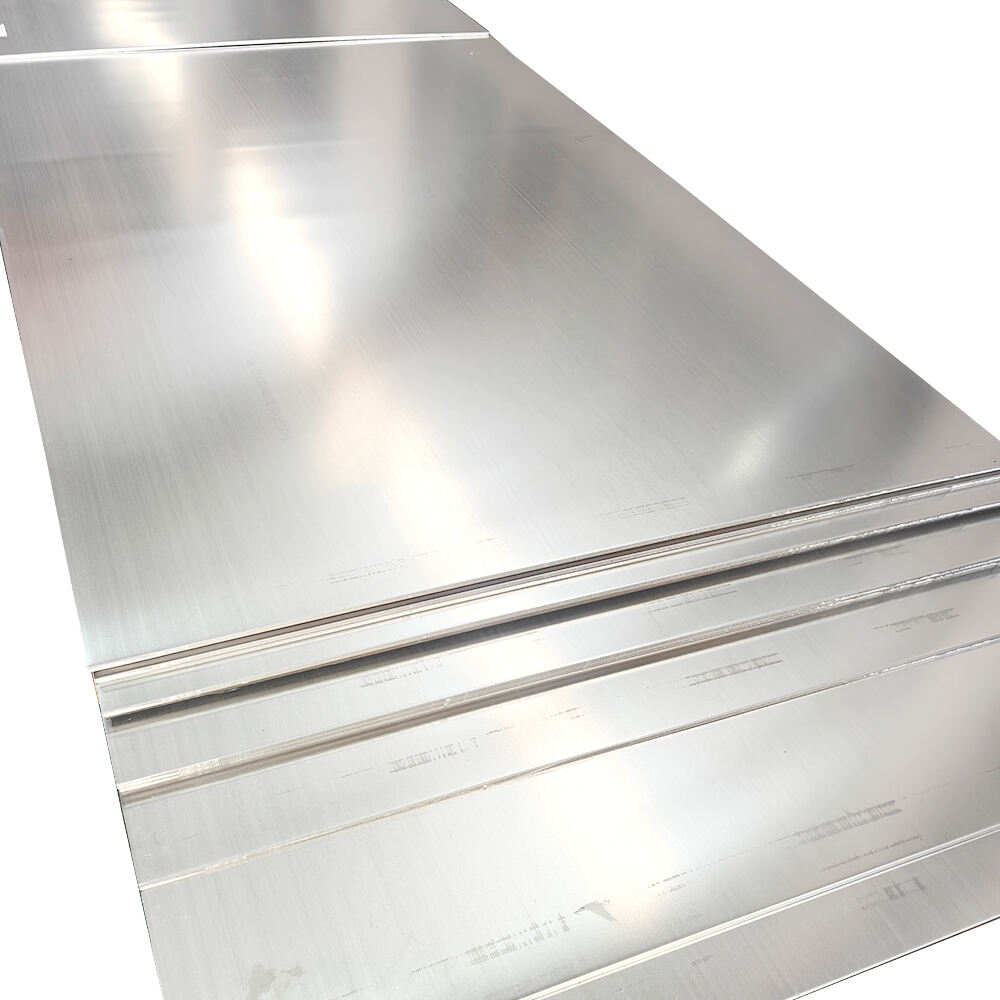

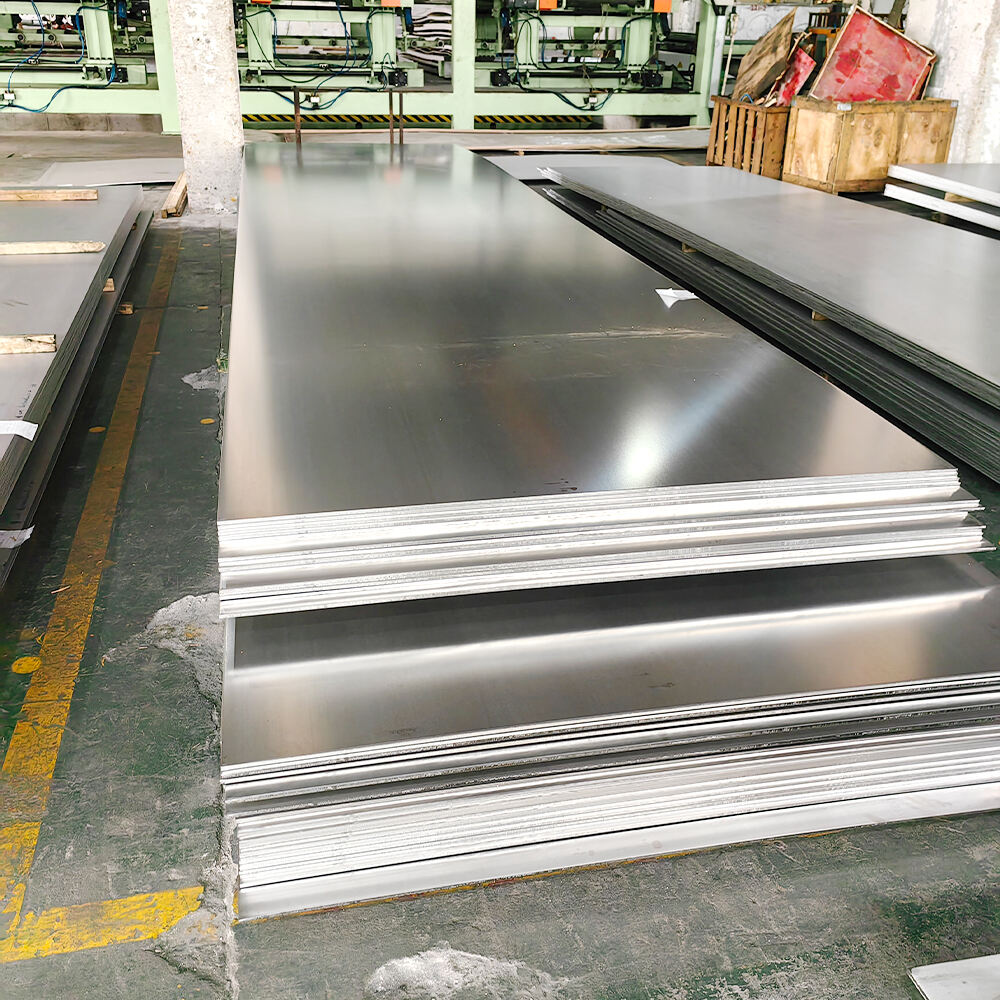

vlekvrye staalplaat

Roestvrywe staalplaat verteenwoordig 'n veelvuldig gebruikte en duursame materiaal wat die moderne vervaardigings- en konstruksie-industrieë omgeskakel het. Hierdie uitstekende materiaal kombineer chroom, nikkel en ander legeringselemente met staal om 'n korrosiebestande oppervlak te skep wat sy integriteit behou onder uiteenlopende omgewingsomstandighede. Die plaat se merkwaardige eienskappe sluit uitstekende hittebestandigheid in, met die vermoë om temperature te weerstaan wat wissel van subnul tot bo 800°C, afhanklik van die graad. Beskikbaar in verskeie diktes, afwerking en grade, bied roestvrywe staalplate ongekende buigsaamheid in toepassings. Die materiaal se nie-poreuse oppervlak maak dit van nature higiënies, wat dit ideaal maak vir mediese en voedselverwerkingsomgewings. Moderne vervaardigingstegnieke verseker presiese diktebeheer en uitstekende oppervlakkwaliteit, terwyl gevorderde rolprosesse plate produseer met uitstekende platheid en dimensionele stabiliteit. Hierdie plate kan met verskeie metodes vervaardig word, insluitend sny, sweis en vorm, sonder om hul korrosiebestandigheid of strukturele integriteit te kompromitteer. Die materiaal se volhoubare eienskappe is ewe indrukwekkend, aangesien roestvrywe staal 100% herwinbaar is en sy eienskappe behou deur veelvuldige herwinningsiklusse.