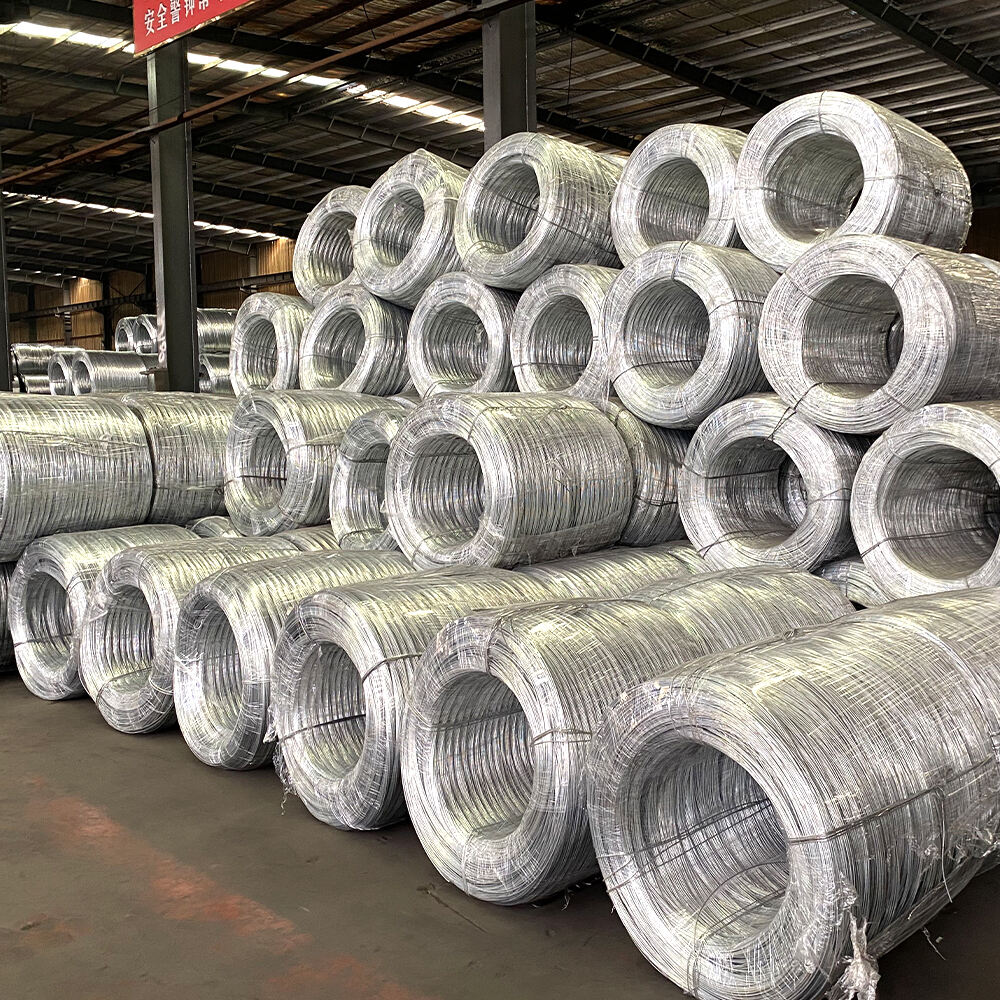

stahldraht

Stahldraht stellt eine grundlegende Komponente in modernen Industrieanwendungen dar, gekennzeichnet durch seine vielseitige Natur und außergewöhnliche mechanische Eigenschaften. Dieses Konstruktionsmaterial besteht aus kaltgezogenen Stahlfäden, das durch einen präzisen Fertigungsprozess hergestellt wird, der seine Festigkeit und Langlebigkeit verbessert. Stahldraht ist in verschiedenen Qualitäten, Durchmessern und Zugfestigkeiten erhältlich, wodurch er an zahlreiche Anwendungen in unterschiedlichen Branchen angepasst werden kann. Der Herstellungsprozess umfasst das Durchziehen von hoch- oder niedrigkohlenstoffhaltigem Stahl durch schrittweise verkleinernde Matrizen, um den gewünschten Durchmesser und die gewünschten mechanischen Eigenschaften zu erreichen. Das Ergebnis ist ein Produkt, das bemerkenswerte Zugfestigkeit mit Flexibilität kombiniert – wesentliche Eigenschaften für seine vielfältigen Anwendungsmöglichkeiten. Moderne Stahldrahtproduktion beinhaltet fortschrittliche Beschichtungstechnologien, einschließlich Verzinkung und Polymerbeschichtung, um Korrosionswiderstandsfähigkeit und Langlebigkeit zu erhöhen. Das Material wird im Bauwesen umfassend eingesetzt, beispielsweise als Bewehrung in Betonkonstruktionen und als Seile für Hängebrücken. In der Automobilindustrie ist Stahldraht entscheidend für die Reifenverstärkung und mechanische Federn. Der Agrarsektor nutzt ihn für Zäune und Ballenpressanwendungen, während sich die Energiewirtschaft auf ihn für Stromübertragungskabel und Offshore-Trossen verlässt.