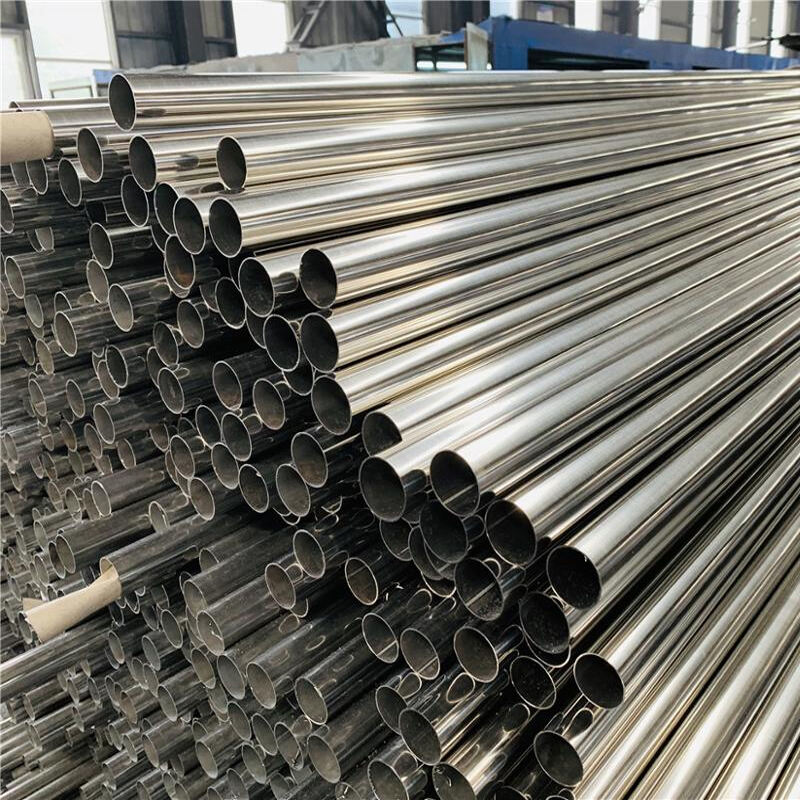

rohr aus rostfreiem Stahl

Rohre aus rostfreiem Stahl ohne Naht stellen ein entscheidendes Element in modernen Industrieanwendungen dar. Sie werden mithilfe eines fortschrittlichen Verfahrens hergestellt, das eine gleichmäßige Festigkeit und Integrität über die gesamte Struktur gewährleistet. Diese spezielle Rohrleitung wird ohne geschweißte Nähte produziert, wodurch eine durchgängige, homogene Struktur entsteht, die Zuverlässigkeit und Leistung maximiert. Der Herstellungsprozess umfasst Warm-Extrusion oder Durchsetzverfahren, gefolgt von präzisem Kaltziehen oder Kaltwalzen, um die gewünschten Abmessungen und Spezifikationen zu erreichen. Diese Rohre werden aus hochwertigen Legierungen rostfreier Stähle gefertigt und bieten eine außergewöhnliche Beständigkeit gegen Korrosion sowie Druck- und Temperaturschwankungen. Die nahtlose Konstruktion beseitigt potenzielle Schwachstellen, wie sie bei geschweißten Verbindungen üblich sind, wodurch diese Rohre ideal für Anwendungen sind, bei denen unter anspruchsvollen Bedingungen kontinuierliche Leistung erforderlich ist. Ihre Vielseitigkeit erstreckt sich über verschiedene Branchen, darunter chemische Industrie, Öl- und Gasförderung, Kernenergieerzeugung und pharmazeutische Produktion. Die hervorragenden mechanischen Eigenschaften dieser Rohre, einschließlich überlegener Zugfestigkeit und Duktilität, garantieren langfristige Zuverlässigkeit und reduzierte Wartungskosten. Zudem sorgt ihre glatte Innenfläche für optimale Strömungseigenschaften und minimiert das Risiko von Ablagerungen oder Kontamination.