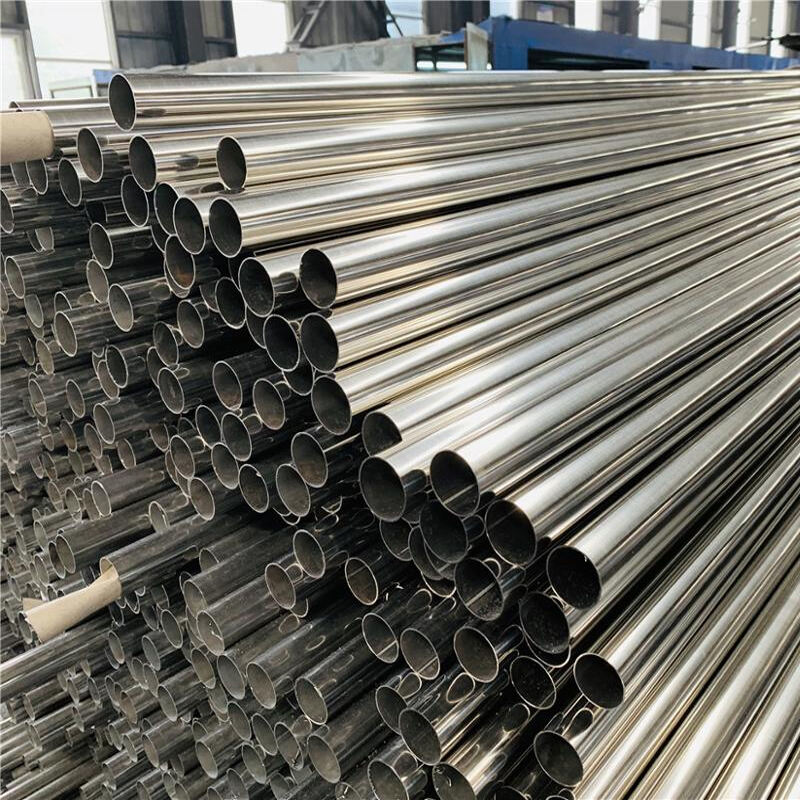

ከማይዝግ ብረት የተሸመነ ቱቦ

የስቴይንሌስ ብረት የተያያዥ ቱቦ በአሁኑ የኢንዱስትሪ መተግበሪያዎች ውስጥ አስፈላጊ አካል ነው፣ ይህም የተሻለ የመቆጣጠር እና የተሻለ ጥራት ለማረጋገጥ የተሻለ የመዋኛ ሂደት በመጠቀም ይዘጋጃል። ይህ ቱቦዎች በስቴይንሌስ ብረት ዓላቶች ሲሊንደር ቅርፅ ወደ መታጠፊያ እና በትክክለኛ የመዋኛ ቴክኒኮች በመገጣጠም የተገነቡ ናቸው። የማምረት ሂደቱ የመታወቂያ ጥራት ቁጥጥር እንዲኖርበት ያደርጋል፣ ይህም የአልትራሶኒክ ፈተና እና የሃይድሮስታቲክ ግፊት ፈተናን ያካትታል የመዋቅር ጠንካራነስ ለማረጋገጥ። ይህ ቱቦዎች በጣም የተሻለ የመበላሸት ችሎታ አላቸው፣ ይህም በከፍተኛ የክሮሚየም ቁጥር ምክንያት ነው፣ ይህም ለሙቀት፣ ኬሚካሎች እና ለተለያዩ የሙቀት መጠኖች ዝግጅት የተጠቃሚ ነው። ይህ ቱቦዎች በተለያዩ የሥራ ሁኔታዎች ውስጥ የመታጠፊያ እና የሥራ ችሎታ ይጠብቁታል፣ ከጣዕሚ ብርዝግ እስከ ከፍተኛ ሙቀት ድረስ። የመጠኖች ትክክለኛነት እና የውሂብ ጠርዞች የዚህ ቱቦዎችን ጥቅም ለትክክለኛ መስፈርቶች የሚያስፈልጉ መተግበሪያዎች ለመጠቀም በጣም ተስማሚ ያደርገዋል። የተለያዩ መተግበሪያዎች የኬሚካል ሂደቶችን፣ የምግብ እና የመጠጥ ምርትን፣ የፋርማሲውቲካል ማምረትን፣ የውሃ አሻሽሎ ሥርዓቶችን እና የመንደፍ ፕሮጀክቶችን ያካትታሉ። ይህ ቱቦዎች በተለያዩ ደረጃዎች፣ መጠኖች እና የቁርጠት ጥላማዎች ይገኛሉ ለተለያዩ ግፊት ደረጃዎች እና የአካባቢ መስፈርቶች ለማክበር። የእነሱ ተግባራዊነት ወደ ሁለቱም የኢንዱስትሪ ሂደቶች እና የንግድ ማሰራጫ የሚጠቀሙበት የተረጋጉ መተላለፊያዎች ለማቅረብ፣ ጋዝ እና ሉጥ ያለው ነው።