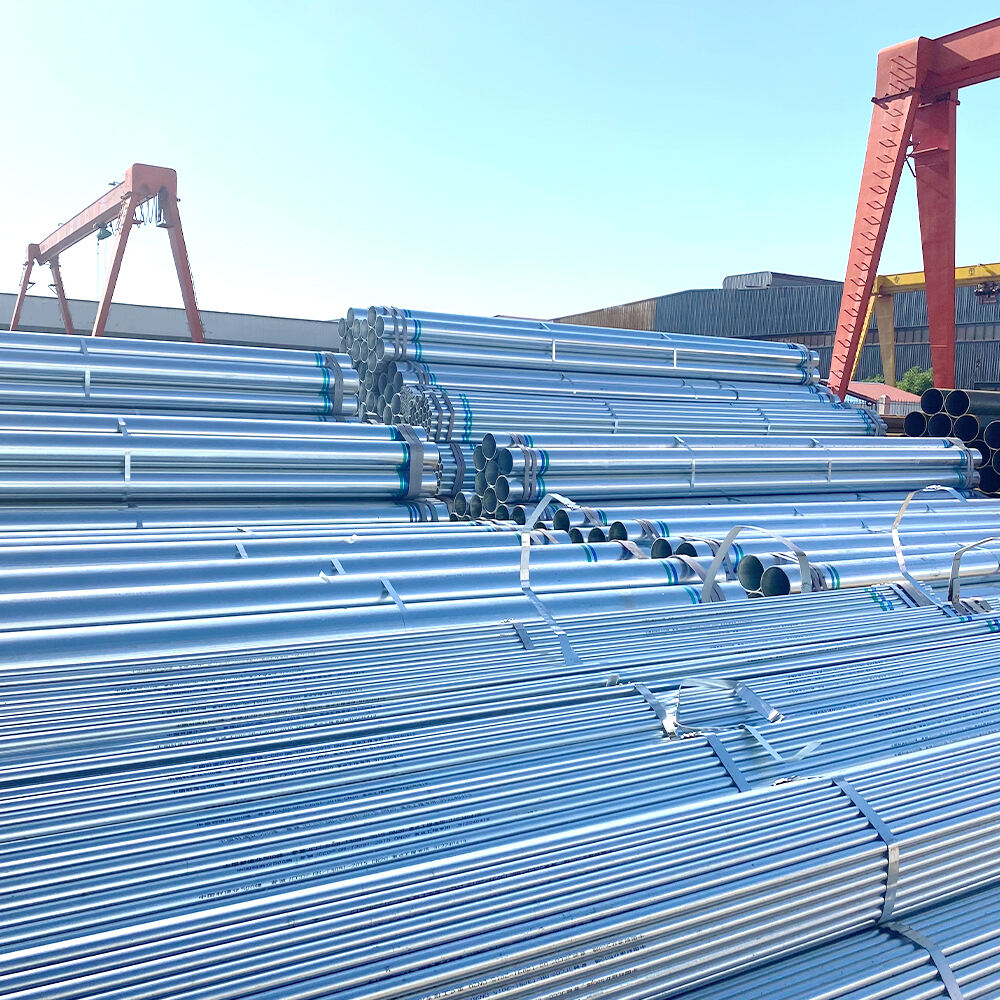

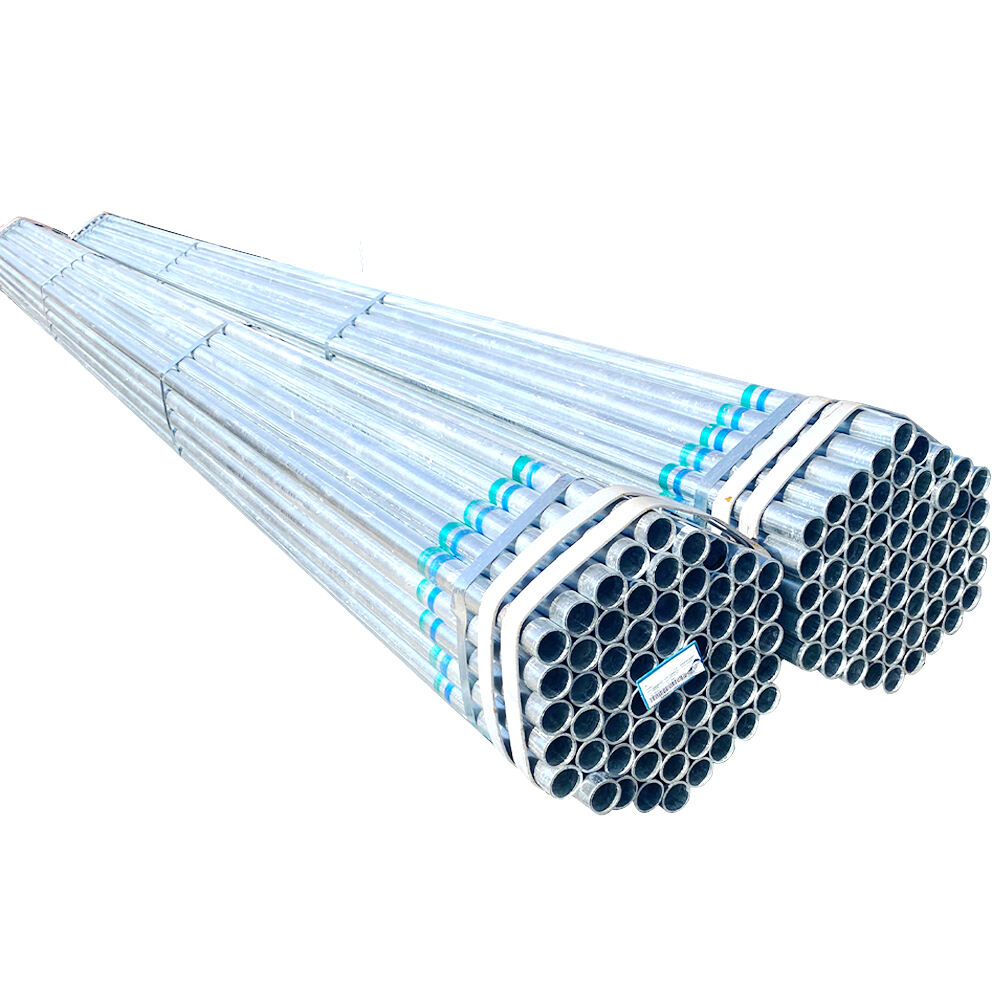

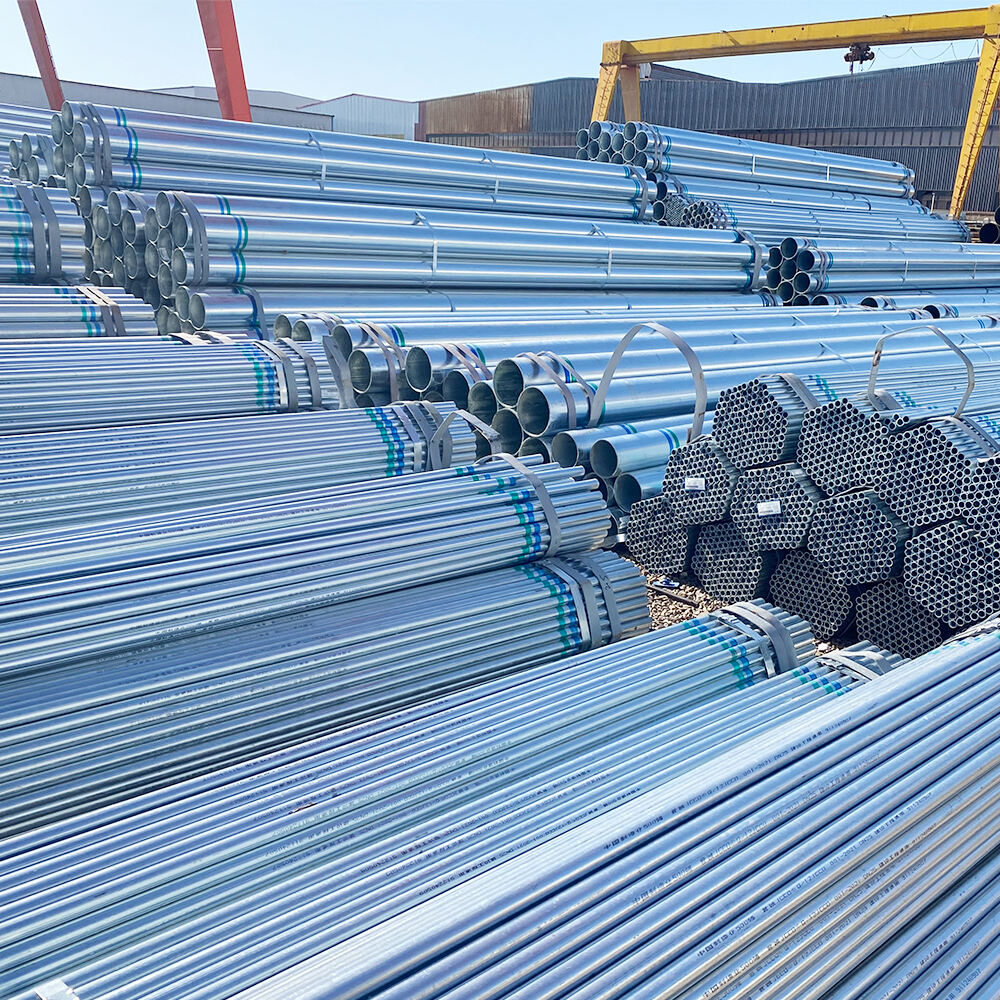

размеры оцинкованной стальной трубы

Размеры стальных оцинкованных труб представляют собой важный аспект современного строительства и промышленного применения, предлагая широкий диапазон размеров для удовлетворения разнообразных требований проектов. Эти трубы изготавливаются посредством специального процесса горячего цинкования, при котором стальные трубы покрываются защитным слоем цинка для повышения прочности и устойчивости к коррозии. Стандартные размеры обычно включают наружный диаметр, толщину стенки и длину, при этом распространенные диаметры варьируются от 1/2 дюйма до 8 дюймов. Толщина стенок варьируется в соответствии с номерами условных обозначений (schedule), чаще всего доступны варианты Schedule 40 и Schedule 80, обеспечивающие разные показатели давления и конструкционные характеристики. Процесс оцинковки добавляет примерно 0,05 мм до 0,1 мм толщины цинкового покрытия, что имеет решающее значение для долговечности. Эти размерные характеристики обеспечивают совместимость с типовыми фитингами и соединениями, сохраняя конструкционную целостность в различных областях применения — от систем водоснабжения до несущих конструкций.