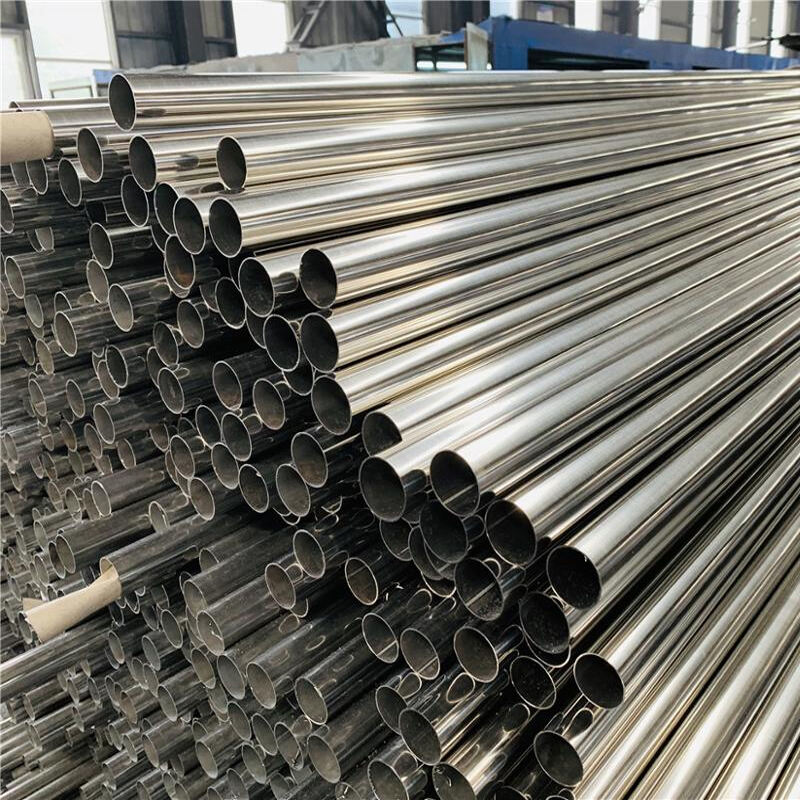

stainless Steel Pipe

Ang bakal na hindi kinakalawang na tubo ay nagsisilbing pinakapangunahing bahagi sa modernong aplikasyon sa industriya at konstruksyon, na nag-aalok ng kakaibang kombinasyon ng tibay, kakayahang umangkop, at pagganap. Ginawa ang mga tubong ito gamit ang mataas na kalidad na haluang metal ng hindi kinakalawang na bakal, kadalasang naglalaman ng chromium, nickel, at iba pang elemento na lumilikha ng isang nakapagpapagaling na protektibong oxide layer. Ang inobatibong komposisyon ng metal na ito ay nagsisiguro ng kahanga-hangang paglaban sa korosyon, oksihenasyon, at pagkasira dahil sa kemikal sa iba't ibang kondisyon ng paggamit. Ginagawa ang mga tubo sa pamamagitan ng mga abansadong proseso kabilang ang seamless drawing o mga teknik sa pagpuputol, na nagreresulta sa mga produkto na nagpapanatili ng integridad ng istraktura sa ilalim ng matinding temperatura at presyon. Ang kanilang makinis na panloob na ibabaw ay nagpapaliit ng pagkalugi sa pamamagitan ng alitan at nagpipigil sa pagtambak ng materyales, kaya't angkop ang mga ito para sa mga aplikasyon sa transportasyon ng likido. Makukuha sa iba't ibang grado, sukat, at kapal ng pader, ang mga hindi kinakalawang na tubo ay gumaganap ng mahalagang papel sa mga industriya mula sa pagproseso ng pagkain at pagmamanupaktura ng gamot hanggang sa mga kemikal na halaman at offshore na instalasyon. Ang kanilang superior na mekanikal na mga katangian, kabilang ang mataas na tensile strength at mahusay na paglaban sa pagkapagod, ay nagsisiguro ng maaasahang pagganap sa parehong mataas na presyon ng sistema at aplikasyon sa vacuum. Ang mga modernong pamamaraan sa pagmamanupaktura ay nagbibigay-daan sa tumpak na kontrol sa dimensyon at pagtatapos ng ibabaw, upang matugunan ang mahigpit na pamantayan ng industriya at mga kinakailangan sa regulasyon.