የብረት ኤች

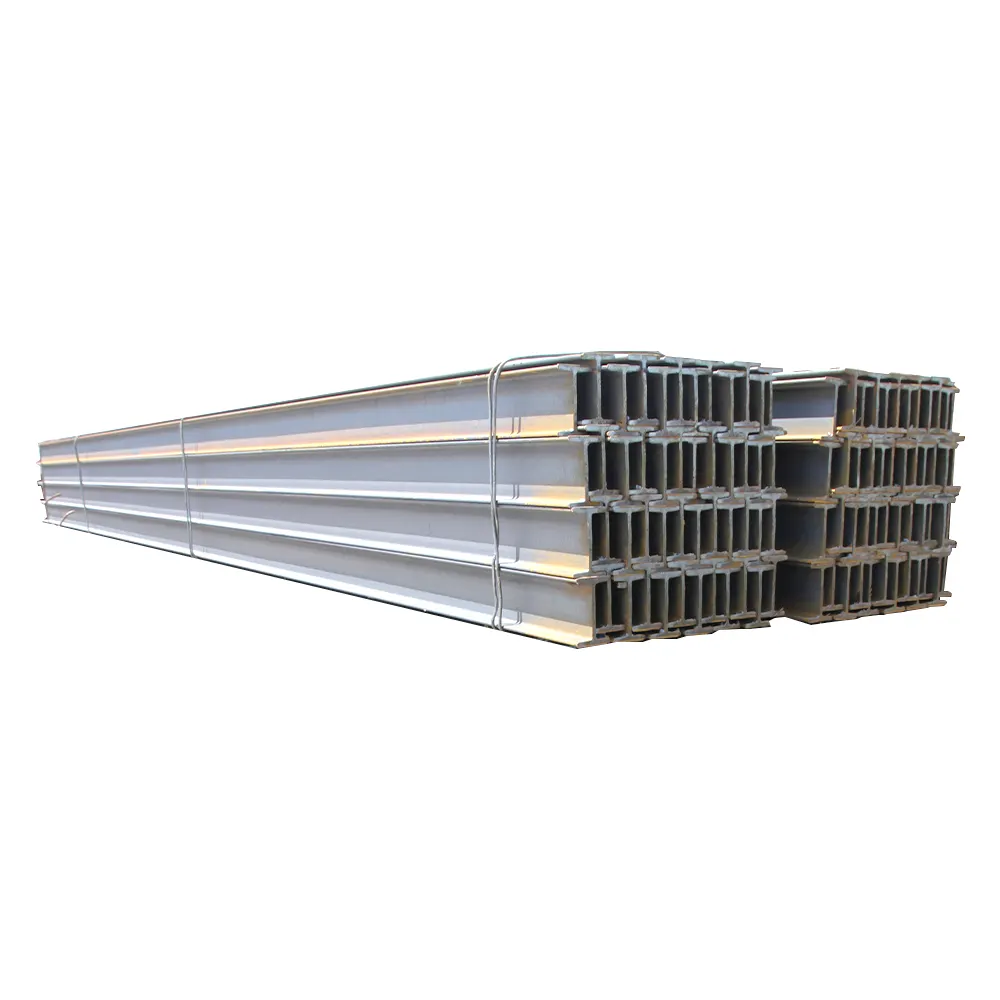

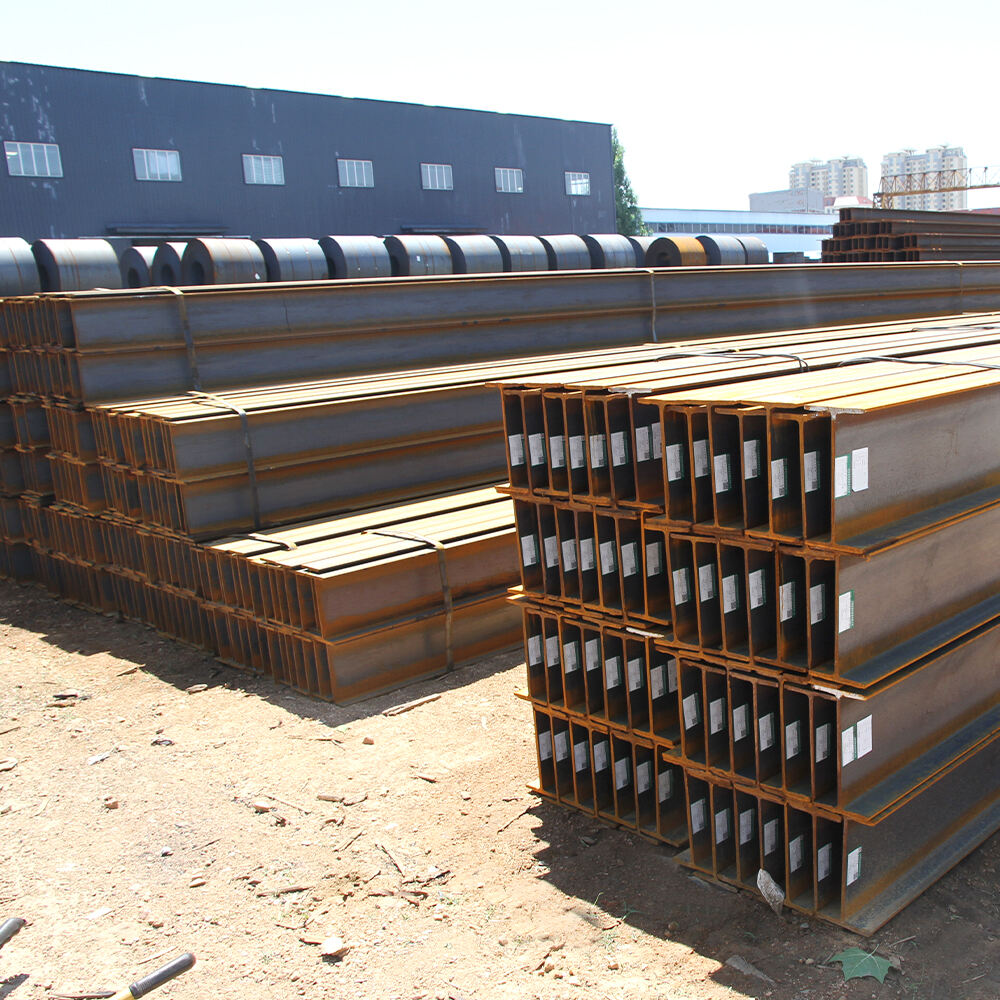

የመታል ኤች ባር፣ የተጠራው የጭ broad ጣራ ባር ወይም እንደ አይ-ባር፣ በዘመናዊ ሃገር አስተዳድር እና ምህንድስናዊነት ውስጥ የመሸከም ነገር ነው። ይህ የዋና አካል የተለዩ ኤች ቅርጽ ያለው የመስታወት ክፍል፣ በአቀባዊ የተገናኘ ሁለት ትይዩ ጣራዎች የተሰራ ነው። የዚህ ዕቅድ ጥንካሬን እየጨመረ ሲሆን የመጠን ቁሳቁስን በመጠቀም በጣም ቀላል ለመሸከም አገልግሎት ይሰጣል። እነዚህ ባሮች በሙቀት ሲሮጡ ይዘጋጃሉ፣ ቁሳቁሱ የተመሳሰለ እና የዋና አካል ጥንካሬ በሙሉ ርዝመቱ ላይ ይጠበቅባቸዋል። በተለያዩ መጠኖች እና ደረጃዎች ላይ ይገኛሉ፣ ኤች ባሮች በተለምዶ ከ4 ኢንች እስከ 44 ኢንች ድረስ ይደርሳሉ፣ የተለያዩ የህንጂ ጠብቆ ጥያቄዎችን ይያዛሉ። የመደበኛ የማምረት ሂደት የመጠን ጥራት እና የመጠን ትክክለኛነት ይጠበቅባቸዋል፣ የዋና አካል መተግበሪያዎች ለመሆን አስፈላጊ ነው። ኤች ባሮች በአቀባዊ እና አግድም መተግበሪያዎች ላይ ይፈፁ፣ ለመታጠፍ እና ለመጭመቅ ኃይሎች ምርጥ ተቃውሞ ይሰጣሉ። የእነሱ ዕቅድ ለተሻለ ጭነት አሰራር ይፈቅዳል፣ ለመስታወት መታወቂያ፣ ለከፍተኛ ረዥም የሚቆሙ ማዕከላት፣ ለኢንዱስትሪያዊ መዋቅራዊ አካላት፣ እና ለከባድ መሳሪያዎች የሚደገፍ ስርዓት አስቸጋሪ ነው። የቁሳቁስ አካል፣ በተለምዶ የከፍተኛ ደረጃ የዋና አካል ብረት፣ ለጣንካራ እና ረዥም ጊዜ የሚቆም ጥራት ይሰጣል፣ እና የተወሰኑ ተለዋዋጮች የተጨማሪ ጥራት ለማሻሻል ለመበላሸት እና ለእሳት መከላከያ ይሰጣሉ።