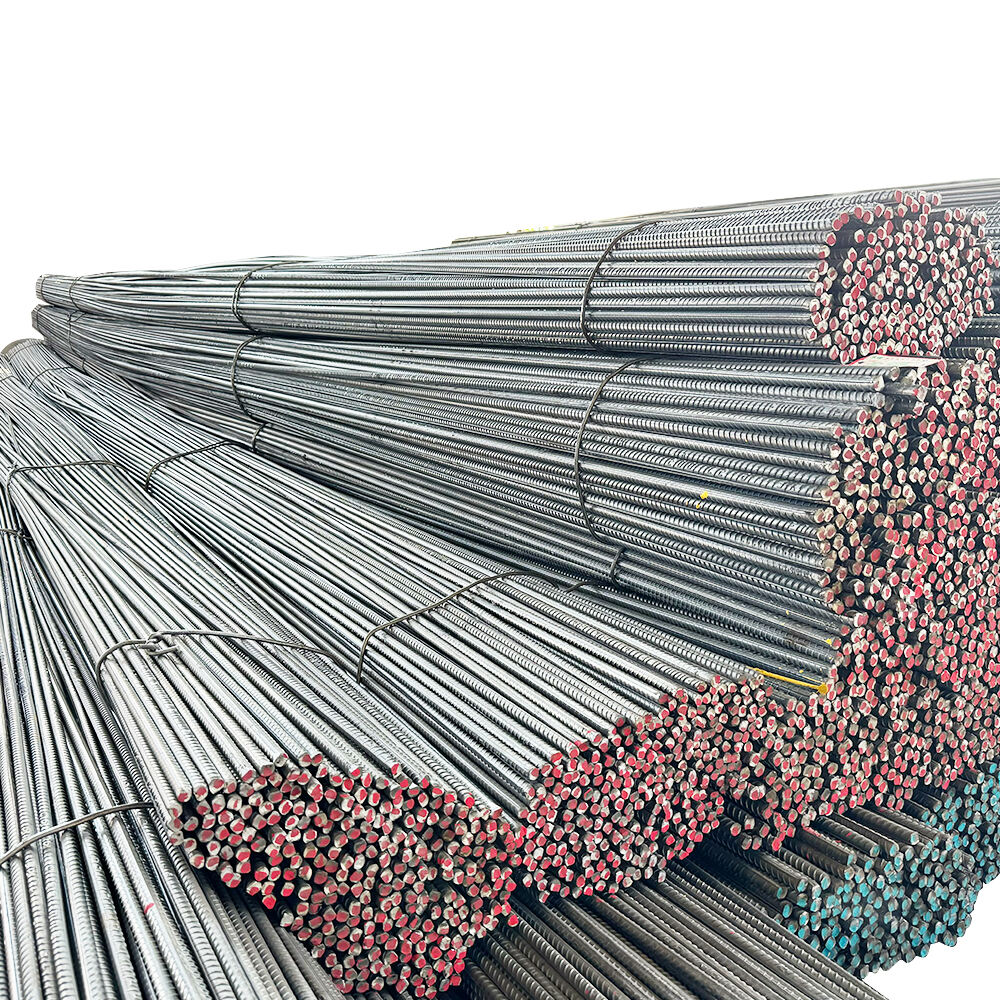

deformed bar

A deformed bar, also known as rebar or reinforcing bar, is a crucial steel reinforcement component widely used in construction and civil engineering projects. These bars feature distinct surface patterns, including ribs, lugs, or deformations that significantly enhance their bonding capabilities with concrete. The strategic placement of these deformations along the bar's length creates a mechanical interlock between the steel and surrounding concrete, resulting in superior structural integrity. Deformed bars are manufactured through a specialized rolling process that ensures consistent quality and precise dimensional accuracy. They are available in various grades, diameters, and lengths to accommodate different construction requirements. The primary function of deformed bars is to provide tensile strength to concrete structures, as concrete alone exhibits poor tensile performance. These bars effectively distribute loads, prevent cracking, and enhance the overall durability of concrete structures. Their applications span across residential, commercial, and infrastructure projects, including foundations, columns, beams, bridges, and highways. Modern deformed bars are also engineered to resist corrosion and feature optimal yield strength properties, making them essential for long-lasting construction projects.