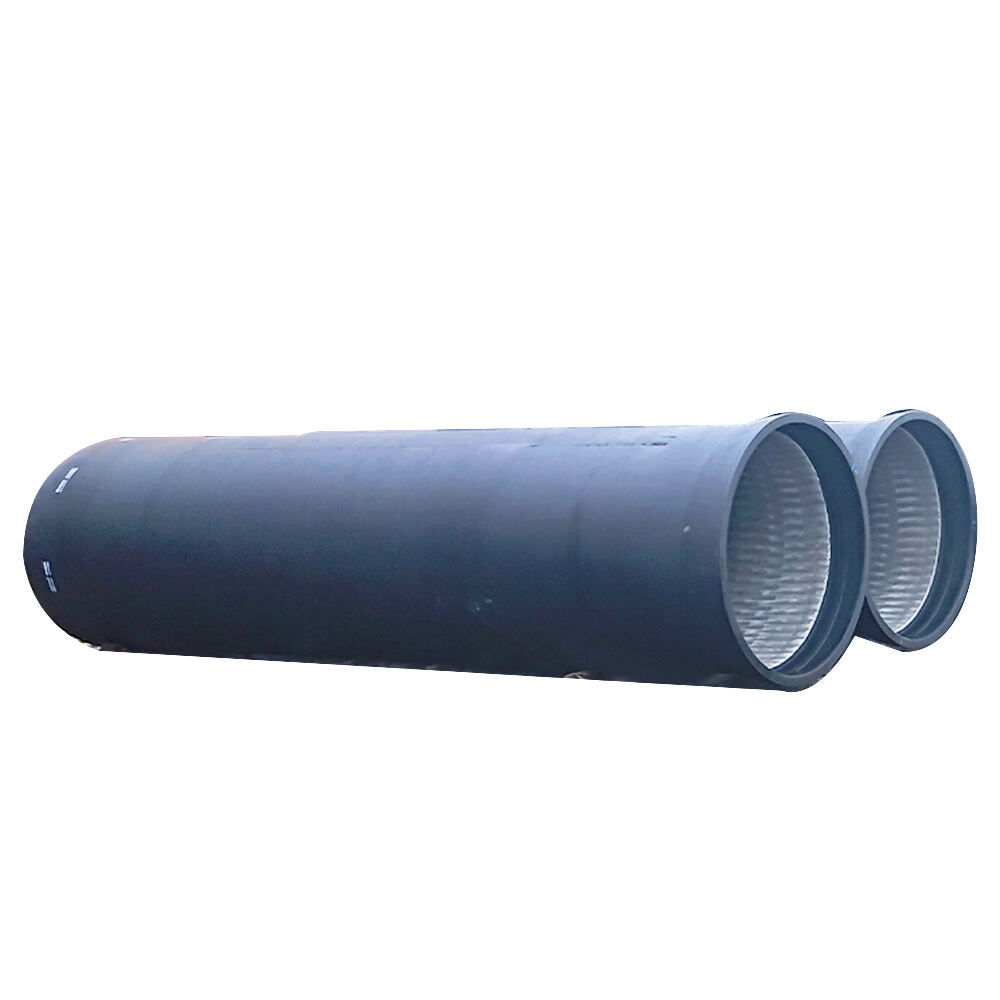

dökme demir boru hattı

Dövme dökme boru sistemi, dayanıklılık ile üstün mekanik özelliklerin birleşimiyle, su ve kanalizasyon altyapısında devrim niteliğinde bir gelişmedir. Bu modern boru sistemi, ergimiş demire magnezyum ekleyen yenilikçi bir metalürji süreciyle üretilmektedir ve bu süreç, olağanüstü mukavemet ve esneklik gösteren bir malzeme ortaya çıkarmaktadır. Dövme dökmede yer alan grafit, pulcuklar yerine küresel nodüller şeklinde oluşur ve bu yapı, çatlamaya karşı direnç gösterir ve aşırı basınç koşullarına dayanıklılık sağlar. Bu borular, 350 ila 400 PSI aralığındaki basınçları taşıyacak şekilde tasarlanmıştır ve bu özellikleriyle hem su dağıtım hem de atık yönetimi sistemleri için idealdir. Dövme dökmenin doğuştan gelen korozyon direnci, koruyucu kaplamalar ve astarlarla artırılarak kullanım ömrü çoğu zaman 100 yılı aşmaktadır. Dövme dökme borular 3 ila 64 inç aralığındaki çaplarda temin edilebilir ve çeşitli debi gereksinimlerine ve kurulum senaryolarına uyum sağlar. Esnek yapısı, hem yer üstünde hem de yer altında uygulamalara olanak tanırken, sağlam yapısı sayesinde özellikle toprak hareketlerinin ya da depremselliğin görüldüğü bölgelerde kullanım için son derece uygundur. Sistemdeki eklem tasarımları, itme usulü, mekanik ve sabitlenmiş seçenekleri içererek kurulum ve bakım işlemlerinde esneklik sağlamaktadır.