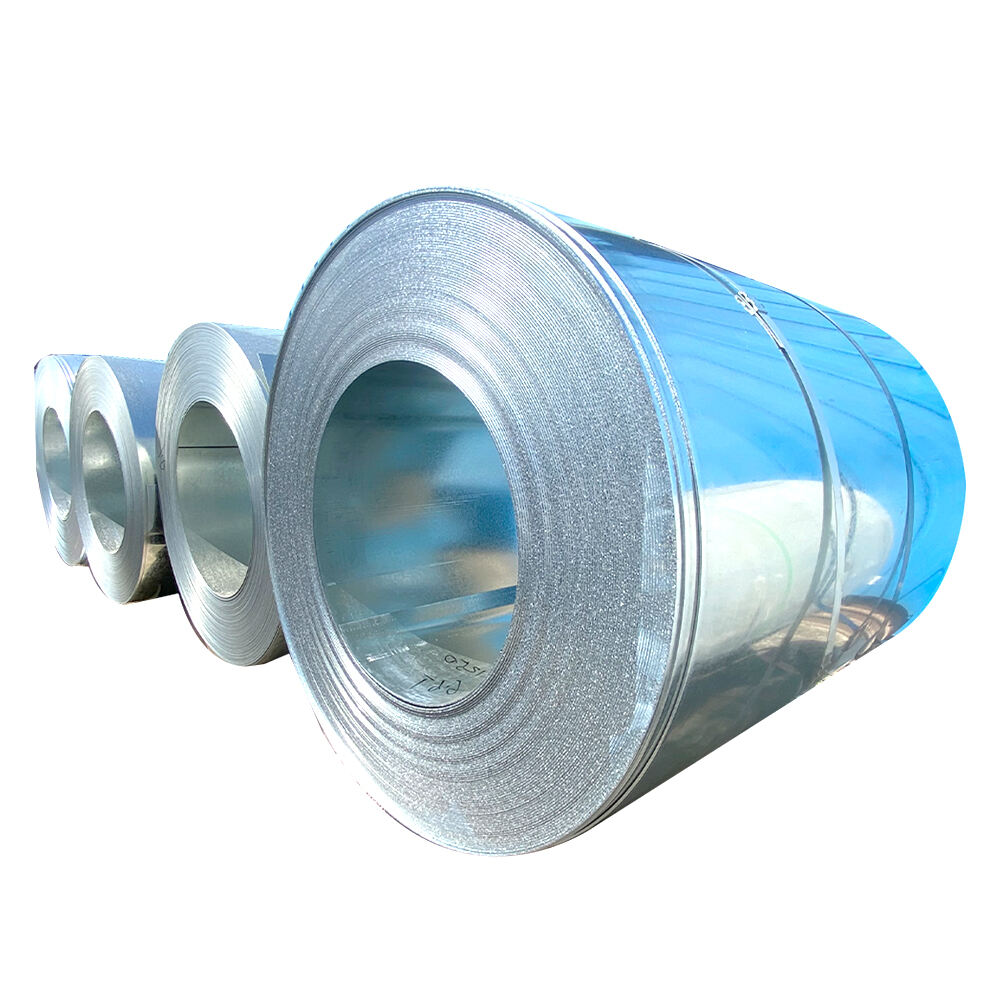

heißgetauchte verzinkte Stahlcoils

Feuerverzinkte Stahlspulen stellen ein hochwertiges Stahlprodukt dar, das durch einen fortschrittlichen metallurgischen Prozess hergestellt wird, bei dem Stahlbänder in flüssiges Zink eingetaucht werden. Dieser Beschichtungsprozess erzeugt eine metallurgisch gebundene Zink-Schicht, die eine hervorragende Korrosionsbeständigkeit und eine verlängerte Lebensdauer gewährleistet. Der Prozess umfasst die Reinigung der Stahloberfläche, gefolgt vom Eintauchen in ein Bad mit flüssigem Zink bei etwa 860 °F (460 °C). Während dieses Vorgangs reagiert das Zink mit der Stahloberfläche und bildet mehrere Zink-Eisen-Legierungsschichten, die in einer äußeren reinen Zinkschicht münden. Die resultierende Beschichtung bietet ein charakteristisches Schimmermuster und eine widerstandsfähige Schutzbarriere gegen Umwelteinflüsse. Diese Spulen finden breite Anwendung in verschiedenen Branchen, einschließlich des Bauwesens, der Automobilindustrie und der Infrastruktur-Entwicklung. Die Schichtdicke kann präzise gesteuert werden, um spezifische Industriestandards und Kundenanforderungen zu erfüllen, üblicherweise im Bereich von G30 bis G235. Die Vielseitigkeit feuerverzinkter Stahlspulen macht sie ideal für den Einsatz im Innen- und Außenbereich, insbesondere in Umgebungen, in denen eine hohe Korrosionsbeständigkeit erforderlich ist. Die Langlebigkeit des Produkts in Verbindung mit Kosteneffizienz und geringem Wartungsaufwand hat es zu einem Schlüsselmaterial in modernen Industrieanwendungen gemacht.