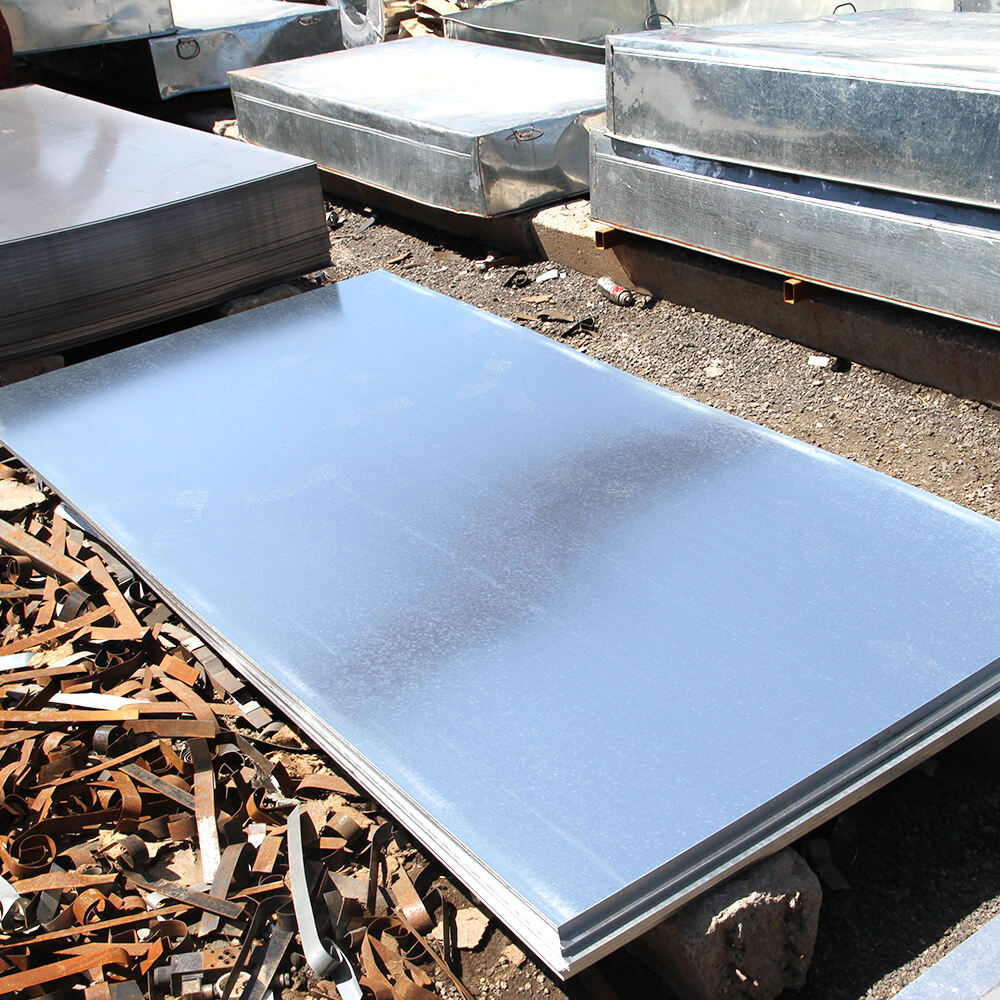

አንግል አረብ ብረት

የዝንጉት ብረት በዘመናዊ የግንባታ እና የምህንድስና መሠረታዊ መዋቅራዊ አካል ሲሆን በሁለት ጠፍጣፋ እግሮች በተሠራው የ L ቅርፅ ያለው የተቋረጠ ነው ። ይህ ሁለገብ ቁሳቁስ ልዩ ጥንካሬን ተግባራዊ ተግባራትንም ያጣምራል፤ ይህም በተለያዩ የኢንዱስትሪ መተግበሪያዎች ውስጥ አስፈላጊ አካል እንዲሆን አድርጎታል። በሙቅ ብረት በማቅለጥ የተሠራው የቅርጽ ብረት ከፍተኛ የመጎተት ጥንካሬና የላቀ የመሸከም አቅም ጨምሮ አስደናቂ ሜካኒካዊ ባህሪያትን ያሳያል። መደበኛ ዝርዝሮች በተለምዶ እኩል እና እኩል ያልሆኑ የእግር ልዩነቶችን ያካትታሉ ፣ ከ 3 ሚሜ እስከ 30 ሚሜ ወፍራም ያላቸው ፣ የተለያዩ የአተገባበር መስፈርቶችን ይፈቅዳሉ። ይህ ቁሳቁስ በውስጡ ያለው የመዋቅር መረጋጋት በግንባታ ግንባታ፣ በመደገፊያ ስርዓቶች እና በማጠናከሪያ አፕሊኬሽኖች ውስጥ በጣም ጠቃሚ እንዲሆን ያደርገዋል። የዝንጉት ብረት ዘላቂነት በተለያዩ የወለል ሕክምናዎች የተሻሻለ ሲሆን ይህም የዝገት እና የአካባቢ ሁኔታዎችን ለመቋቋም ጥሩ መቋቋም ያስችላል ። የብረት ማቀነባበሪያ ዘዴዎች ይህ ቁሳቁስ ከዋጋ አግባብነት ጋር ተዳምሮ ረጅም የአገልግሎት ዘመን ያለው ከመሆኑም ሌላ አነስተኛ የጥገና ሥራ የሚጠይቅ በመሆኑ በዘመናዊ የግንባታ ዘዴዎች ውስጥ ወሳኝ አካል ነው።