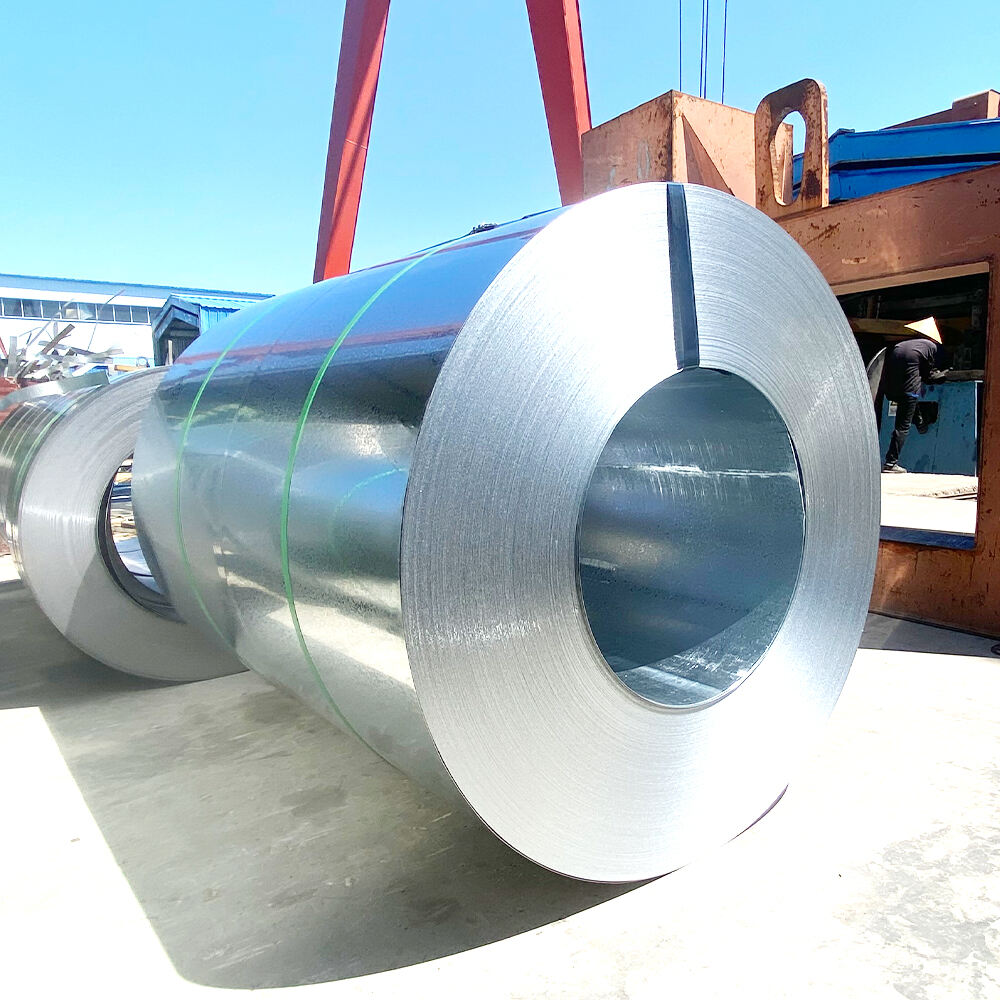

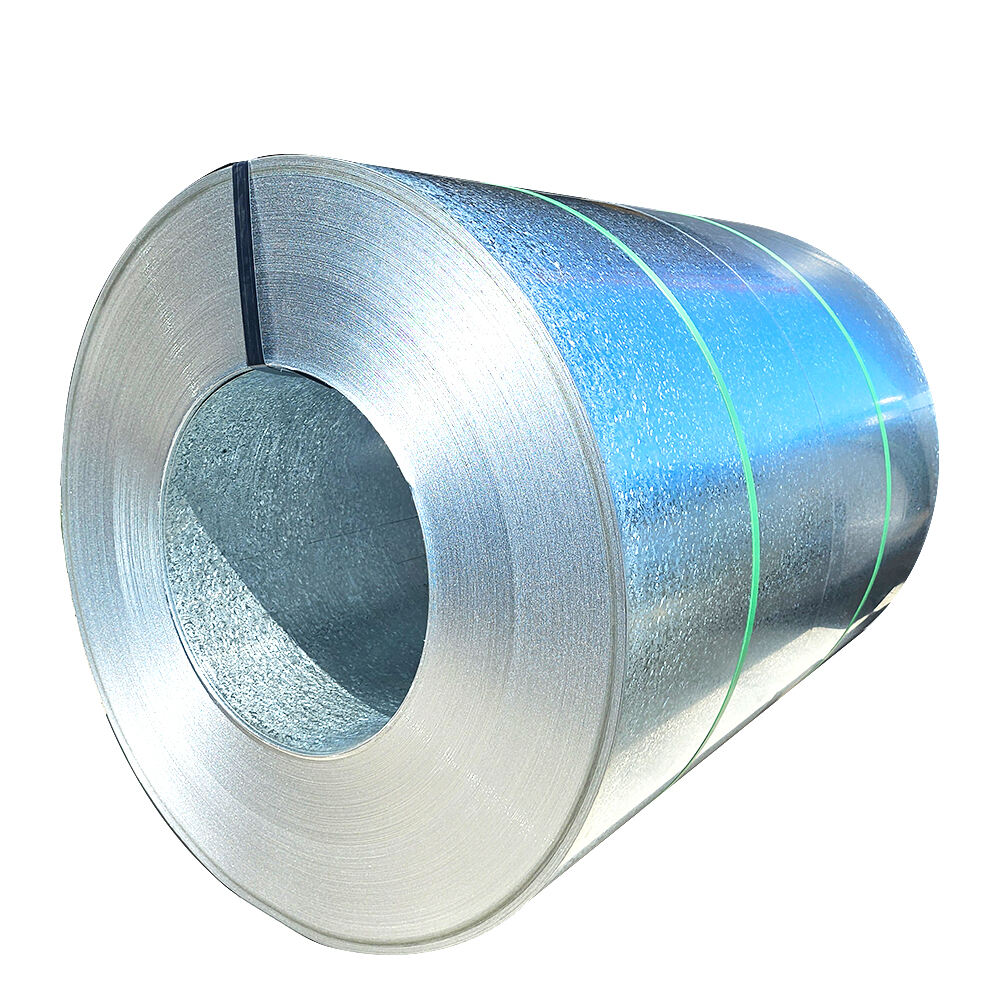

spangle gegalvaniseerde staal

Skitter galvaniseerde staal verteenwoordig 'n verfynde metallurgiese prestasie wat duursaamheid met estetiese aantrekkingskrag verenig. Hierdie gespesialiseerde staal ondergaan 'n snydip-galvaniseringsproses waar smeltende sink op die staaloppervlak aangewend word, wat 'n kenmerkende kristallyne patroon vorm wat bekend staan as skitter. Die grootte en voorkoms van hierdie skitter kan beheer word deur die koelkoers en chemiese samestelling noukeurig te manipuleer. Die resulterende bedekking bied uitstekende korrosiebestandigheid terwyl dit die strukturele integriteit van die basisstaal behou. Tydens die vervaardigingsproses beweeg die staal deur 'n smeltende sinkbad by temperature rondom 450°C, wat die sink toelaat om metallurgies met die staalsubstraat te bind. Dit skep verskeie lae van sink-ysterlegerings, met 'n suiwer sinkbuite laag wat die kenmerkende skitterpatroon vorm. Die bedekking se dikte wissel gewoonlik tussen 20 en 100 mikron, afhangende van die beoogde toepassing. Hierdie veelvuldige materiaal vind uitgebreide gebruik in konstruksie, motorvervaardiging en industriële toepassings waar beide beskermende eienskappe en visuele aantrekkingskrag belangrik is.