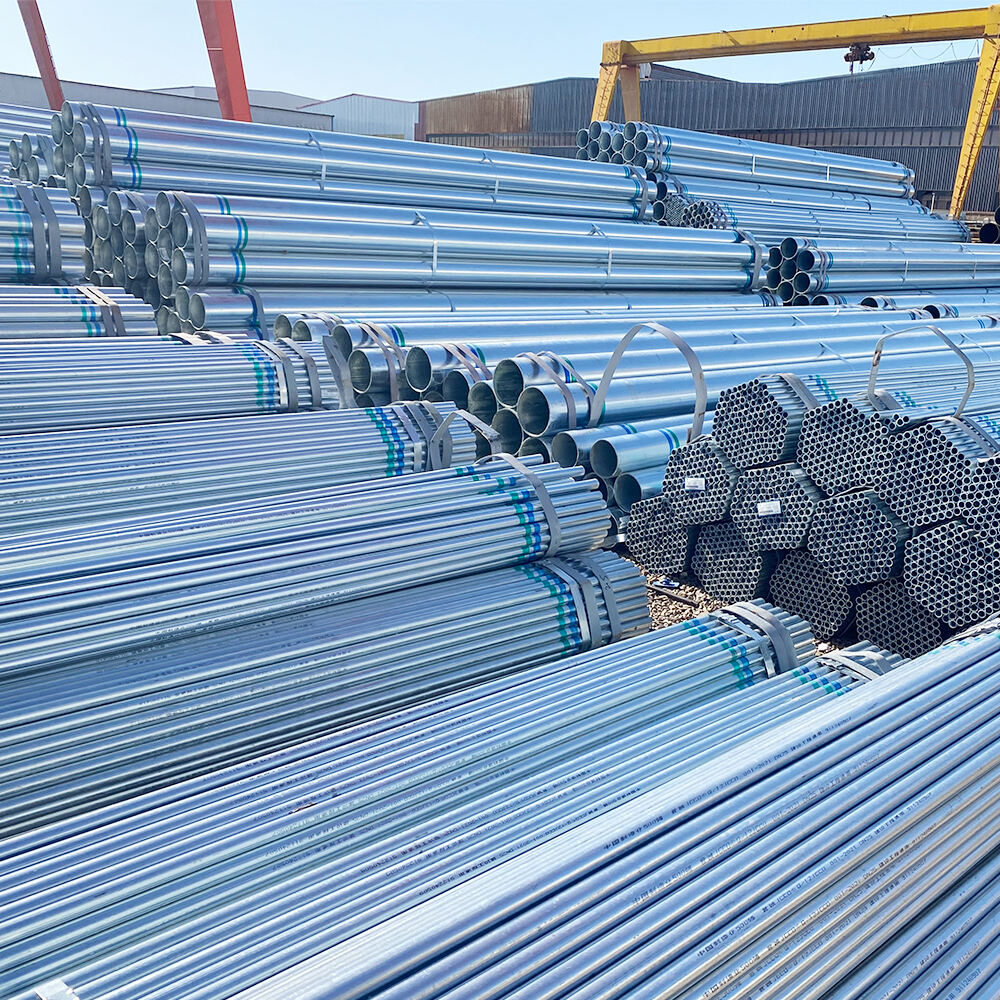

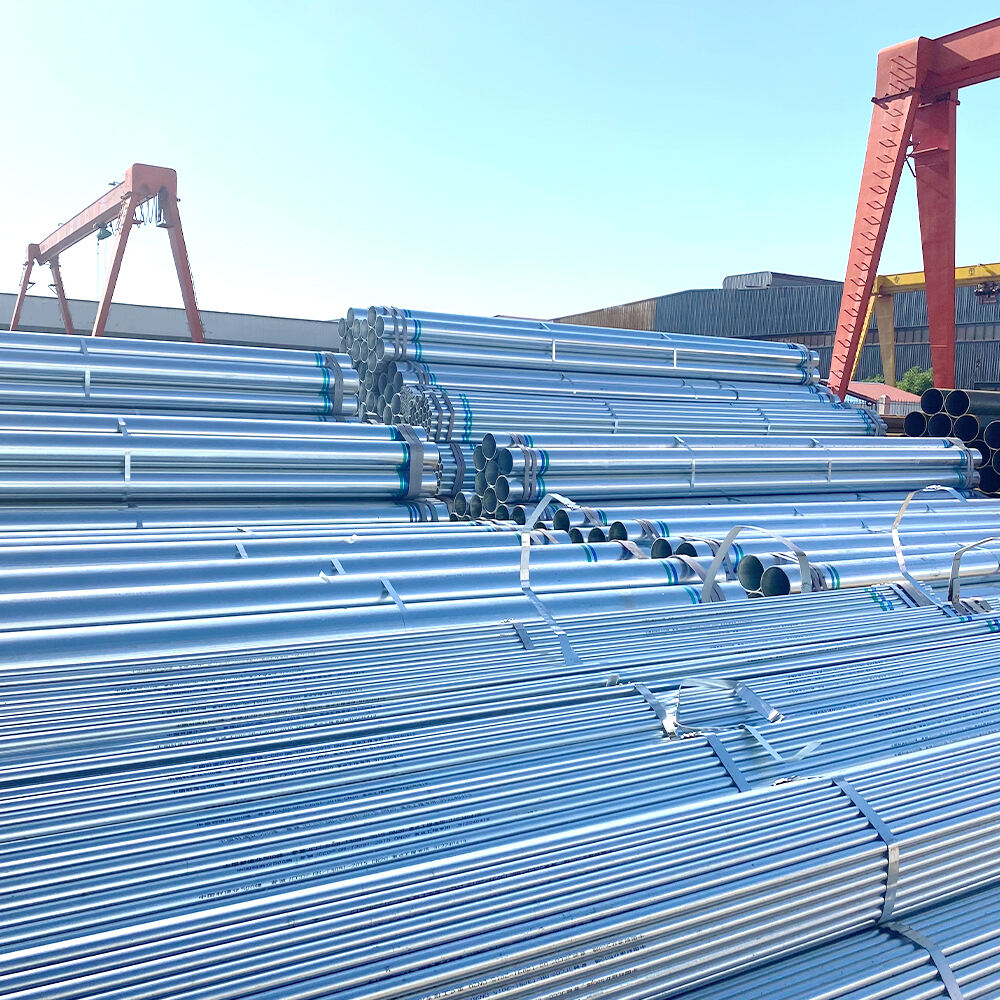

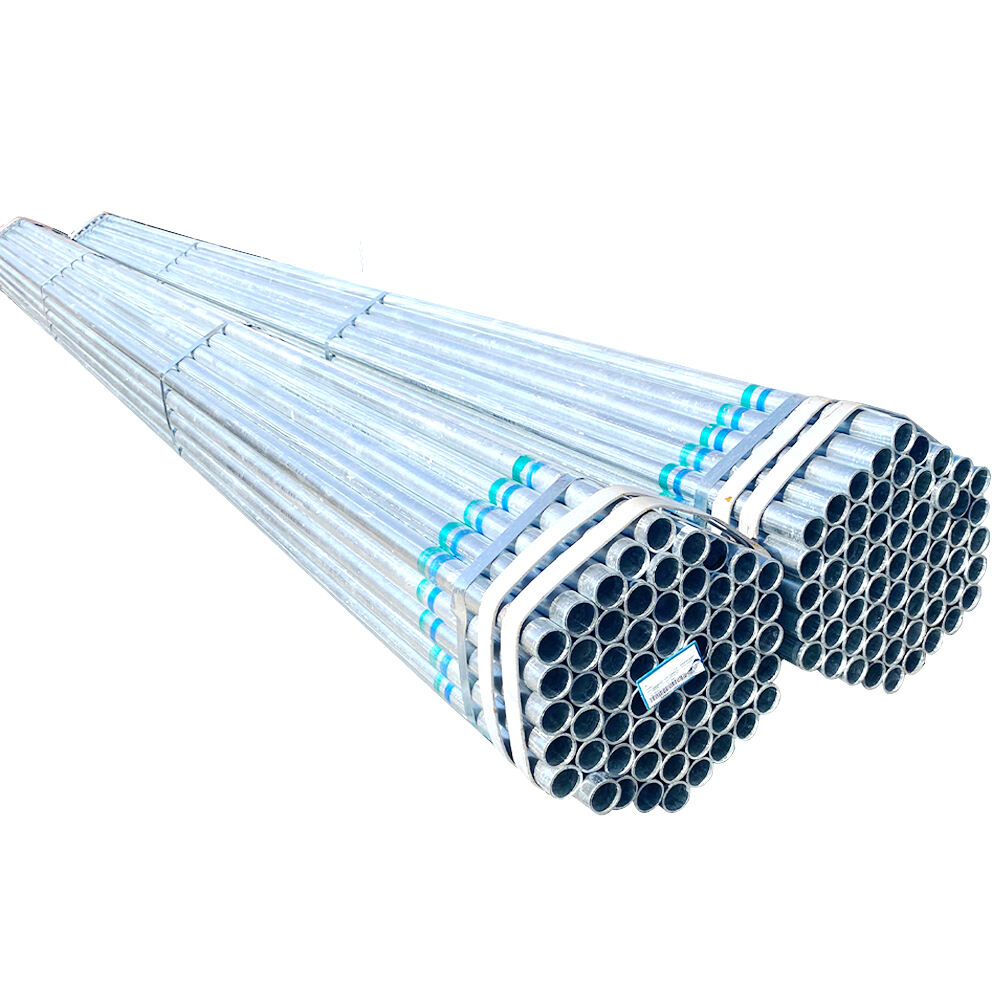

የተሸመነ የብረት ቧንቧ ምንድን ነው

የጂ የተቆዳ ብረት ቅጠል የተሰራው በማይዳለው አካሄድ ሂደት በመቀለጫ ሥር የተሰሩ የብረት ቅጠላት በፅብቅ የዜንክ ውስጥ የሚሰራው ለመጠበቅ ሲሆን ይህ የመታል ብየድ ቅር ሂደት የሚያስከትለው የጂ ብረት ክፍልን ከመበላሸትና ከዝገት የሚጠበቅ ጭብጭብ የተቆዳ አሣሪያ ነው። የጂ ብረት ቅጠላት የተቆዳው ሂደት በተለይ የብረት ቅጠላት የሚታረጉበት፣ በግምታ 860 ዲግሪ ፋረን ሃይት (460 ዲግሪ ሴንቲ ግሬድ) የሚሆንበት የዜንክ ሙቀት ውስጥ የሚገለበጡበት እና የሚታረጉበት ሲሆን ይህ የሚፈጥረው የተለያዩ መስኮች አቅጣጫ ያላቸው የዜንክ አሣሪያ ነው። ይህ ቅጠላት በተለያዩ ስፋቶችና የቁሳቁስ ጠንካራነት ይገኛሉ ለተለያዩ የኢንዱስትሪ እና የንግድ ጥቅሞች ለማሟላት። የዜንክ አሣሪያው እንደ የመቀበሪያ አሣሪያ ይሰራል፣ ማለት ይህ አሣሪያ በመበላሸት የመሬቱን ብረት ይጠበቃል እና የቅጠላውን ጥራት ይጨርሻል። የጂ ብረት ቅጠላት በውሃ የመላው ስርዓቶች፣ የእሳት ስፕሪንክለር ስርዓቶች፣ የመዋቅር አገልግሎቶች እና በተለያዩ የኢንዱስትሪ ሂደቶች ውስጥ ትልቅ ጥቅም አላቸው። በተለይ በአካባቢዎች ውስጥ የሚገኙ ነገሮች የሚያስፈልጉት ጥቅም ላይ ይውላሉ ለምሳሌ በሙቀት የተጠበቀው የዜንክ አሣሪያ የአየር መበላሸት ለመቸግር በጣም ጥሩ ነው። የተደራጀው የማምረት ሂደት በተለያዩ ጥቅሞች ላይ ትክክለኛ ጥራት እና የተረliable ትምክህ ያረጋግጣል ስለዚህ የጂ ብረት ቅጠላት በመገን እና በኢንዱስትሪ ህንጻዎች ውስጥ የተወሰነ የተጠበቀ መርጫ ናቸው።