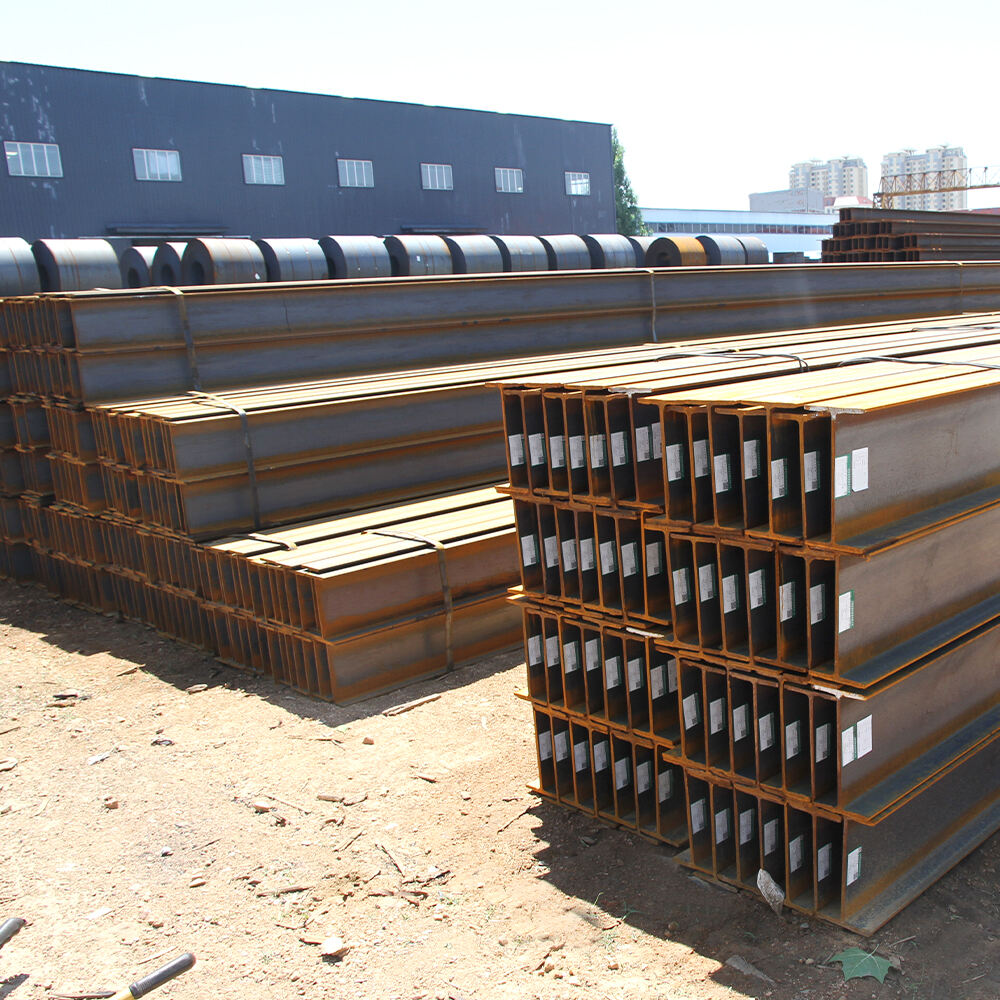

estaca de acero en hoja

Los tablestacas de acero son elementos estructurales versátiles ampliamente utilizados en proyectos de ingeniería civil y construcción. Estas secciones de acero con sistema de engranaje forman muros continuos que cumplen múltiples funciones en aplicaciones temporales y permanentes. El diseño presenta una serie de paneles interconectados que crean barreras estancas, haciéndolos ideales para estructuras en el agua, soporte de excavaciones y sistemas de protección contra inundaciones. Fabricados con acero de alta calidad, estos pilotes pasan por procesos rigurosos de control de calidad para garantizar durabilidad e integridad estructural. Su perfil característico en forma de Z o U permite una instalación eficiente y una resistencia máxima minimizando el uso de material. Las tablestacas de acero pueden ser hincadas en diversas condiciones del suelo, incluyendo arcilla, arena y suelos mixtos, utilizando equipos convencionales de hinca. Su naturaleza modular permite una instalación rápida, así como la posibilidad de extracción y reutilización en aplicaciones temporales. La resistencia a la corrosión puede mejorarse mediante recubrimientos o tratamientos protectores, prolongando su vida útil en ambientes agresivos. Las tablestacas de acero modernas incorporan principios avanzados de ingeniería para optimizar su desempeño en muros de contención, ataguías y estructuras marinas. Desempeñan un papel fundamental en el desarrollo de infraestructura, ofreciendo soluciones confiables tanto para desafíos constructivos sobre el nivel del suelo como bajo tierra.