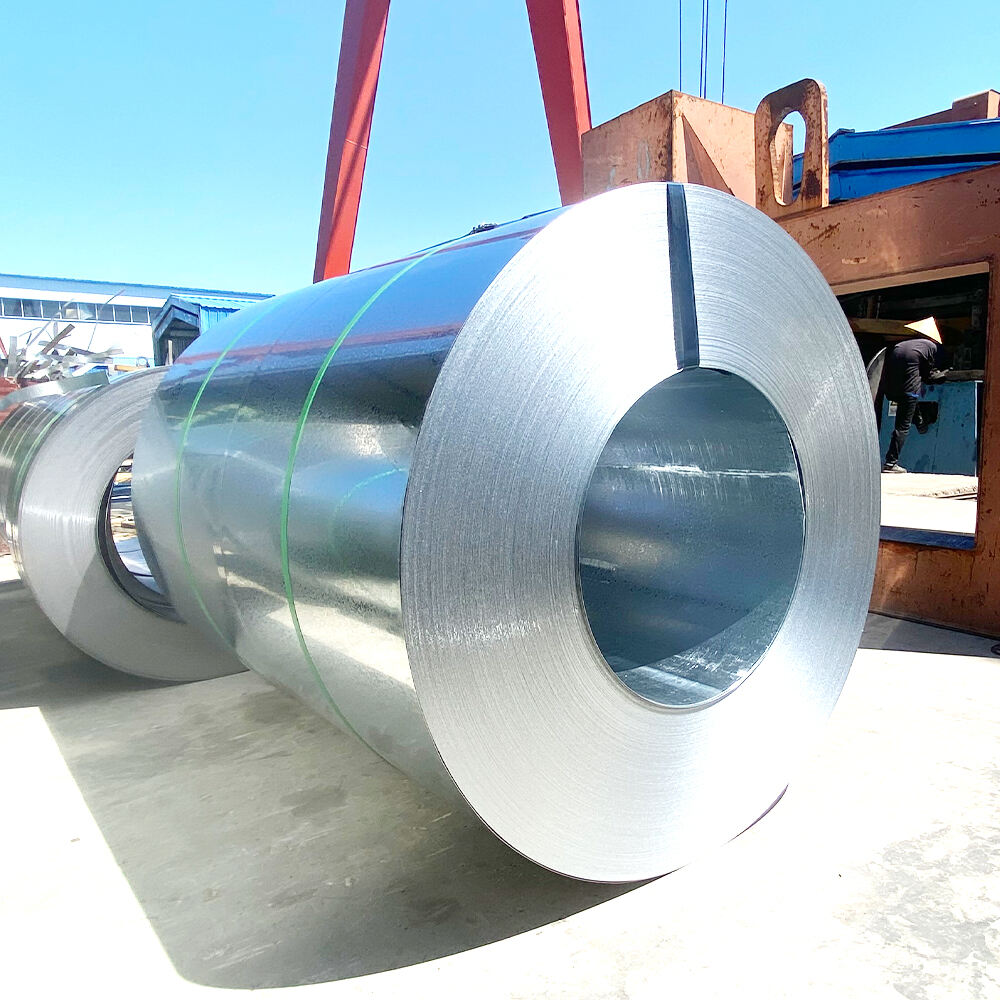

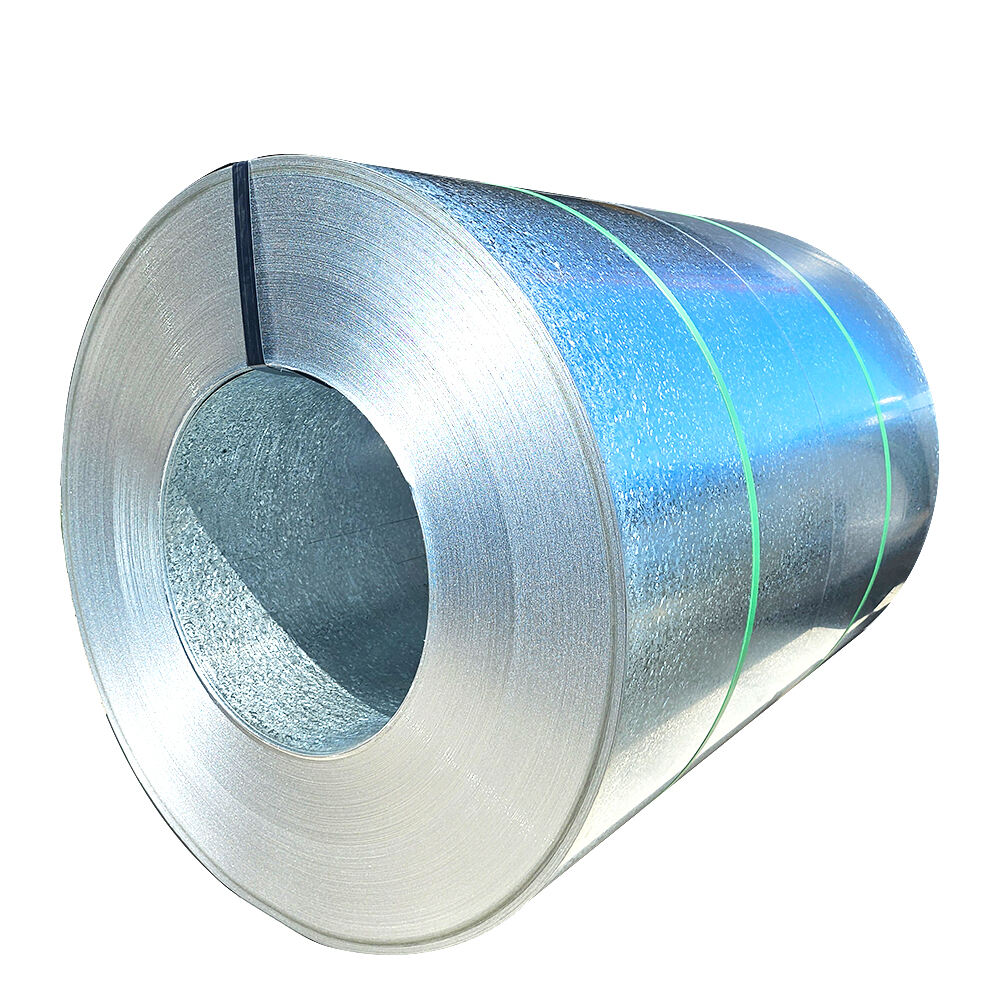

спангл гальванизированная сталь

Стальной прокат с цинковым покрытием в виде кристаллического узора представляет собой сложное металлургическое достижение, сочетающее долговечность и эстетическую привлекательность. Эта специализированная сталь подвергается процессу горячего цинкования, при котором расплавленный цинк наносится на поверхность стали, создавая характерный кристаллический узор, называемый «спангли». Размер и внешний вид этих спанглей можно контролировать путем точного регулирования скорости охлаждения и химического состава. Получаемое покрытие обеспечивает исключительную устойчивость к коррозии, сохраняя при этом прочностные характеристики основного металла. В процессе производства сталь проходит через ванну с расплавленным цинком при температуре около 450 °C, что позволяет цинку образовать металлическую связь с стальной основой. В результате формируются несколько слоев цинково-железных сплавов, поверх которых находится внешний слой чистого цинка, образующего характерный узор спанглей. Толщина покрытия обычно составляет от 20 до 100 микрон в зависимости от предполагаемого применения. Этот универсальный материал широко используется в строительстве, автомобилестроении и промышленности, где важны как защитные свойства, так и визуальная привлекательность.