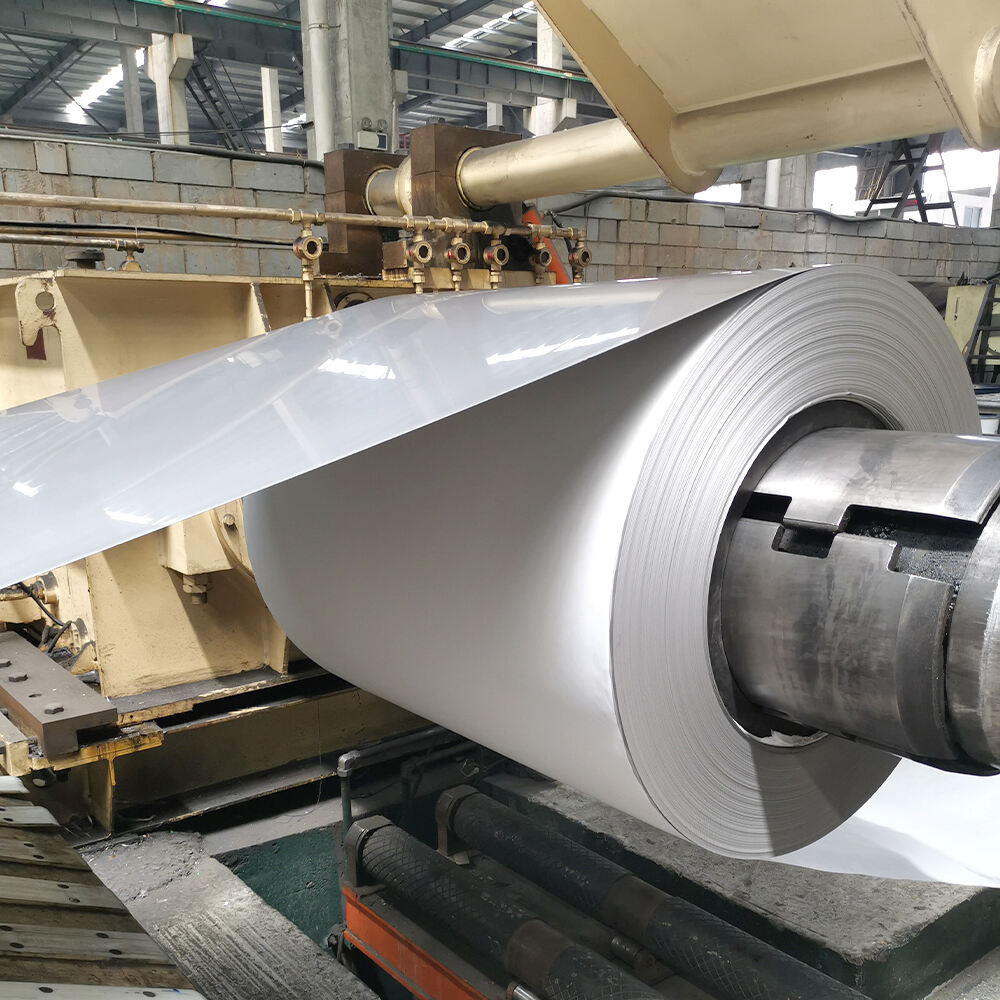

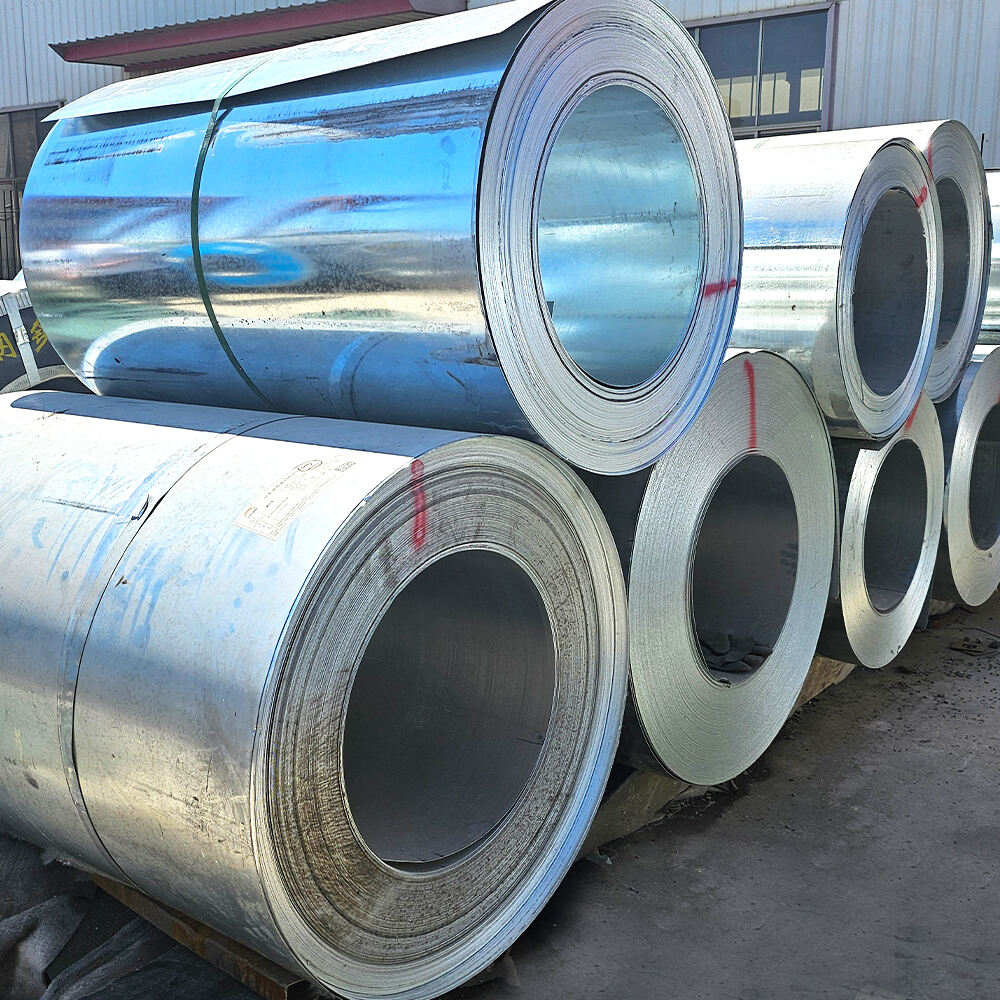

carbon steel coil para sa pagbebenta

Ang carbon steel coil ay kumakatawan sa isang maraming gamit at mahalagang materyales sa modernong pagmamanupaktura, na nag-aalok ng kahanga-hangang lakas at tibay para sa iba't ibang aplikasyon sa industriya. Ang mga coil na ito ay ginawa nang tumpak sa pamamagitan ng isang paunlaran na proseso ng pag-roll na nagsisiguro ng pare-parehong kapal at mataas na kalidad ng ibabaw. Ang komposisyon ng materyales ay karaniwang binubuo ng iron na may carbon content na nasa pagitan ng 0.04% hanggang 2.0%, na nagbibigay ng optimal na mekanikal na katangian para sa iba't ibang pangangailangan sa pagmamanupaktura. Ang mga coil na ito ay available sa iba't ibang grado, kapal, at lapad upang tugunan ang iba't ibang pangangailangan ng industriya, mula sa pagmamanupaktura ng sasakyan hanggang sa mga aplikasyon sa konstruksyon. Ang proseso ng pagmamanupaktura ay kasama ang maingat na kontrol sa temperatura at tumpak na teknik sa pag-roll upang makamit ang ninanais na mekanikal na katangian, kabilang ang tensile strength, ductility, at kahirapan. Ang mga modernong paraan ng produksyon ay nagsasama ng paunlaran ng kontrol sa kalidad, na nagsisiguro na ang bawat coil ay sumusunod sa mahigpit na pamantayan ng industriya para sa dimensional accuracy at kalidad ng ibabaw. Ang mga coil ay dumaan sa masusing pagsusuri para sa mekanikal na katangian, komposisyon ng kemikal, at kalidad ng ibabaw bago aprubahan para sa pagbebenta, na nagsisiguro ng katiyakan at pagkakapareho sa mga aplikasyon nito.