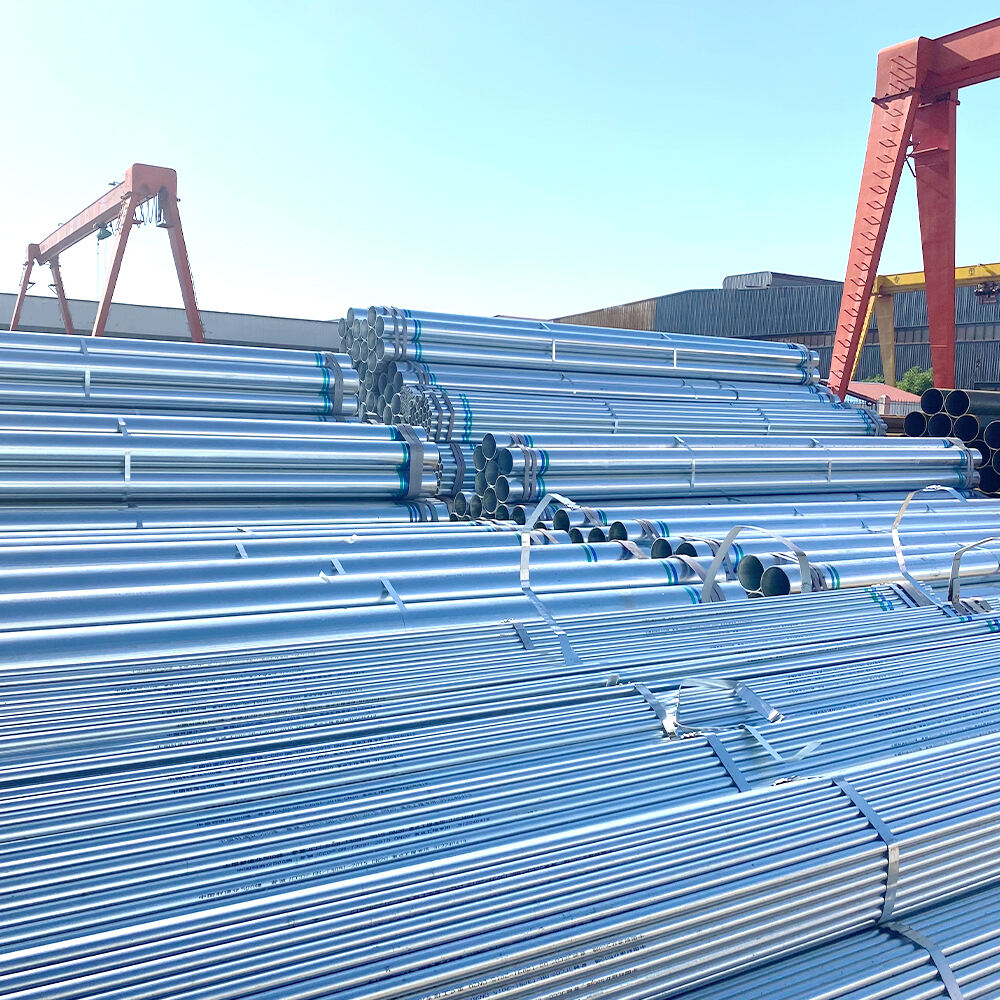

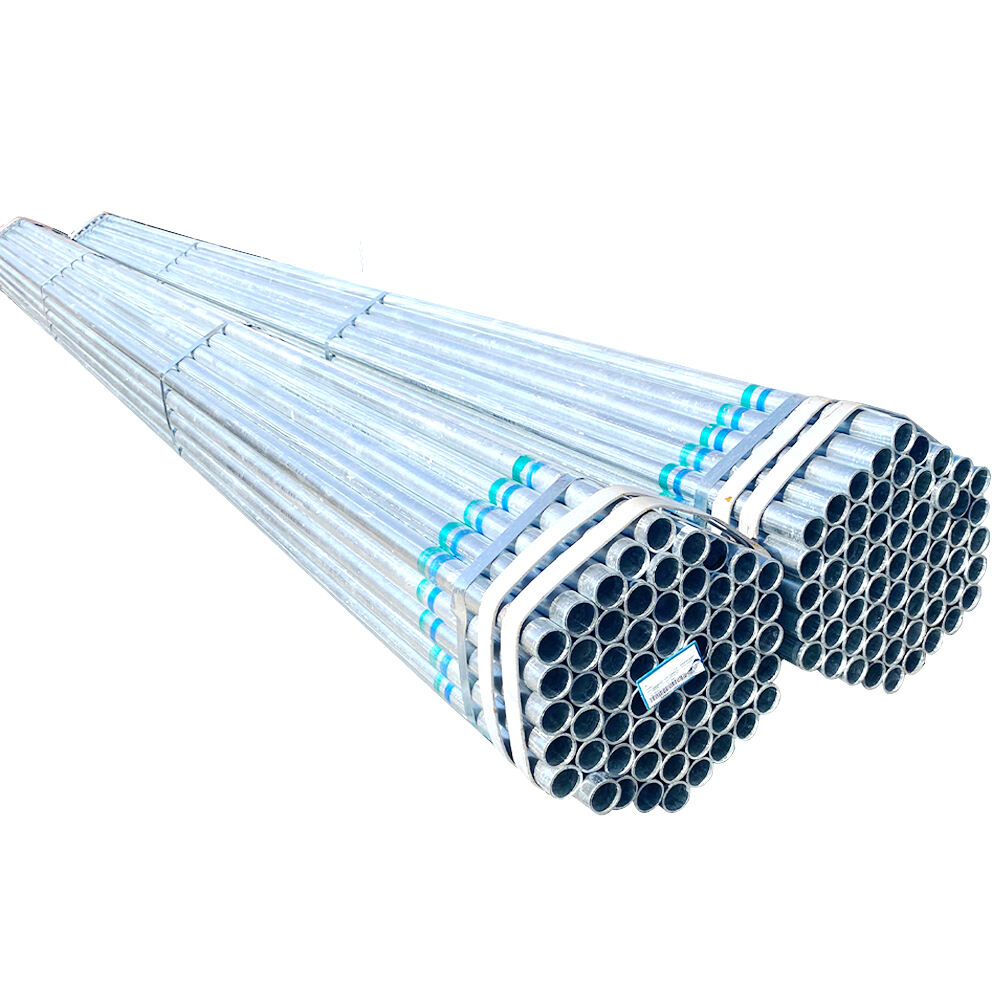

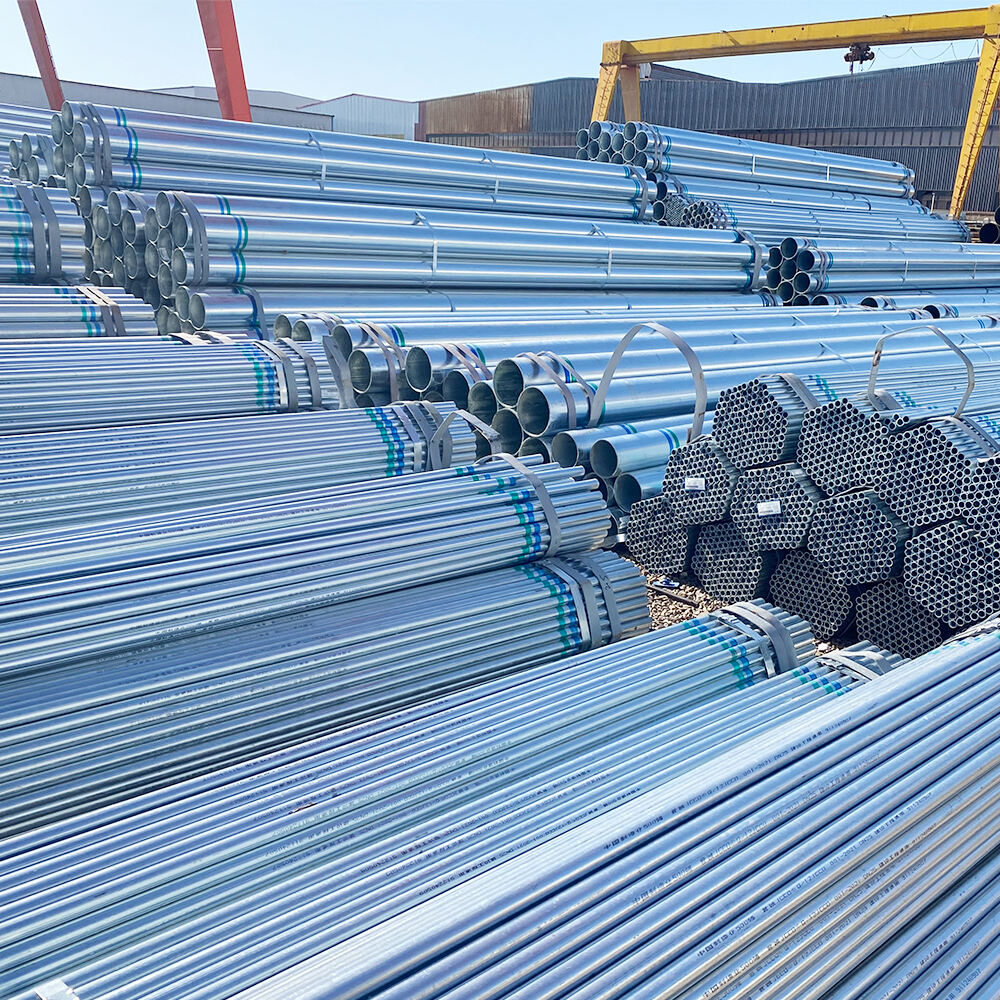

የተሸመነ የብረት ቱቦ

የጂፓ የተሸፈነ ብርንቆል ቅጭሎች በአሁኑ የሥራ እና የኢንዱስትሪ አፕሊኬሽኖች ውስጥ አስፈላጊ አካል ናቸው፣ የመጨረሻውን የዝነብ ቅርፅ በማቅረብ በማይታወቅበት መጠን የሚከላከሉት። ይህ ቅጭሎች በሙሉ የተለየ ሙቀት ያለው የጂፓ ሂደት ሂደት ውስጥ ይሄዳሉ ሲል የብረት ወይም የብረት ቅጭሎች በግማሽ የጂፓ ውስጥ በተወሰነ ሙቀት ላይ (በተቃራኒው 860°F (460°C) ውስጥ ይገለሉ ሲሆን ይህም የመታል ተያያዥ አሣራር ያመነጫል የመሬቱን ብረት ከአካባቢ ጋር በማጭበርበር የሚከላከለው። የሚጠቀሰው የጂፓ አሣራር በተጨማሪ የባህር ጥበቃ እና የቅርብ ጥበቃ ይሰጣል፣ ማለት የጂፓው በመጀመሪያ ይበላሻል ማለት የሚያስፈልገውን ብረት ይጠበቃል። ይህ ቅጭሎች በውሃ የመላክ ስርዓቶች፣ የመዋቅር ድጋፍ፣ የኤሌክትሪክ በር፣ እና በርካታ የኢንዱስትሪ አፕሊኬሽኖች ውስጥ በስፋት ጥቅም ላይ ይመጣሉ። የጂፓ ሂደቱ በደንብ የተገናኘ እና የተያያዘ አሣራር ይፍጠራል እነዚህ የተለያዩ ቅጭሎች በተለመደ 20-25 ዓመታት ድረስ ይቆያሉ በተለመደ በተለያዩ አካባቢዎች ውስጥ፣ ይህም የብረቱ ቅጭል የአገር ሕይወት ይዘት ይጨርሳል። የአሣራሩ ጠንካራነት በተወሰነ ጥያቄዎች መሰረት ሊቀየር ይችላል፣ በተለመደ ከ45 ወይም 100 ሚክሮን መካከል ይገኛል። የአዲስ ጂፓ ቅጭሎች በተጨማሪ የላቀ የላይኛው ጠርዞች ጥራት፣ የትክክለኛ መጠኖች ትክክለኛነት፣ እና የላቀ የወልዲንግ ችሎታ ይሰጣሉ፣ ይህም ለውስጥ እና ለውጭ አፕሊኬሽኖች ተስማሚ ያደርገዋል።