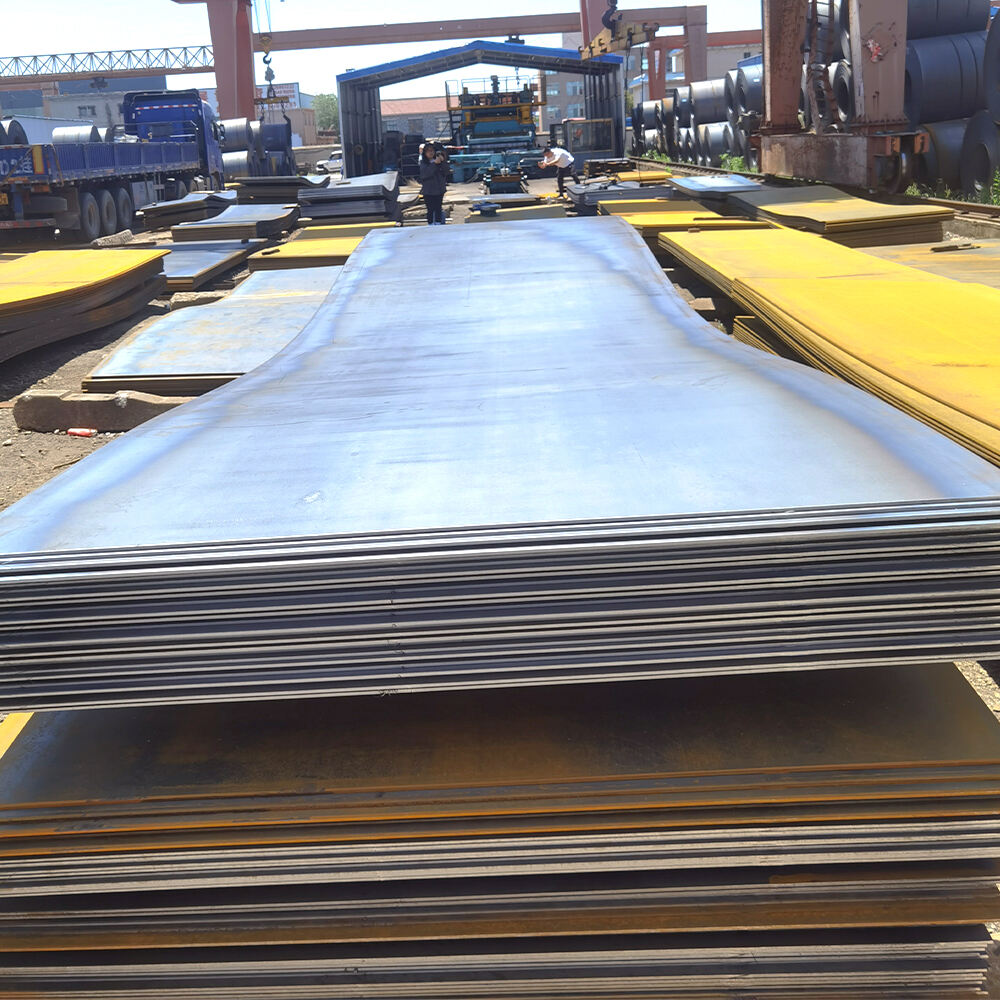

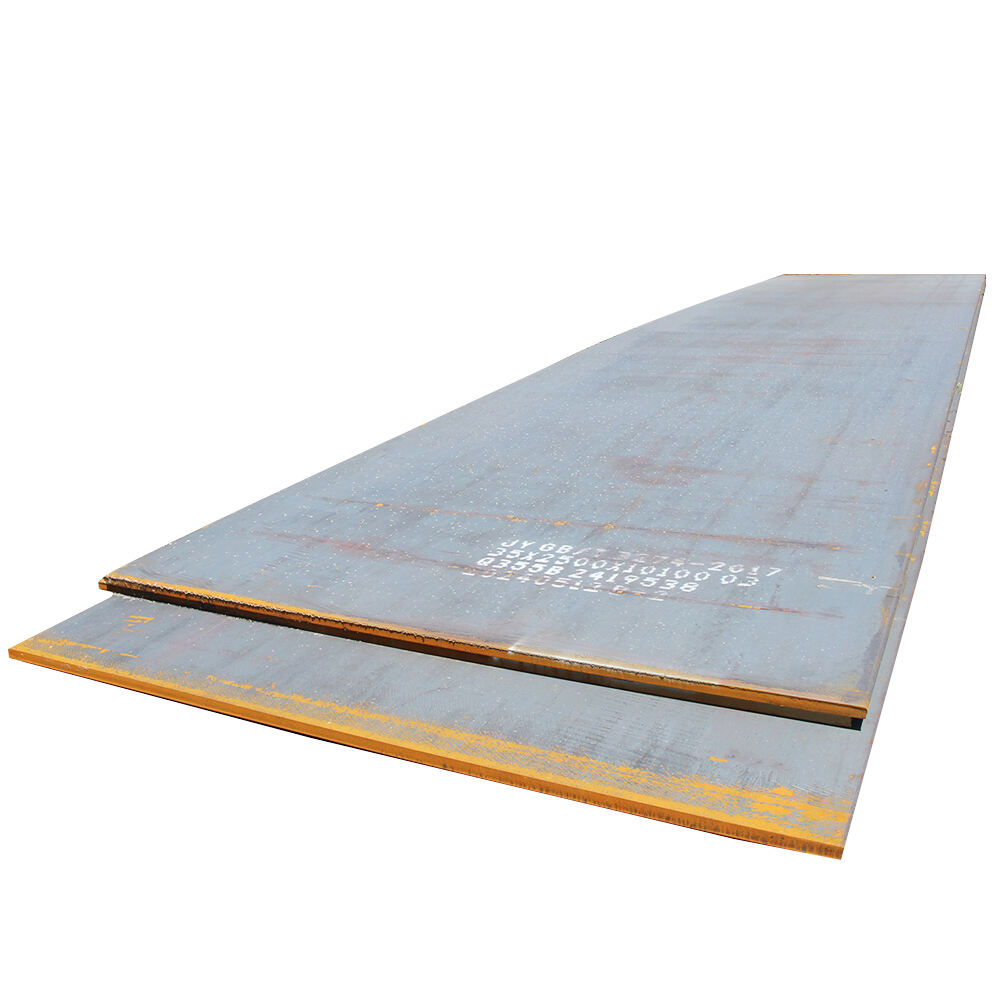

mataas na carbon na bakal na sheet metal

Ang mataas na asero na may karbon ay isang matibay at maraming gamit na materyales na kilala sa kahanga-hangang lakas at tibay nito. May karbon na karaniwang nasa pagitan ng 0.60% at 1.00%, ang materyales na ito ay may mas mataas na kahirapan at lumalaban sa pagsusuot kumpara sa mga aserong may mas mababang karbon. Ang proseso ng paggawa ay nagsasangkot ng maingat na kontrol sa temperatura at tumpak na pagbuburo ng alloy upang makamit ang pinakamahusay na mekanikal na katangian. Ang mga sheet na ito ay idinisenyo upang mapanatili ang integridad ng istraktura sa ilalim ng matinding kondisyon, kaya mainam ito para sa mabibigat na industriyal na aplikasyon. Ang natatanging komposisyon ng materyales ay nagbibigay ng mahusay na kakayahang maproseso habang pinapanatili ang mataas na tensile strength at lumalaban sa pagbaluktot. Ang mga modernong teknik sa produksyon ay nagsisiguro ng pare-parehong kalidad sa lahat ng sheet, na may iba't ibang pagpipilian ng kapal upang matugunan ang tiyak na mga pangangailangan. Maaaring i-customize ang surface finish para umangkop sa iba't ibang aplikasyon, mula sa makinis hanggang sa may tekstura, at maaaring karagdagang gamutin ang materyales sa pamamagitan ng pagproseso ng init upang mapahusay ang tiyak na mga katangian. Maraming industriya ang umaasa sa mataas na asero na may karbon para sa mga aplikasyon na nangangailangan ng hindi kapani-paniwalang lumalaban sa pagsusuot, pagpapanatili ng lakas sa mataas na temperatura, at pangmatagalang katiyakan. Ang likas na katangian ng materyales ay nagpapahusay dito sa paggawa ng mga tool na pamputol, mga bahagi ng industriyal na makinarya, at mga istraktural na elemento na nakakaranas ng mataas na presyon.