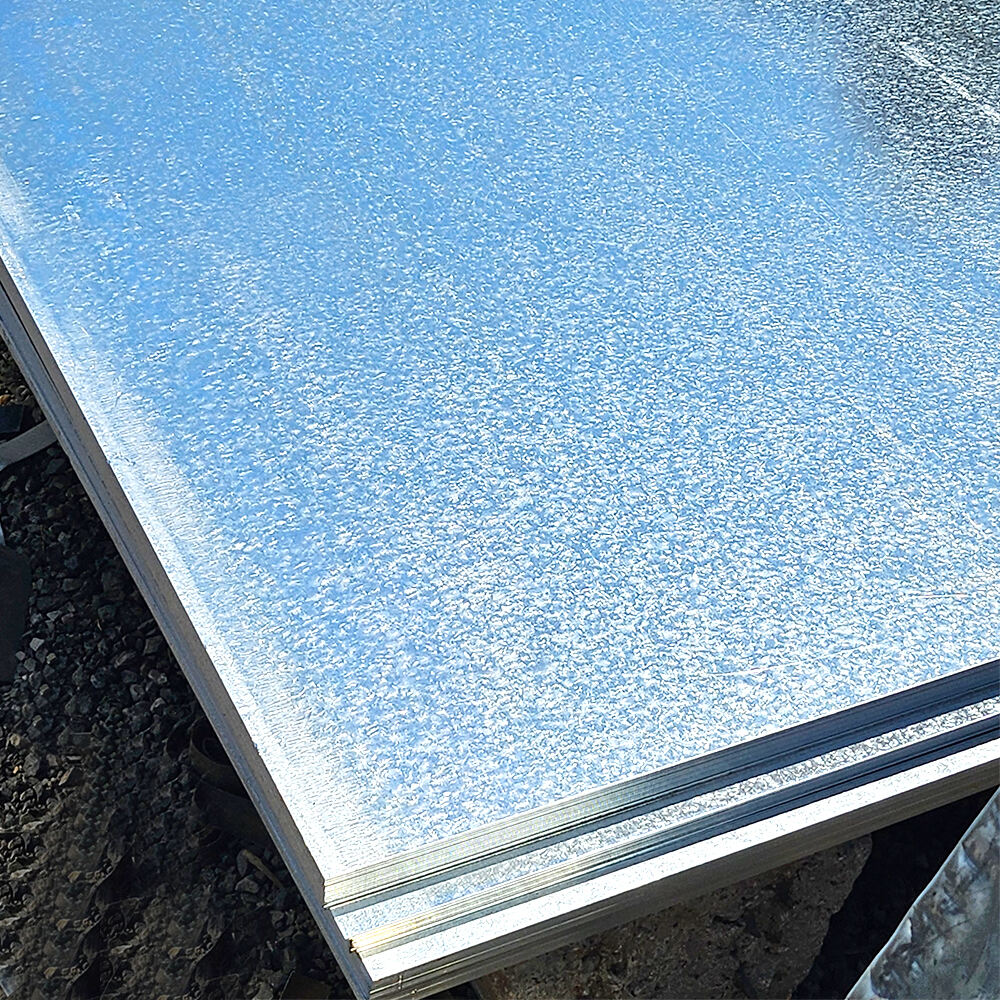

galvanized steel sheet

Galvanized steel sheet represents a crucial advancement in metal protection technology, combining durability with versatile application potential. This innovative material consists of a steel base coated with a protective layer of zinc through a specialized hot dip galvanization process. The zinc coating creates a robust barrier against corrosion, effectively shielding the underlying steel from environmental factors that could cause deterioration. The galvanization process involves immersing the steel sheet in molten zinc at temperatures around 860°F (460°C), during which a metallurgical bond forms between the zinc and steel, creating multiple layers of zinc-iron alloys. This results in a material that offers superior resistance to rust and corrosion compared to uncoated steel. The galvanized coating also provides self healing properties, where any minor scratches or damages are protected by the surrounding zinc coating through sacrificial protection. These sheets find extensive applications across various industries, from construction and automotive to manufacturing and agricultural sectors. The material's strength, coupled with its protective qualities, makes it ideal for roofing, wall cladding, automotive parts, and various structural applications where exposure to harsh environmental conditions is a concern.