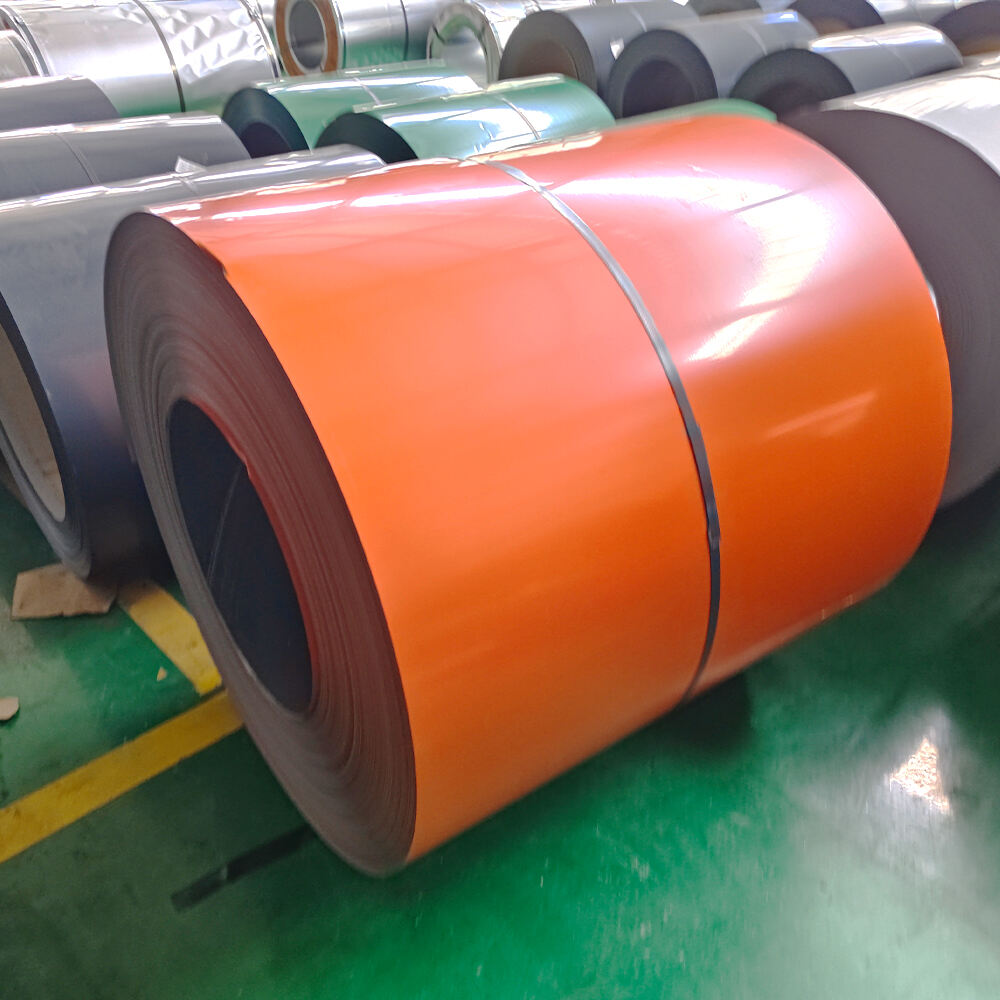

የፒፒጂ ኮይል

የ PPGI ጥቅል ወይም ቅድመ-ቀለም የተቀባ የብረት ጥቅል፣ ዘላቂነትን ከጌጣጌጥ ጋር የሚያጣምር የተራቀቀ የግንባታ ቁሳቁስ ነው። ይህ የተሠራ ምርት በሙቅ ሙቀት የተገመደ የብረት ንጣፍ ሲሆን ከዚያ በኋላ ልዩ ቅድመ-ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀ የብረት ንጣፍ በዝውውር ዚንክ መታጠቢያ ውስጥ በመጥለቅ የዚንክ ሽፋን ይቀበላል ፣ ይህም ከዝገት የሚከላከል መሰናክል ይፈጥራል። ከጊዜ በኋላ ቁሳቁሱ በጥንቃቄ ቁጥጥር የሚደረግበት ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም ቀለም የምርት ሂደቱ የወለል ንጣፍ፣ የቅድመ-ማጣሪያ ሽፋን፣ የጨርቃ ጨርቅ ሽፋን እና የተከታታይ የምርት ጥራት ለማረጋገጥ የጥራት ቁጥጥር እርምጃዎችን ያካትታል። የ PPGI ጥቅል በተለያዩ ኢንዱስትሪዎች ውስጥ በተለይም በግንባታ ውስጥ ለጣሪያ ፣ ለግድግዳ ሽፋን እና ለአርኪቴክቸር ፓነሎች ጥቅም ላይ የሚውሉ ሰፊ አተገባበርን ያገኛሉ ። የቁሳቁሱ ሁለገብነት በቤት ውስጥ መገልገያዎች፣ በኤች ቪ ኤሲ ስርዓቶች እና በአውቶሞቲቭ አካላት ምርት ላይ ጥቅም ላይ በሚውልበት ወደ ማምረቻ ዘርፎች ይስፋፋል። የተለመደው የምርት ሂደት አንድ ዓይነት የሽፋን ውፍረትና በደረጃዎች መካከል ያለው ተጣብቆ መቆየት እንዲኖር ያደርጋል፤ ይህም ምርቱ ለረጅም ጊዜ መልክና መዋቅራዊ ጥንካሬውን ጠብቆ እንዲቆይ ያደርጋል።