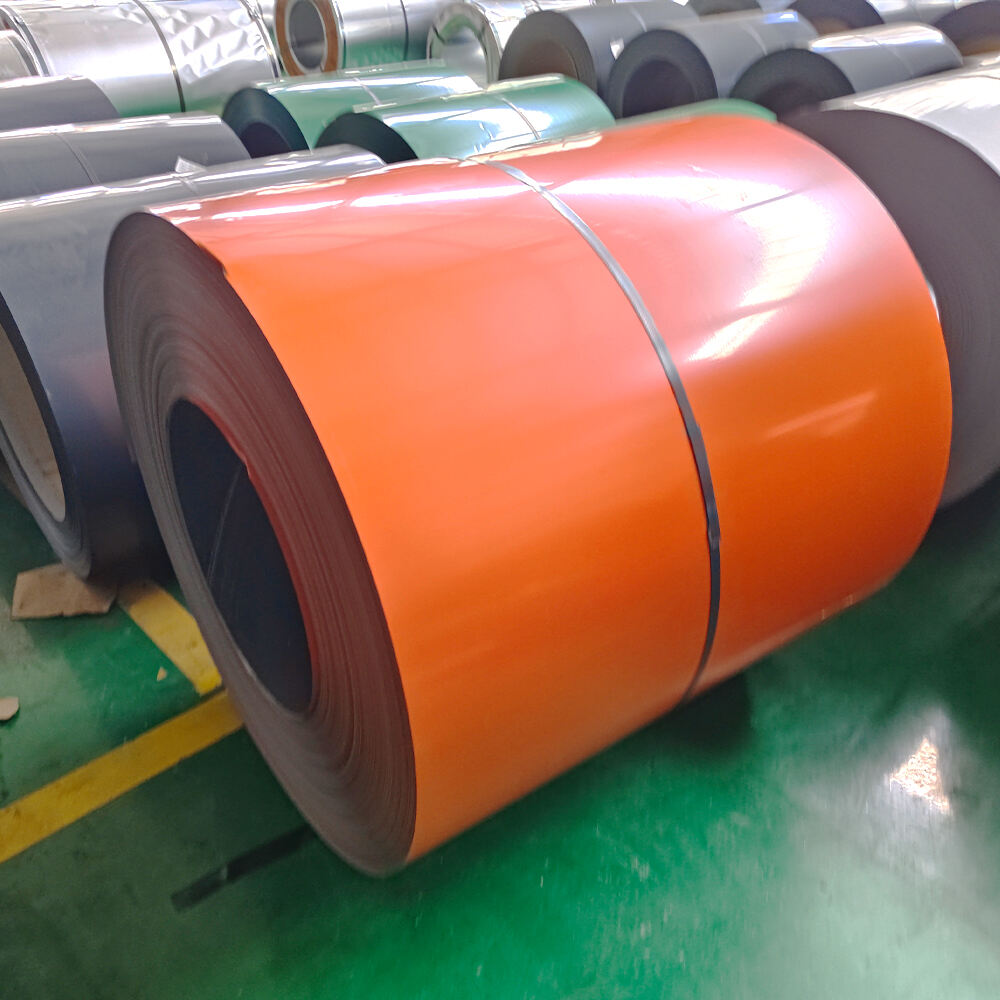

ppgi çelik bobin

PPGI çelik bobin, aynı zamanda Pre-painted Galvanizli Sac bobin olarak bilinir ve inşaat ve imalat malzemelerinde önemli bir gelişmedir. Bu inovatif ürün, sıcak daldırmalı galvanizleme işlemine tabi tutulan bir çelik çekirdekten oluşur, ardından özel bir ön boyama sürecinden geçer. Temel metal, galvanizleme yoluyla çinko kaplama alır ve korozyona karşı sağlam bir bariyer oluşturur. Yüzey daha sonra astar tabakası ve yüksek kaliteli boya ile son katman olmak üzere çeşitli koruyucu katmanlarla kaplanır. Bu sofistike üretim süreci, yapısal dayanıklılık ile estetik görünümü birleştiren çok yönlü bir malzeme ortaya çıkarır. Kaplama sistemi genellikle ön işlem tabakası, astar ve yüzey boyasından oluşur ve her biri çelik alt tabakayı koruyerek özelliklerini artırmak için belirli fonksiyonlara sahiptir. PPGI çelik bobinler çeşitli kalınlıklarda, genişliklerde ve renk seçeneklerinde sunulur, bu da onları farklı uygulamalara uygun kılar. Bu bobinler çatı sistemlerinde, duvar kaplamalarında, otomotiv parçalarında, ev aletlerinde ve endüstriyel ekipmanlarda yaygın olarak kullanılmaktadır. Malzemenin dayanıklılığı, UV radyasyonuna, kimyasal etkilere ve mekanik streslere karşı direnci sayesinde artırılmıştır ve bu da geleneksel çelik ürünlerle karşılaştırıldığında daha uzun kullanım ömrü sağlar.