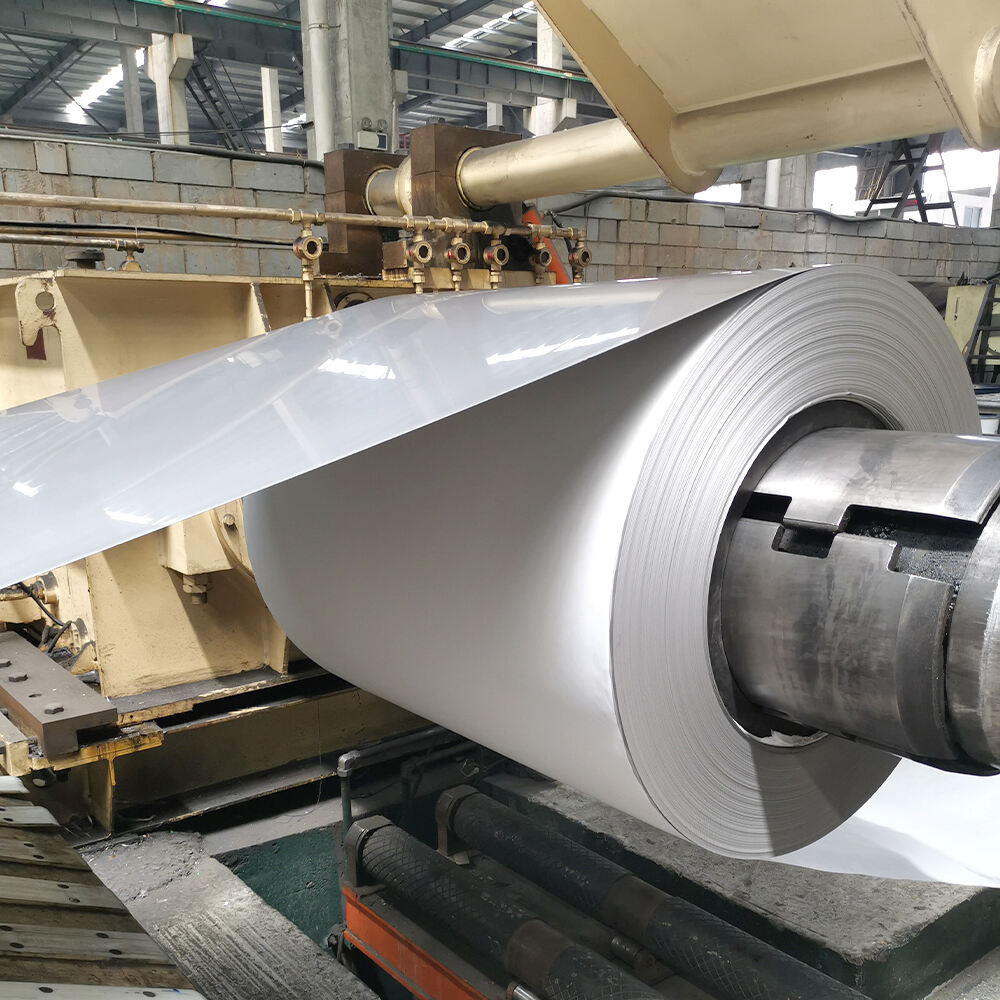

kepingan keluli tahan karat yang digulung sejuk

Gelung keluli tahan karat berguling sejuk mewakili produk logam gred premium yang dikeluarkan melalui proses berguling sejuk yang canggih, di mana keluli tahan karat diproses pada suhu bilik untuk mencapai kemasan permukaan yang unggul dan ketepatan dimensi yang tinggi. Teknik pengeluaran yang canggih ini menghasilkan gelung dengan kecembungan yang luar biasa, toleransi ketebalan yang terkawal, dan sifat mekanikal yang menonjol. Proses ini melibatkan pengurangan ketebalan keluli berguling panas dengan memampatkan dan memerahnya di antara penggelek tanpa sebarang pemanasan luaran. Hasilnya adalah produk yang menunjukkan kekuatan yang lebih tinggi, kehalusan permukaan yang lebih baik, dan kebolehbentukan yang lebih unggul berbanding rakan sejawatnya yang berguling panas. Gelung ini mempunyai rintangan korosi yang sangat baik, ketahanan yang luar biasa, dan kebolehgunaan yang pelbagai di pelbagai industri. Ia terutamanya dihargai dalam aplikasi yang memerlukan daya tarikan estetik, spesifikasi yang tepat, dan prestasi yang boleh dipercayai dalam keadaan yang mencabar. Ciri-ciri semula jadi bahan ini menjadikannya pilihan ideal untuk kedua-dua aplikasi hiasan dan fungsian, dari elemen seni bina sehingga ke komponen peralatan industri. Kekonsistenan dari segi kualiti dan ketepatan dimensi memastikan prestasi yang optimum dalam proses pengeluaran seterusnya, menjadikannya pilihan utama bagi industri yang memerlukan bahan berketepatan tinggi.