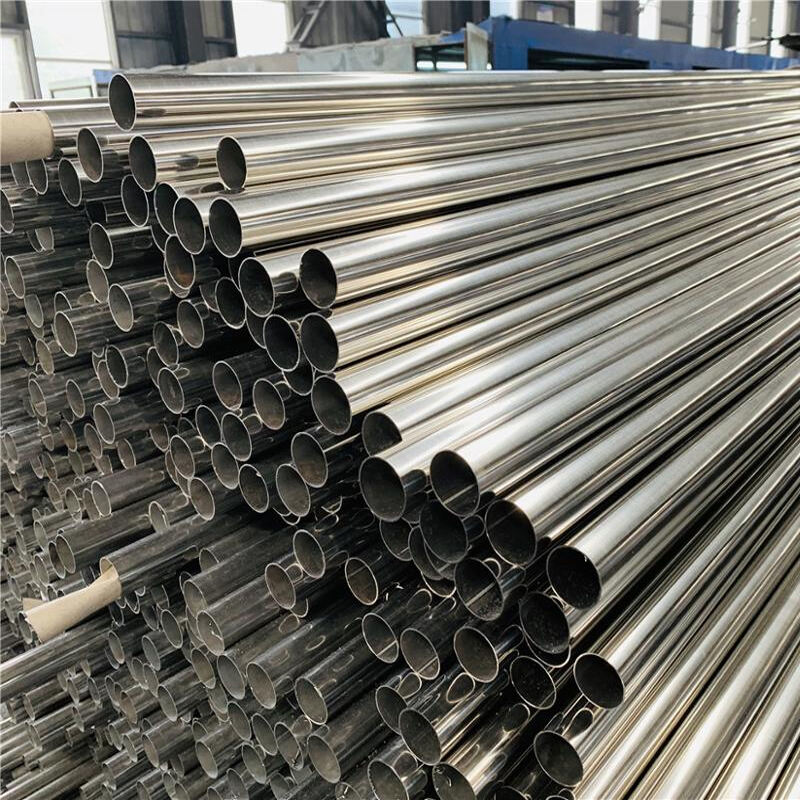

mga diameter ng stainless steel pipe

Ang mga sukat ng diameter ng stainless steel na tubo ay nagsasaad ng mahalagang aspeto ng mga industriyal at komersyal na sistema ng tubo, na nag-aalok ng isang komprehensibong hanay ng mga sukat upang umangkop sa iba't ibang aplikasyon. Karaniwan, ang mga diameter na ito ay nasa saklaw mula sa maliit na tubo na 1/8 pulgada hanggang sa malalaking tubo na higit sa 24 pulgada. Ang pamantayan ng mga diameter na ito ay sumusunod sa mga internasyonal na espesipikasyon, kabilang ang ASTM at DIN na mga pamantayan, upang tiyakin ang pandaigdigang pagkakatugma at katiyakan. Ang tumpak na pagpapakita ng mga sukat ng diameter, parehong panloob at panlabas, ay gumaganap ng mahalagang papel sa pagpapanatili ng kahusayan ng daloy, rating ng presyon, at integridad ng sistema. Ang mga modernong proseso ng pagmamanupaktura ay gumagamit ng makabagong teknolohiya upang makamit ang maigting na toleransiya sa mga espesipikasyon ng diameter, na nagreresulta sa mataas na kalidad ng pagganap. Ang mga tubong ito ay malawakang ginagamit sa iba't ibang industriya, mula sa pagproseso ng pagkain at pagmamanupaktura ng gamot hanggang sa mga kemikal na halaman at proyekto sa konstruksyon. Ang ugnayan sa pagitan ng diameter ng tubo at kapal ng pader ay maingat na ininhinyero upang magbigay ng optimal na lakas habang pinapanatili ang gastos na epektibo. Ang iba't ibang mga rating ng schedule, tulad ng Schedule 10, 40, at 80, ay nag-aalok ng iba't ibang kapal ng pader para sa parehong nominal na diameter, na nagbibigay-daan sa mga gumagamit na pumili ng pinakaangkop na espesipikasyon para sa kanilang tiyak na mga pangangailangan.