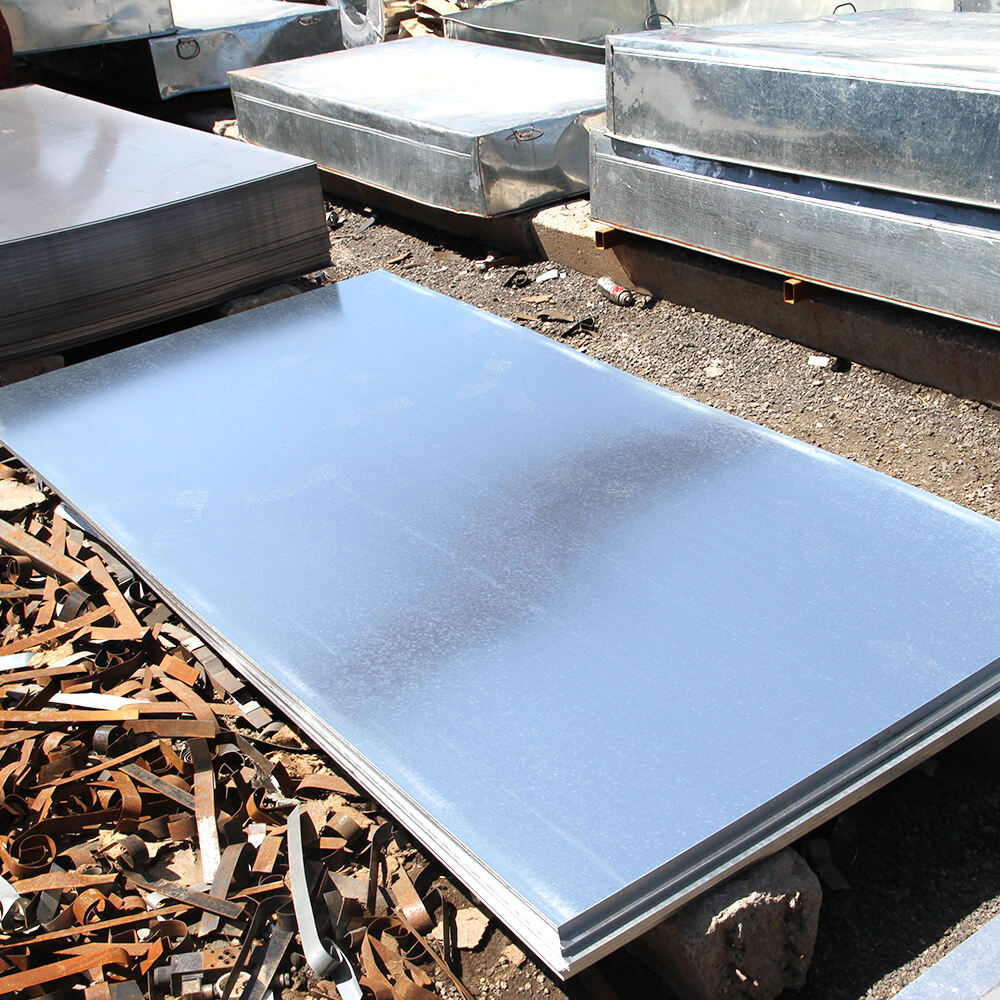

de acero blando laminado en caliente

La bobina de acero suave laminada en caliente representa un producto fundamental en la industria de fabricación de acero, caracterizada por sus propiedades versátiles y su proceso de producción económicamente eficiente. Este material pasa por un proceso de fabricación en el cual el acero se calienta por encima de su temperatura de recristalización y se procesa a través de una serie de rodillos para alcanzar el espesor y la forma deseados. La bobina resultante exhibe una excelente conformabilidad, soldabilidad y propiedades mecánicas que la hacen adecuada para numerosas aplicaciones industriales. El proceso de laminación en caliente mejora la resistencia del acero manteniendo su ductilidad, creando un producto que equilibra durabilidad con trabajabilidad. Estas bobinas generalmente contienen un contenido de carbono que varía entre 0,15 % y 0,30 %, proporcionando una combinación óptima de resistencia y maleabilidad. El acabado superficial de las bobinas laminadas en caliente presenta una escama de laminación distintiva, que puede ser beneficiosa en ciertas aplicaciones, mientras es fácilmente eliminable cuando se requiere. La precisión dimensional y la consistencia logradas mediante procesos modernos de laminación en caliente garantizan un desempeño confiable en diversas operaciones de fabricación, desde construcción hasta componentes automotrices.