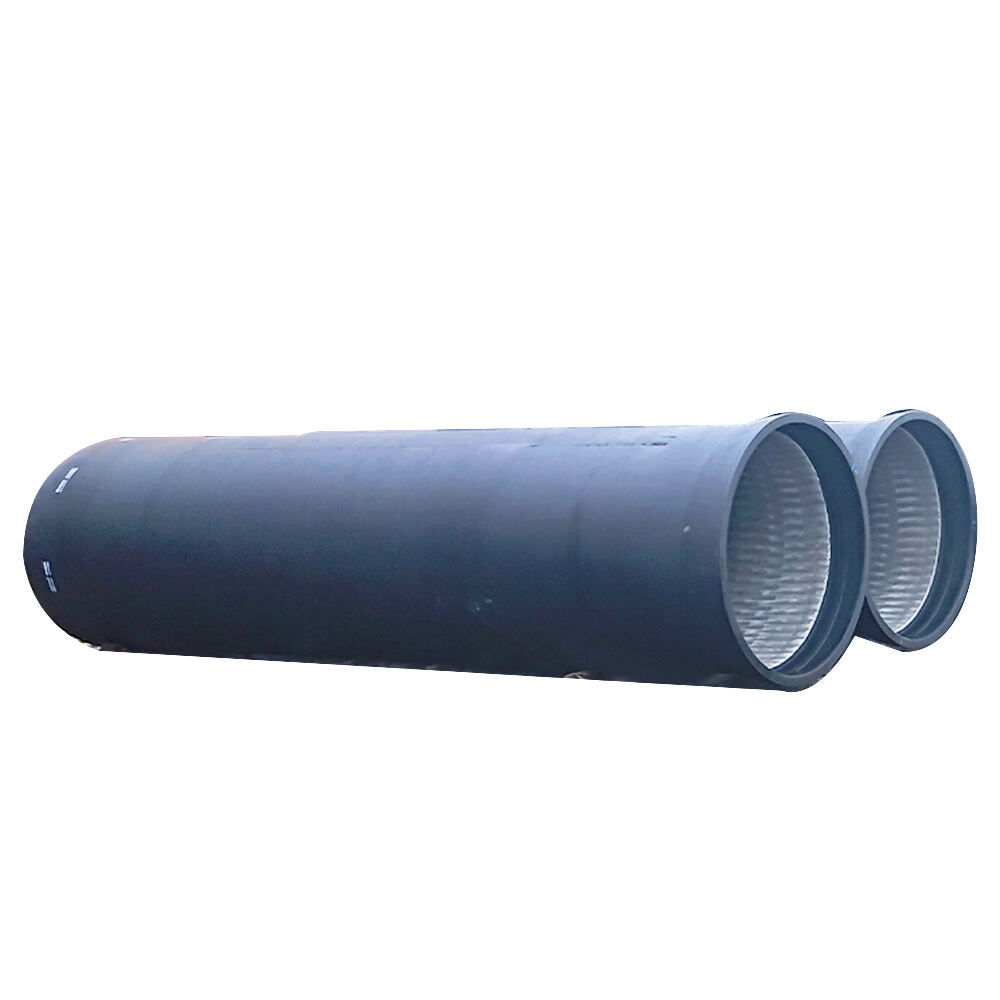

ductile iron pipe

Ductile iron pipe represents a revolutionary advancement in water and wastewater infrastructure, combining durability with superior performance characteristics. This innovative piping solution is manufactured through a sophisticated metallurgical process that introduces magnesium into molten iron, resulting in a material that exhibits remarkable strength and flexibility. The pipe's structure features graphite in spheroidal form, rather than the flake form found in traditional cast iron, which significantly enhances its mechanical properties. Ductile iron pipes are designed to withstand high pressure ratings, typically ranging from 350 to 400 psi, making them ideal for demanding applications. These pipes excel in both water distribution and sewage systems, offering a service life that can exceed 100 years when properly installed and maintained. The pipe's internal diameter remains consistent throughout its length, ensuring optimal flow efficiency and minimal pressure loss. Additionally, the material's inherent corrosion resistance is further enhanced by protective coatings and linings, such as cement mortar or polyethylene encasement, which provide comprehensive protection against aggressive soil conditions and internal erosion. Modern ductile iron pipes also incorporate advanced joint designs, including push-on and mechanical joints, that facilitate rapid installation while maintaining system integrity.