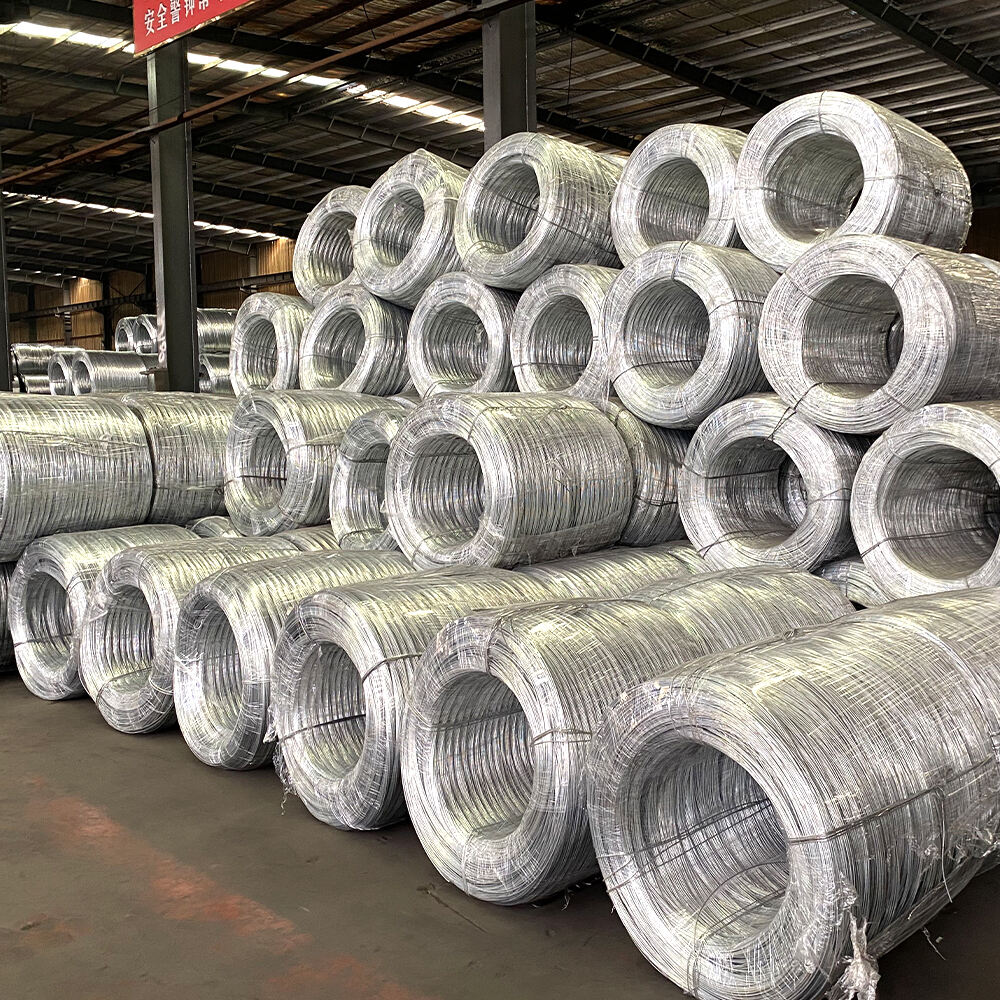

draad van vlekvrye staal

Roestvrywe staaldraad verteenwoordig 'n veelsydige en robuuste materiaal wat vir 'n verskeidenheid industriële en kommersiële toepassings ontwerp is. Hierdie hoëprestasiedraad kombineer chroom, nikkel en ander legeringselemente met staal om 'n korrosiebestande en duursame produk te skep. Vervaardigingsprosesse sluit warmwals, koudtrek en hittebehandeling in om spesifieke meganiese eienskappe te bereik. Die draad se deursnee wissel van ultra-fyn metings van 0,01 mm tot dikker variante wat 10 mm oorskry, wat verskeie toepassingsvereistes akkommodeer. Sy inherente eienskappe sluit uitstekende treksterkte, opmerklike duursaamheid en uitstekende weerstand teen verskeie omgewingsfaktore in, insluitend vog, chemikalieë en ekstreme temperature. Die draad se gladde oppervlakafwerking verseker bestendige werkverrigting in toepassings wat wissel van mediese instrumente tot industriële masjinerie. Moderne produksietegnieke stel vervaardigers in staat om strak dimensionele toleransies te handhaaf en spesifieke meganiese eienskappe te bereik wat by die eindgebruiker se vereistes aansluit. Die materiaal se inherente vermoë om sy strukturele integriteit onder wisselende toestande te behou, maak dit onskatbaar in kritieke toepassings waar betroubaarheid van uiterste belang is.