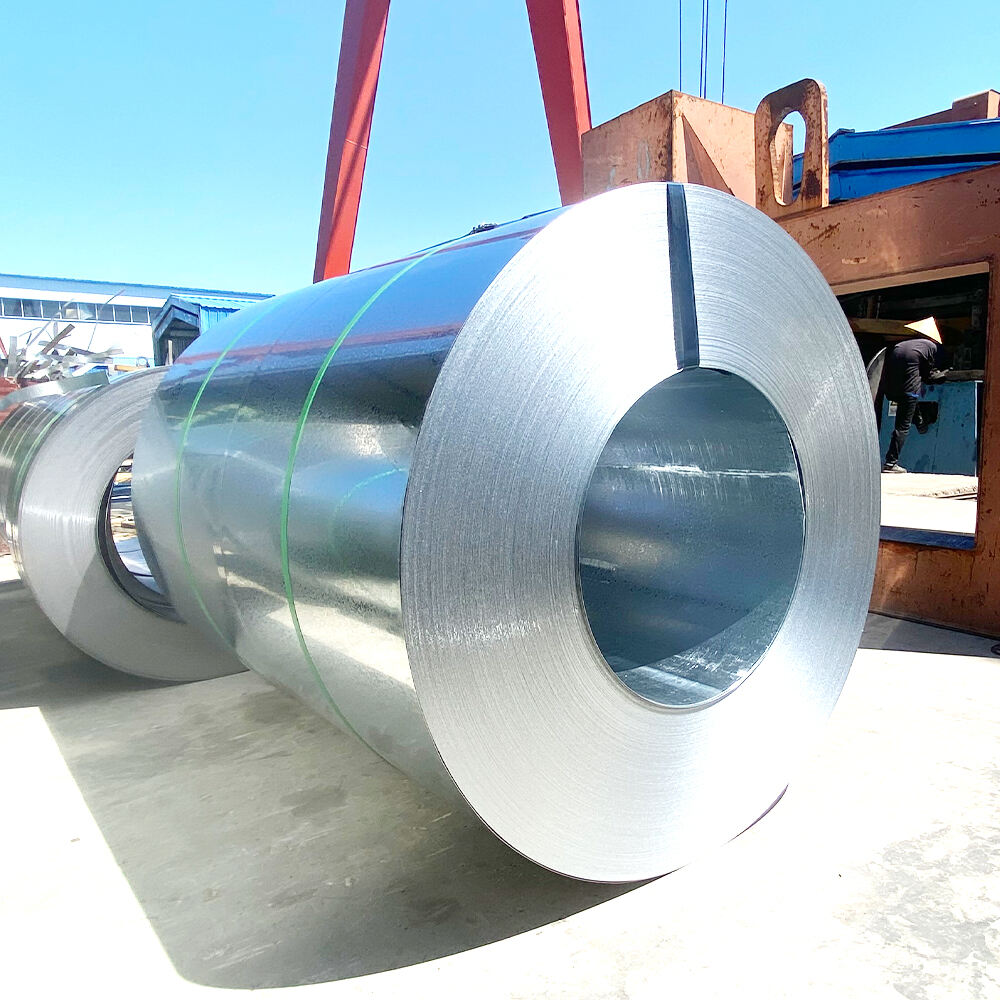

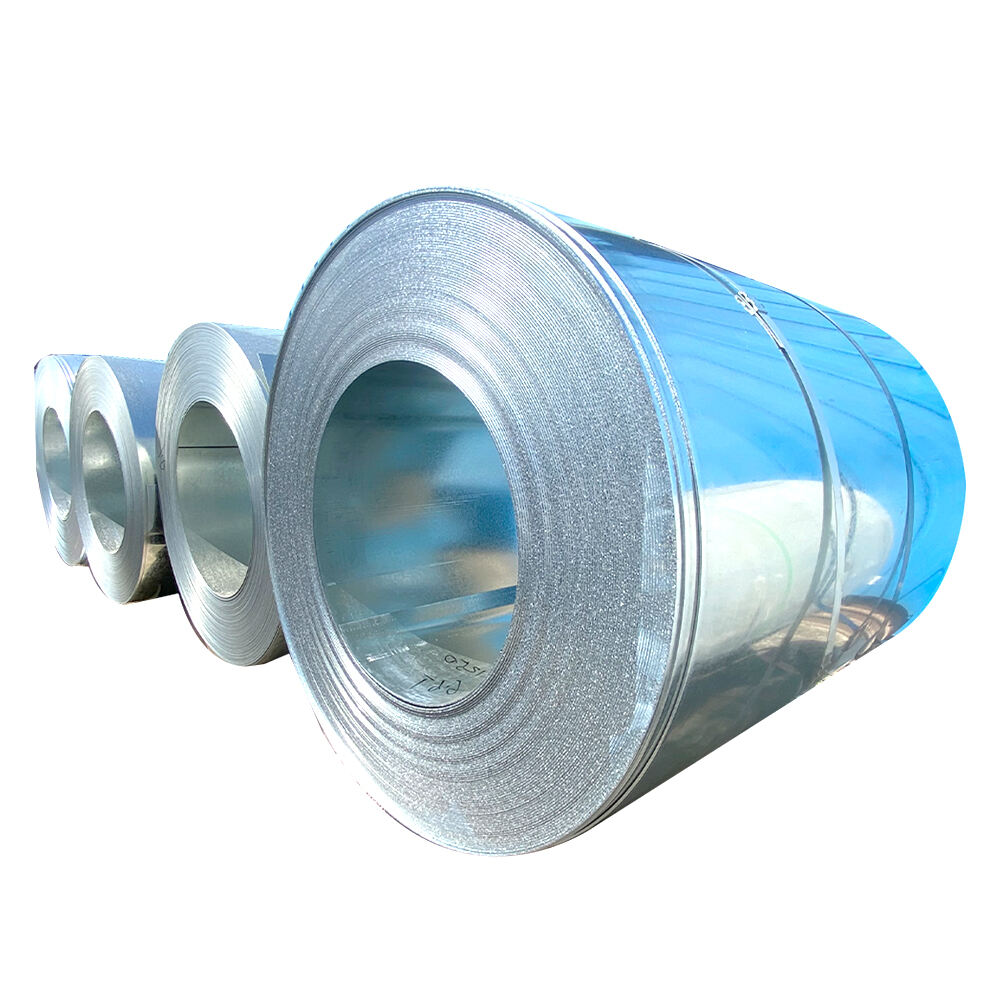

bobinas de chapa de metal galvanizado

As bobinas de chapas galvanizadas representam um componente essencial na construção e na fabricação modernas, oferecendo excepcional resistência à corrosão e durabilidade graças à sua superfície revestida de zinco. Essas bobinas são produzidas por meio de um processo sofisticado de galvanização a quente, no qual chapas de aço são imersas em zinco fundido a temperaturas próximas de 460°C. Esse tratamento cria uma camada protetora metalurgicamente ligada, que protege o metal de base contra fatores ambientais. O revestimento é composto por múltiplas camadas de ligas de zinco e ferro, culminando em uma camada externa de zinco puro que oferece proteção superior contra ferrugem e oxidação. Essas bobinas estão disponíveis em várias espessuras e larguras, tornando-as versáteis para diversas aplicações. Suas aplicações principais abrangem a construção civil, a fabricação automotiva, sistemas de climatização (HVAC) e equipamentos agrícolas. O revestimento de zinco não protege apenas o substrato de aço, mas também possui propriedades autorreparadoras, nas quais arranhões menores são protegidos pelo revestimento de zinco circundante por meio da ação galvânica. As bobinas modernas de chapas galvanizadas também possuem tratamentos superficiais aprimorados que melhoram a aderência de tintas e as características de resistência ao tempo, tornando-as ideais para aplicações internas e externas.