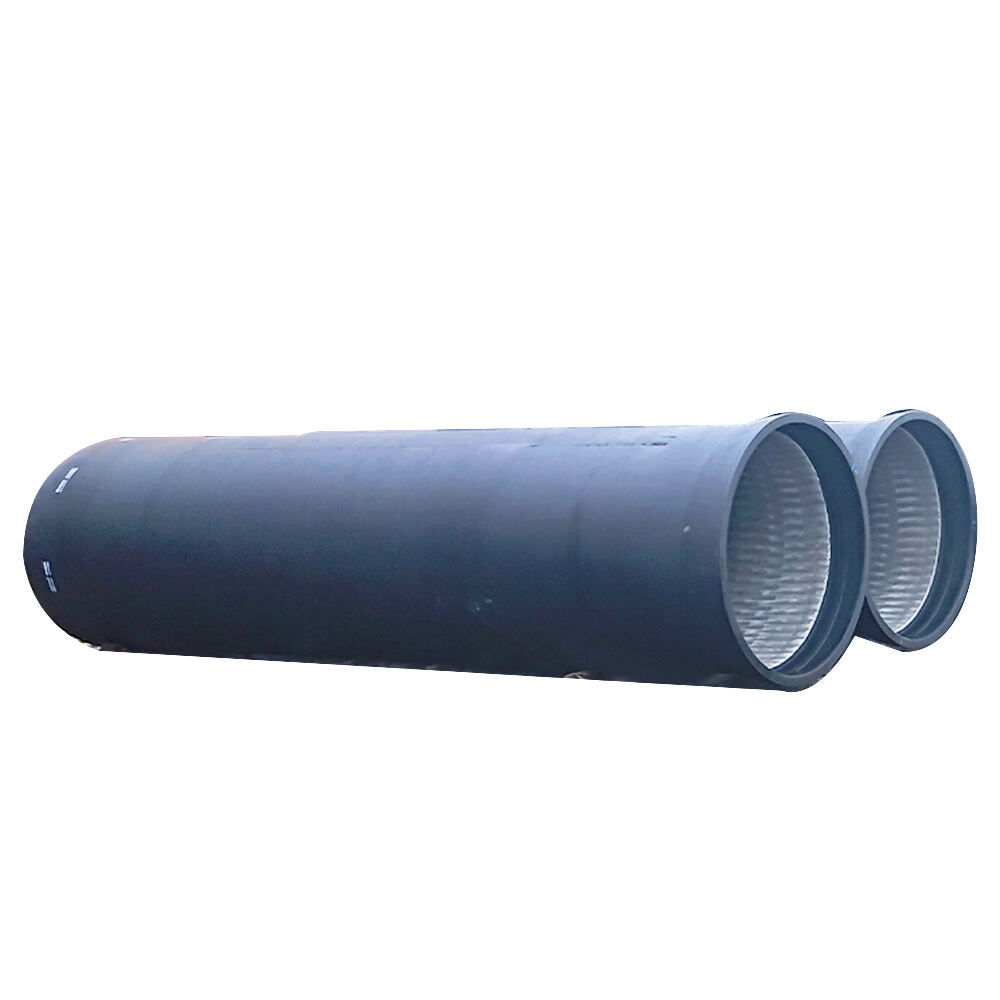

ডাকটাইল আয়রন পাইপওয়ার্ক

নমনীয় লোহার পাইপওয়ার্ক জল ও নিকাশী অবকাঠামোর ক্ষেত্রে বিপ্লবী অগ্রগতি উপস্থাপন করে, যা উচ্চতর যান্ত্রিক বৈশিষ্ট্যগুলির সাথে স্থায়িত্বকে একত্রিত করে। এই আধুনিক পাইপিং সমাধানটি একটি উদ্ভাবনী ধাতুবিদ্যা পদ্ধতির মাধ্যমে তৈরি করা হয় যা গলিত লোহার মধ্যে ম্যাগনেসিয়াম যোগ করে, যার ফলে একটি উপাদান যা অসাধারণ শক্তি এবং নমনীয়তা প্রদর্শন করে। নমনীয় লোহার গ্রাফাইট ফ্লেকসের পরিবর্তে গোলাকার নোডুল গঠন করে, একটি কাঠামো তৈরি করে যা ফাটল প্রতিরোধী এবং চরম চাপের অবস্থার প্রতিরোধ করে। এই পাইপগুলি 350 থেকে 400 PSI পর্যন্ত চাপ পরিচালনা করতে ডিজাইন করা হয়েছে, যা তাদের জল বিতরণ এবং বর্জ্য ব্যবস্থাপনা উভয় সিস্টেমের জন্য আদর্শ করে তোলে। এই উপাদানটির অন্তর্নিহিত ক্ষয় প্রতিরোধ ক্ষমতা সুরক্ষা লেপ এবং আস্তরণের মাধ্যমে উন্নত করা হয়, যা প্রায়শই 100 বছরেরও বেশি সময় ধরে পরিষেবা জীবন নিশ্চিত করে। নমনীয় লোহার পাইপগুলি 3 থেকে 64 ইঞ্চি ব্যাসার্ধে পাওয়া যায়, বিভিন্ন প্রবাহের প্রয়োজনীয়তা এবং ইনস্টলেশন দৃশ্যকল্পের জন্য। তাদের বহুমুখিতা উভয় ভূগর্ভস্থ এবং কবর অ্যাপ্লিকেশন জন্য অনুমতি দেয়, যখন তাদের দৃঢ় প্রকৃতি তাদের মাটি আন্দোলন বা ভূমিকম্পের কার্যকলাপের প্রবণতা এলাকায় বিশেষভাবে উপযুক্ত করে তোলে। সিস্টেমের যৌথ নকশাগুলিতে ধাক্কা, যান্ত্রিক এবং সংযত বিকল্পগুলি অন্তর্ভুক্ত রয়েছে, ইনস্টলেশন এবং রক্ষণাবেক্ষণ পদ্ধতিতে নমনীয়তা সরবরাহ করে।