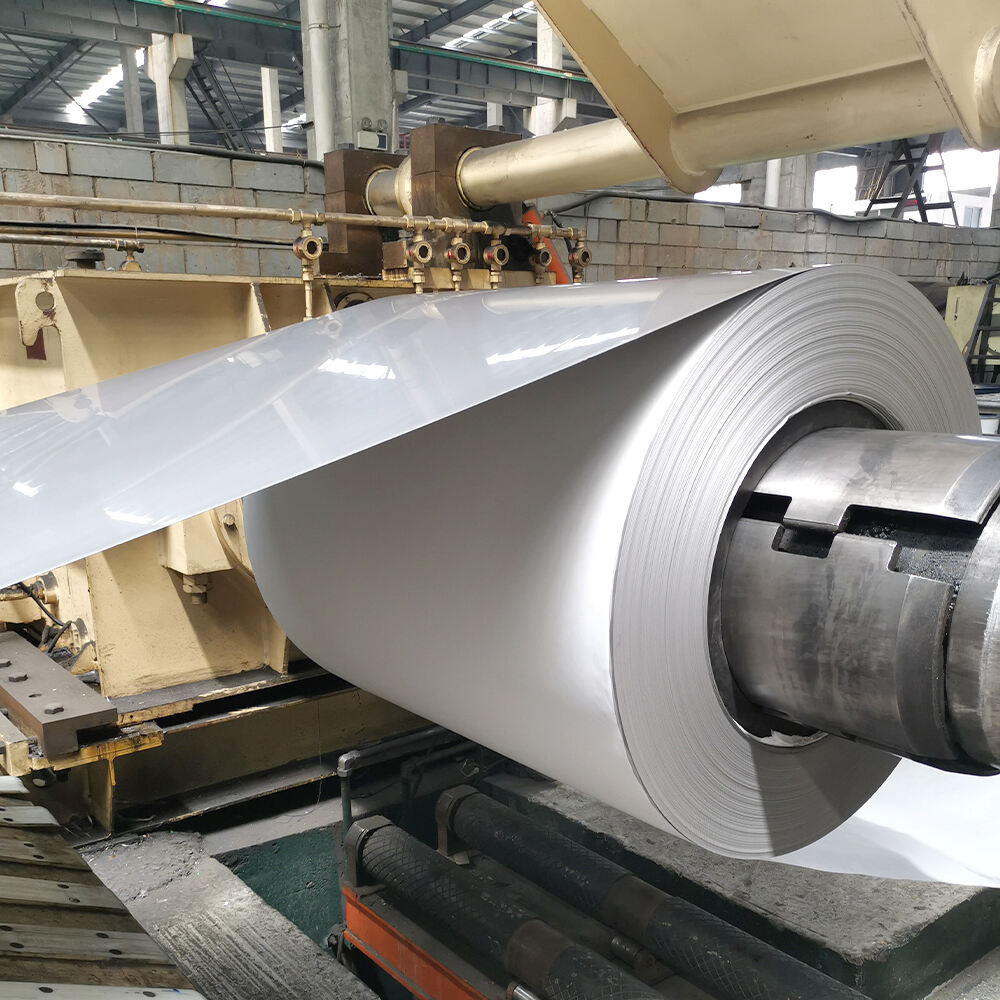

hindi kinakalawang na bakal na mainit na pinagsama-samang coil

Ang stainless steel hot rolled coil ay kumakatawan sa isang pangunahing materyales sa modernong pagmamanupaktura, na kilala sa kahanga-hangang tibay at sari-saring gamit. Ginagawa ang produktong ito sa pamamagitan ng isang mahusay na proseso ng metalurhiya kung saan pinainit ang stainless steel sa itaas ng kanyang recrystallization temperature at dinadaan sa isang serye ng mga roller. Ang resultang materyales ay mayroong higit na mga mekanikal na katangian, kabilang ang pinahusay na lakas, mahusay na paglaban sa korosyon, at kapansin-pansing formability. Ang proseso ng hot rolling ay nagsisiguro ng pantay na distribusyon ng kapal at pinakamahusay na istraktura ng butil, na nagpapagawa itong perpekto para sa iba't ibang aplikasyon sa industriya. Ang mga coil na ito ay may iba't ibang grado at espesipikasyon, kadalasang kinabibilangan ng austenitic, ferritic, at martensitic na mga uri, na bawat isa ay angkop para sa tiyak na mga aplikasyon. Ang likas na mga katangian ng materyales ay nagpapahalaga nang malaki sa konstruksyon, pagmamanupaktura ng sasakyan, produksyon ng mabigat na kagamitan, at arkitekturang aplikasyon. Ang kanyang kakayahang mapanatili ang istruktural na integridad sa ilalim ng matinding kondisyon, kasama ang kanyang aesthetic appeal, ay nagwagi sa kanya bilang paboritong pagpipilian sa parehong industriyal at komersyal na sektor. Ang proseso ng pagmamanupaktura ay nagpapahintulot din ng pagpapasadya sa mga tuntunin ng kapal, lapad, at surface finish, na nagbibigay-daan sa mga tagagawa na matugunan ang magkakaibang specification ng mga kliyente at pamantayan ng industriya.