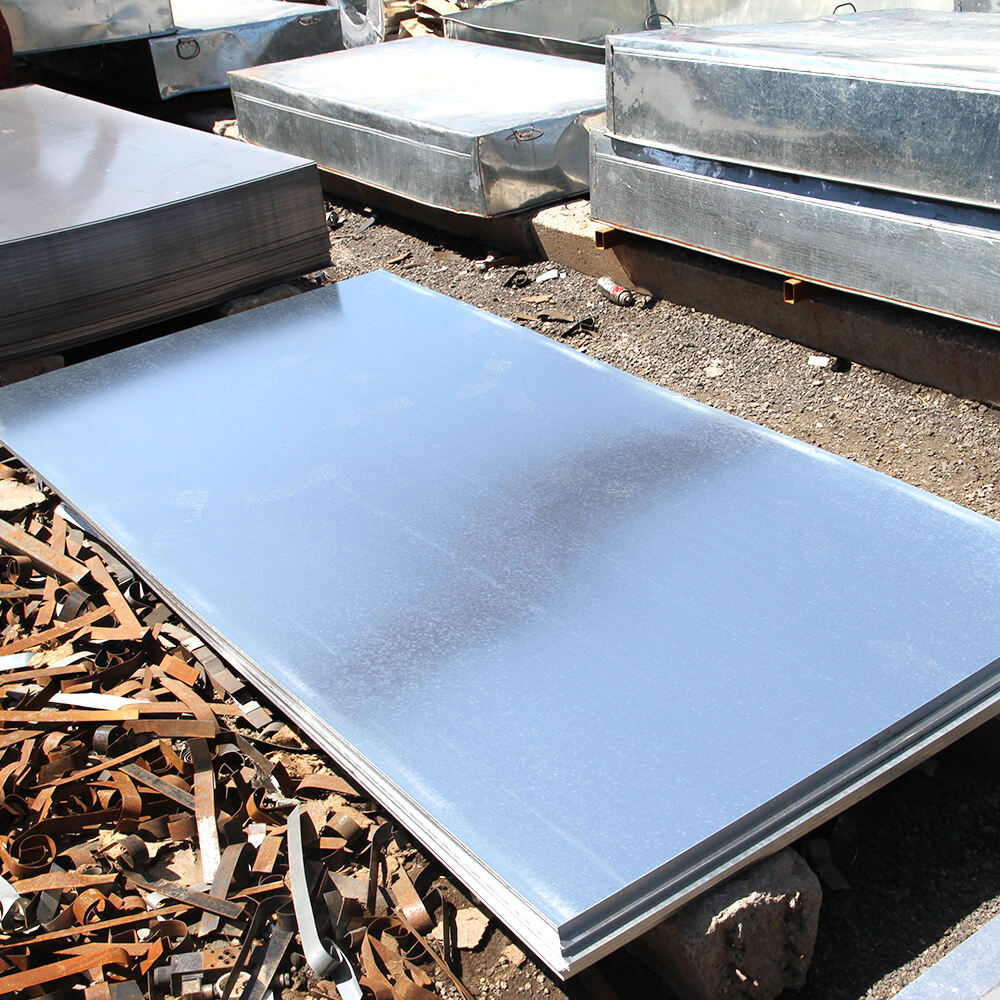

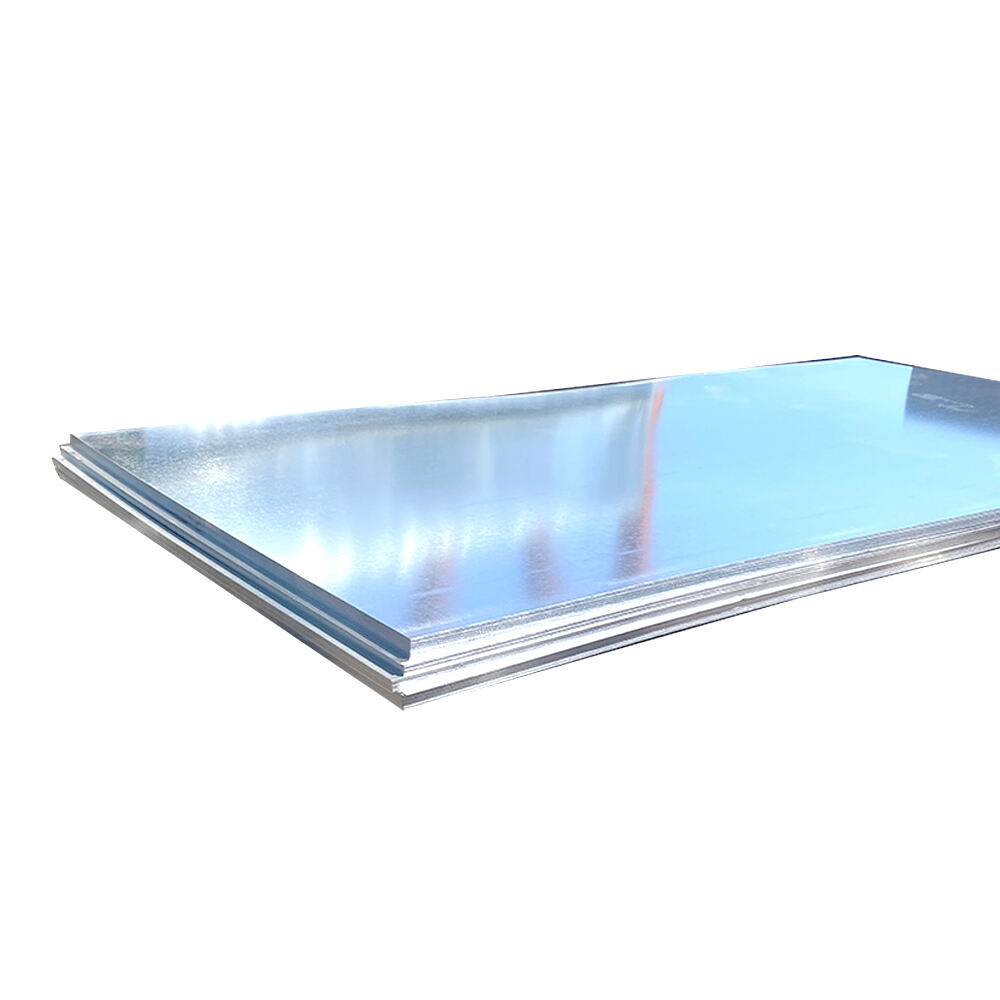

lembar logam baja galvanis

Lembaran baja galvanis merupakan puncak pencapaian dalam rekayasa metalurgi modern, menggabungkan daya tahan dengan fungsionalitas yang serbaguna. Material inovatif ini terdiri dari lapisan dasar baja yang melalui proses galvanisasi secara hot-dip khusus, di mana permukaannya dilapisi lapisan pelindung seng. Produk yang dihasilkan menawarkan ketahanan korosi yang luar biasa sambil mempertahankan integritas struktural baja. Proses galvanisasi menciptakan ikatan metalurgi antara lapisan seng dengan substrat baja, membentuk beberapa lapisan antarlogam yang memberikan perlindungan unggul terhadap faktor lingkungan. Lembaran ini diproduksi dalam berbagai ketebalan dan dimensi, memenuhi berbagai kebutuhan aplikasi industri dan komersial. Lapisan seng tidak hanya berfungsi sebagai lapisan korban yang melindungi baja di bawahnya dari oksidasi, tetapi juga menciptakan mekanisme self-healing, di mana goresan atau kerusakan kecil akan terlindungi oleh seng di sekitarnya. Material luar biasa ini digunakan secara luas dalam konstruksi, manufaktur otomotif, peralatan pertanian, serta pengembangan infrastruktur, menawarkan solusi ekonomis untuk proyek yang membutuhkan kekuatan dan ketahanan lama.