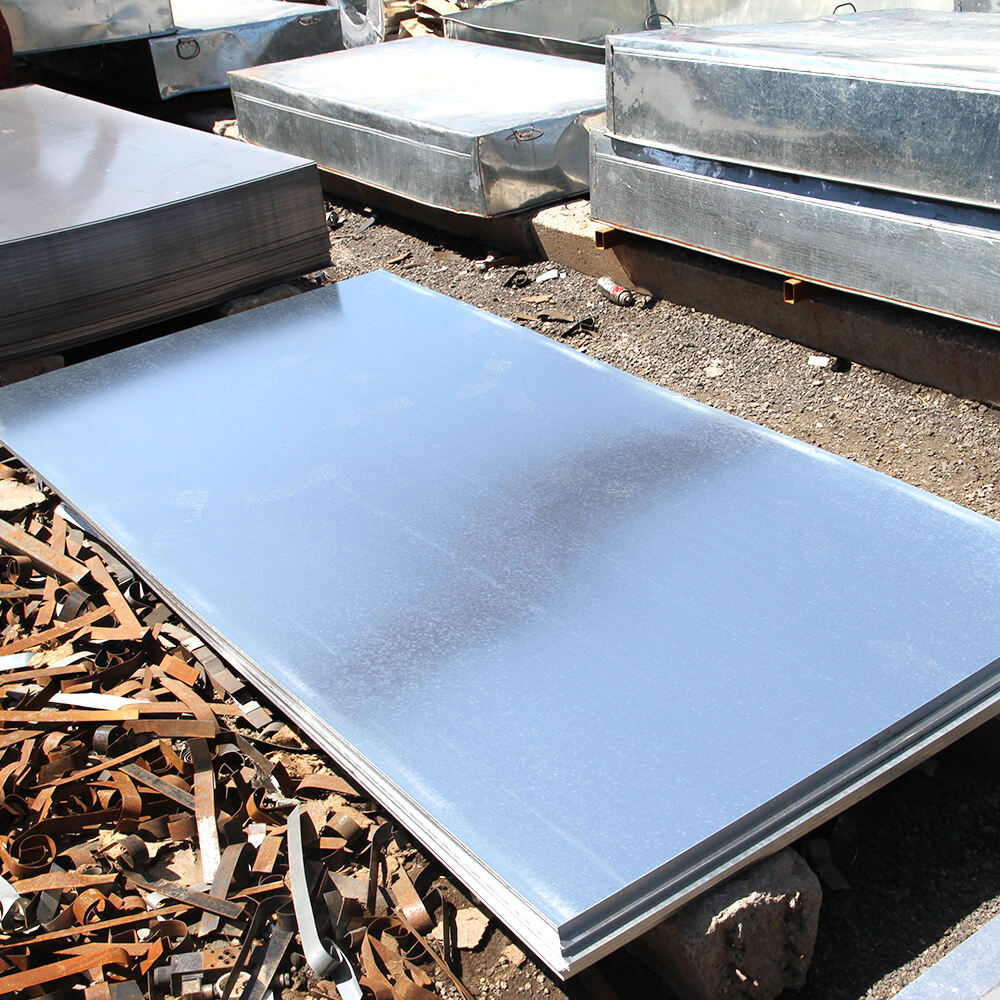

galvanizli çelik levha fiyatı

Galvanizli çelik sac fiyatı, koruyucu çinko kaplama ile işlenmiş çelik sacın maliyetini yansıtan, inşaat ve imalat endüstrilerinde kritik bir faktördür. Bu temel yapı malzemesi, dayanıklılık ile maliyet etkinliğini bir araya getirerek çeşitli uygulamalarda yaygın bir tercih haline gelmiştir. Fiyat genellikle, sac kalınlığı, kaplama kalitesi, pazar talebi ve hammadde maliyetleri gibi faktörlere bağlı olarak değişiklik gösterir. Modern galvanizasyon teknolojisi, sıcak daldırmalı galvanizleme ya da elektrokaplama süreçleri aracılığıyla üstün korozyon direnci sağlayarak malzemenin ömrünü önemli ölçüde uzatır. Bu sacalar, çatı kaplama, otomotiv parçaları, beyaz eşya üretimi ve altyapı projelerinde yaygın olarak kullanılmaktadır. Fiyatlandırma yapısı genelde ham çelik maliyeti, çinko kaplama kalınlığı, işleme ücretleri ve piyasa koşullarını dikkate alır. Galvanizli çelik sac fiyatlamasını anlamak, proje planlaması ve bütçe yönetimi açısından hayati öneme sahiptir çünkü bu maliyetler genel inşaat ve imalat giderlerini doğrudan etkiler. Güncel piyasa, küresel çelik üretimi, çinko arzı ve taşıma maliyetleriyle şekillenen dinamik fiyatlandırma modelleri sergilemektedir. Üreticiler, farklı fiyat seviyelerine ve uygulama gereksinimlerine hitap edecek çeşitli kalite ve spesifikasyonlarda ürün sunarak müşterilerin maliyet ile performans ihtiyaçları arasında denge kurmalarına olanak tanır.