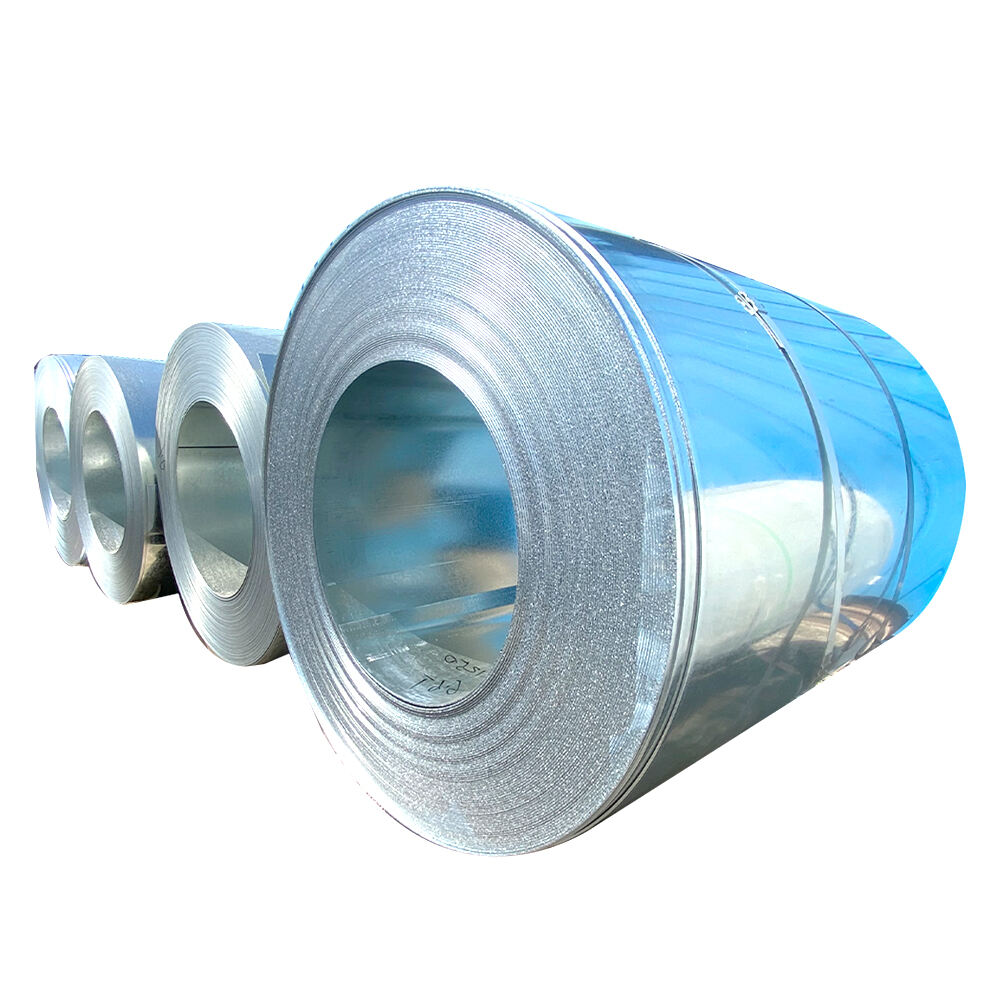

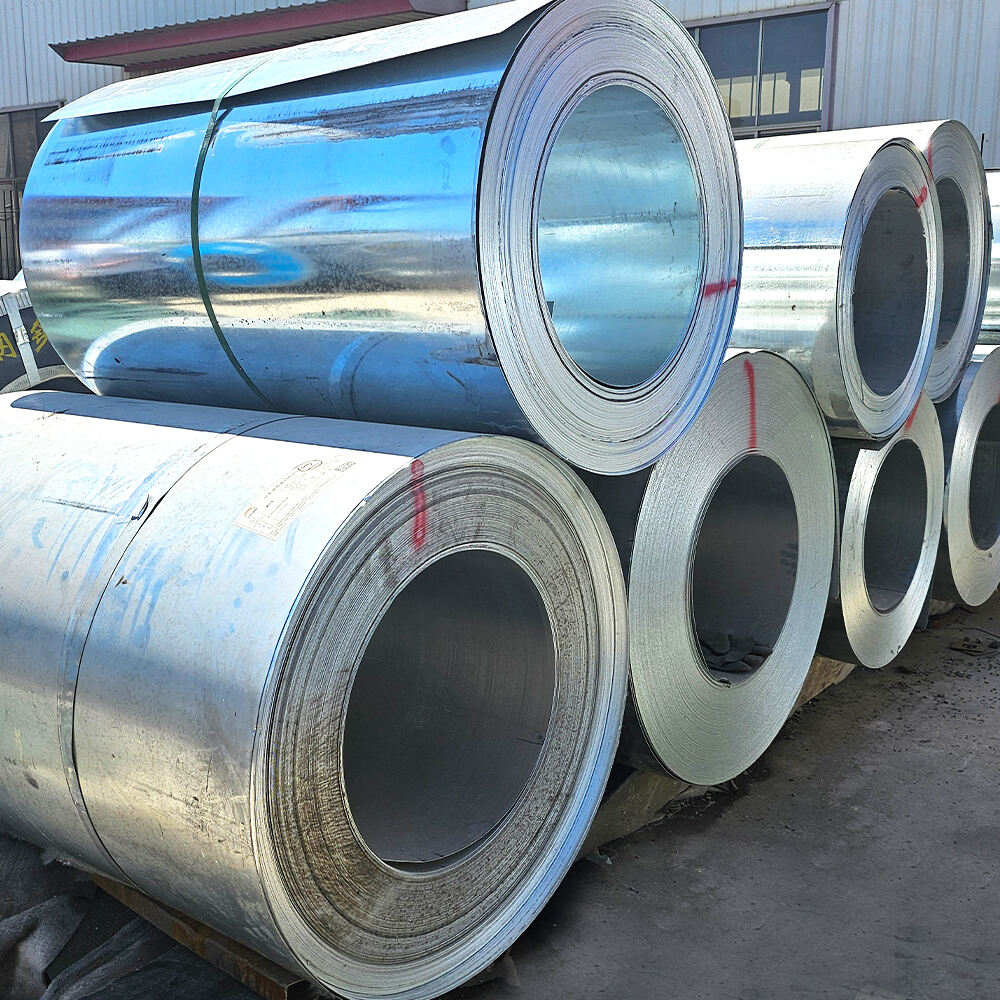

hot dipped galvanized steel coils

Hot dipped galvanized steel coils represent a premium steel product manufactured through an advanced metallurgical process where steel strips are immersed in molten zinc. This coating process creates a metallurgically bonded zinc layer that provides superior corrosion resistance and extended service life. The process involves cleaning the steel surface, followed by immersion in a bath of molten zinc at approximately 860°F (460°C). During this process, the zinc reacts with the steel surface to form several zinc-iron alloy layers, culminating in a pure zinc outer layer. The resulting coating offers a distinctive spangle pattern and a robust protective barrier against environmental factors. These coils find extensive applications across various industries, including construction, automotive manufacturing, and infrastructure development. The coating thickness can be precisely controlled to meet specific industry standards and customer requirements, typically ranging from G30 to G235. The versatility of hot dipped galvanized steel coils makes them ideal for both indoor and outdoor applications, particularly in environments where corrosion resistance is crucial. The product's durability, combined with its cost-effectiveness and minimal maintenance requirements, has established it as a cornerstone material in modern industrial applications.