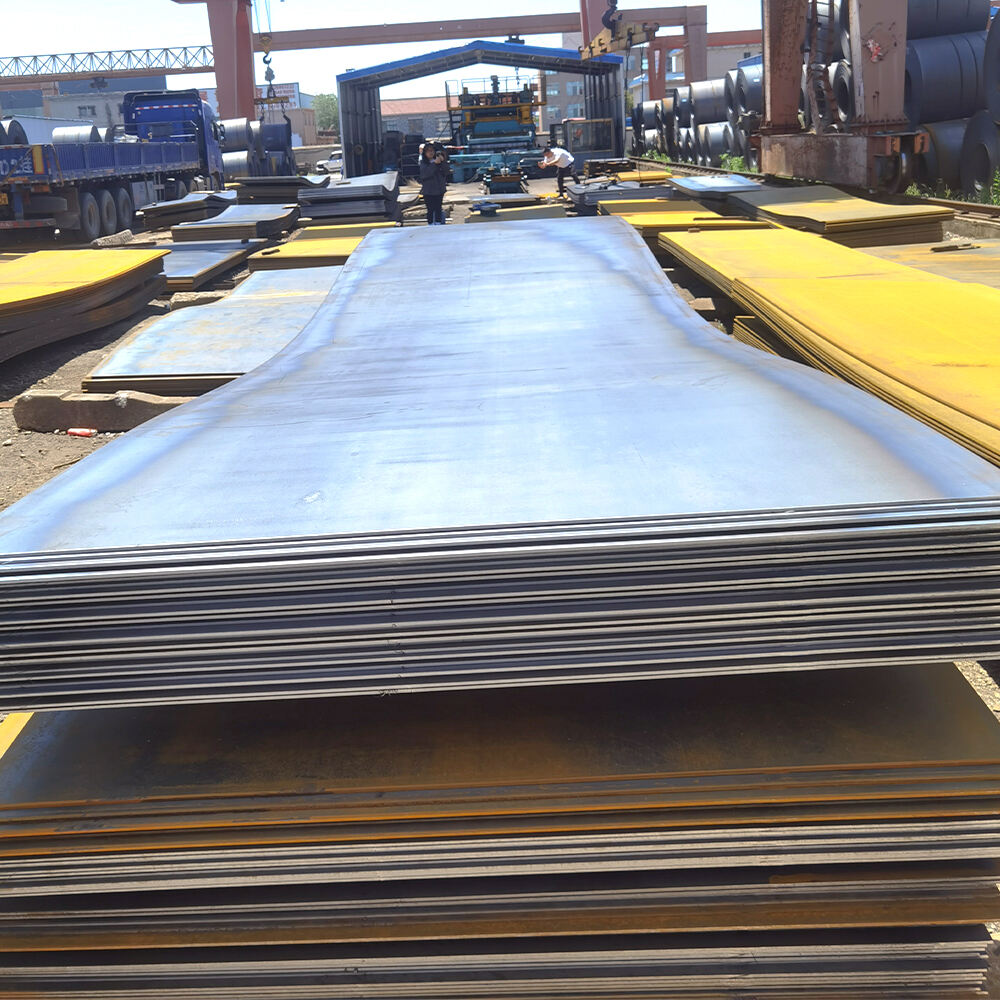

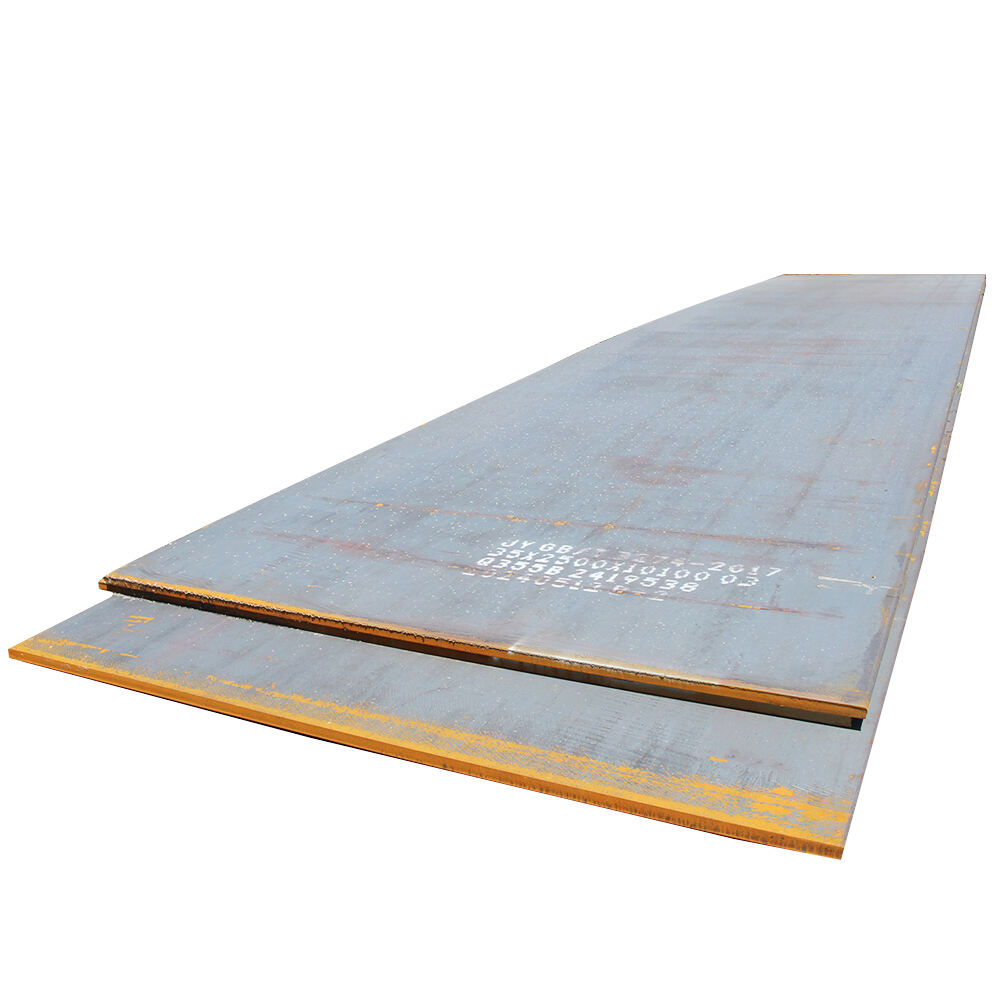

hoja de acero al carbono

La chapa de acero al carbono representa un material fundamental en la fabricación y construcción modernas, combinando resistencia, versatilidad y coste efectivo. Este material elaborado consiste en hierro aleado con carbono, conteniendo típicamente entre 0.05% y 2.1% de contenido de carbono, lo cual influye significativamente en sus propiedades mecánicas. El proceso de fabricación implica un control cuidadoso de la temperatura y técnicas de laminación para producir chapas de diversos espesores, que van desde calibres ultrafinos hasta configuraciones de placas gruesas. Estas chapas presentan una relación resistencia-peso excepcional y se pueden fabricar fácilmente mediante operaciones de corte, doblado, soldadura y conformado. Las características inherentes del material lo hacen ideal para aplicaciones estructurales, componentes automotrices, equipos industriales y elementos arquitectónicos. La chapa de acero al carbono también demuestra una durabilidad notable bajo diversas condiciones ambientales, aunque un tratamiento superficial adecuado es esencial para lograr una resistencia óptima a la corrosión. La uniformidad y consistencia del material en su producción garantizan un desempeño confiable en diferentes aplicaciones, mientras que su maleabilidad permite operaciones complejas de conformado sin comprometer la integridad estructural. Las técnicas modernas de fabricación han mejorado el control de calidad del material, resultando en chapas con tolerancias precisas y acabados superficiales superiores.