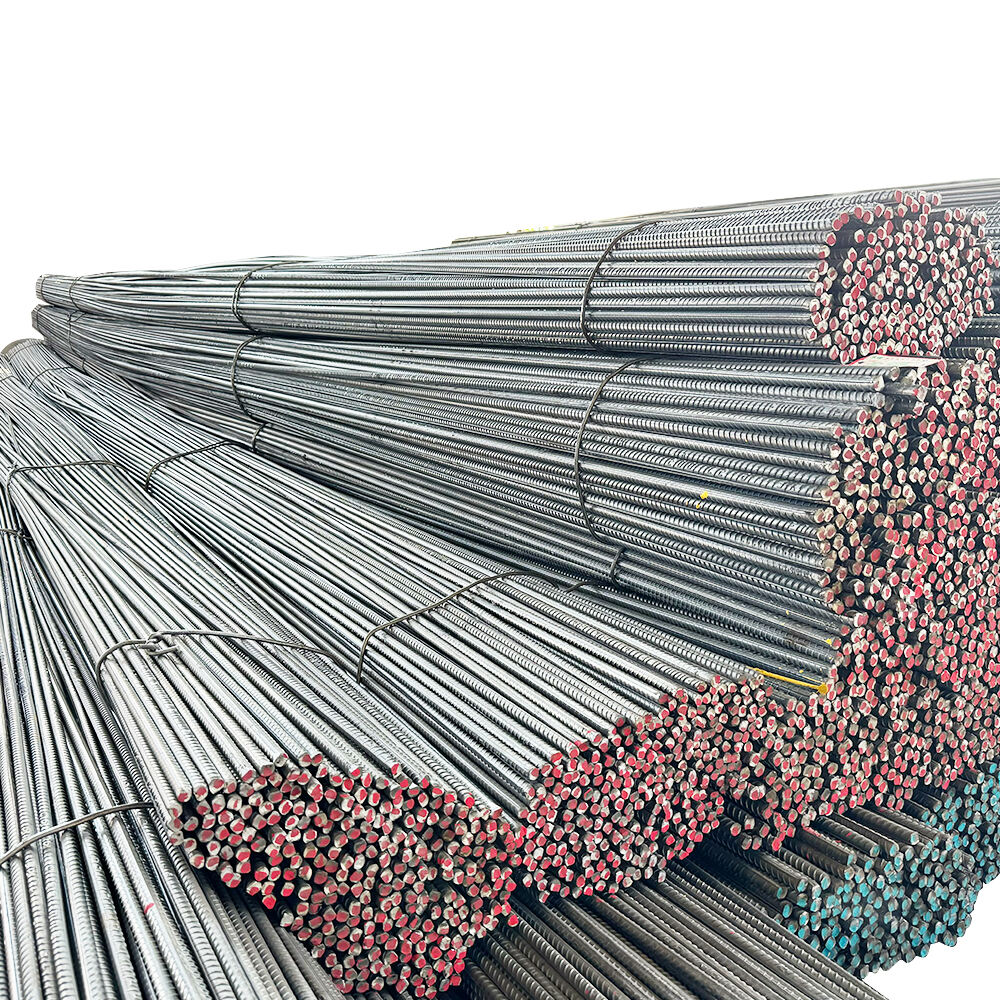

rebar suppliers

Rebar suppliers play a crucial role in the construction industry by providing essential reinforcement materials that ensure structural integrity and durability. These suppliers serve as vital links in the construction supply chain, offering various grades, sizes, and specifications of reinforcement bars to meet diverse project requirements. Modern rebar suppliers leverage advanced inventory management systems and quality control processes to maintain consistent product quality and timely delivery. They typically stock both standard and custom-length rebars, along with complementary products such as wire mesh, stirrups, and tie wire. Many suppliers also offer value-added services such as cutting, bending, and fabrication to exact specifications, reducing on-site labor and improving construction efficiency. Professional rebar suppliers maintain relationships with multiple manufacturers, ensuring competitive pricing and reliable supply chains. They also provide technical consultation, helping customers select the appropriate rebar grade and size for specific applications, while ensuring compliance with local building codes and industry standards.