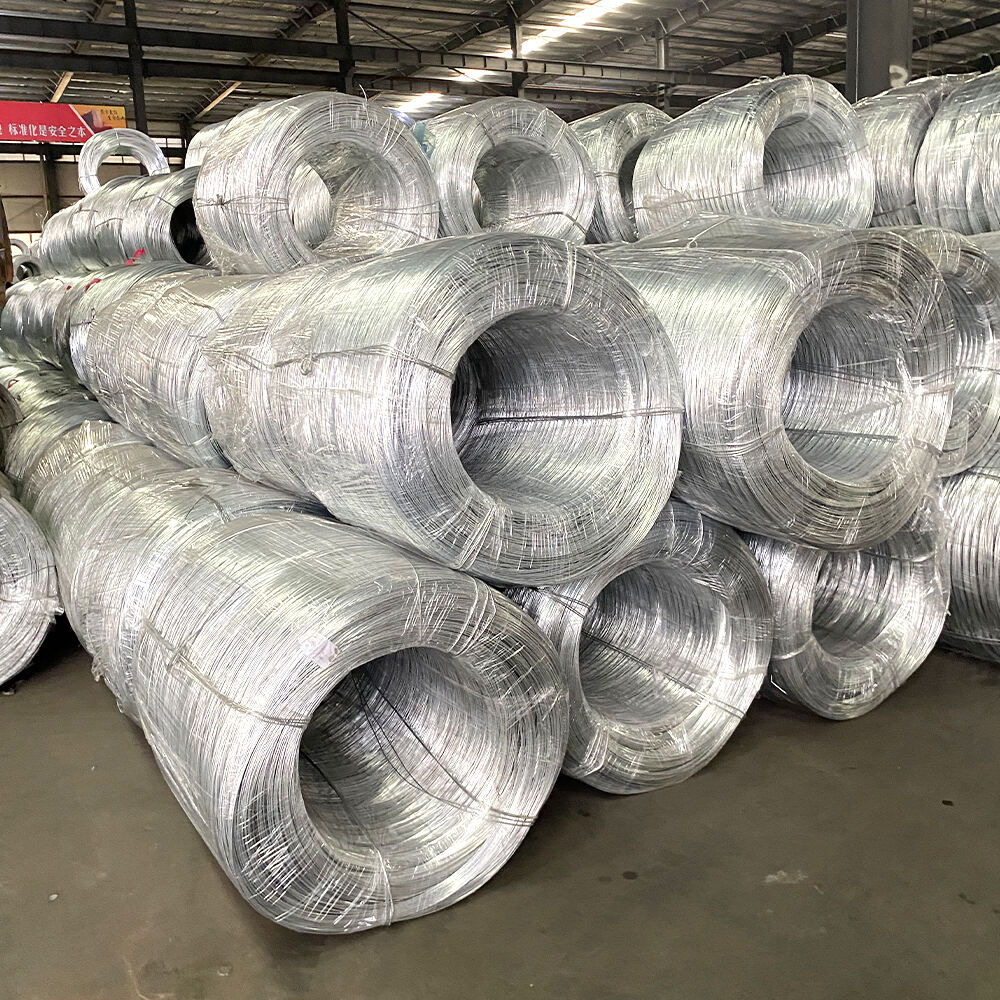

galvanierter Draht

Verzinkter Draht stellt eine entscheidende Innovation in der Metallverarbeitung dar, indem er Langlebigkeit mit vielseitiger Funktionalität kombiniert. Dieser spezielle Draht durchläuft einen ausgeklügelten Verzinkungsprozess, bei dem Stahl- oder Eisendraht mit einer schützenden Zinkbeschichtung überzogen wird, um eine Barriere gegen Korrosion und Rost zu schaffen. Der Prozess umfasst das Tauchen des Drahtes in flüssiges Zink bei Temperaturen von etwa 460 Grad Celsius, wodurch eine vollständige Abdeckung und maximale Schutzwirkung gewährleistet werden. Das resultierende Produkt weist eine außergewöhnliche Widerstandsfähigkeit gegenüber Umwelteinflüssen auf, behält dabei jedoch seine strukturelle Integrität. Moderne verzinkte Drähte sind in verschiedenen Durchmessern und Zugfestigkeiten erhältlich und decken somit unterschiedlichste industrielle und gewerbliche Anwendungen ab. Vom Bauwesen und der Landwirtschaft bis hin zur Fertigung und künstlerischen Gestaltung ist verzinkter Draht ein wesentlicher Bestandteil zahlreicher Branchen. Dank seines hervorragenden Verhältnisses von Stärke zu Gewicht eignet er sich ideal für Zäune, Befestigungen und Konstruktionen zur Stützung. Die Zinkbeschichtung des Drahtes bietet nicht nur Schutz, sondern verfügt auch über selbstheilende Eigenschaften, bei denen geringfügige Kratzer durch den umgebenden Zinkmantel durch einen opfernden Prozess geschützt werden. Dieses fortschrittliche Material entwickelt sich weiter durch Verbesserungen bei Beschichtungstechniken und Legierungs zusammensetzungen und ist daher eine zunehmend wertvolle Ressource in modernen Infrastruktur- und Industrieanwendungen.